Ternary carbide/AlSi7Mg composite material and application thereof

A ternary carbide and composite material technology, applied in the field of aluminum-based composite materials, can solve the problems of high corrosion resistance, low thermal cracking tendency, general machinability, etc., achieve obvious strengthening effect, improve performance, and excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

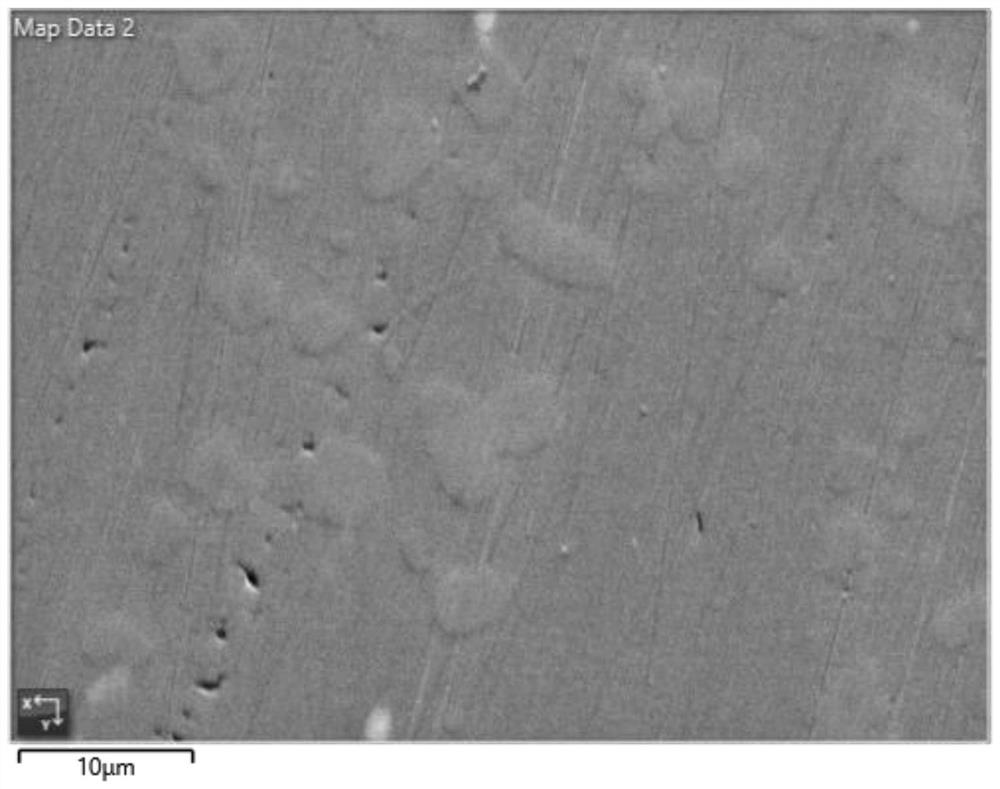

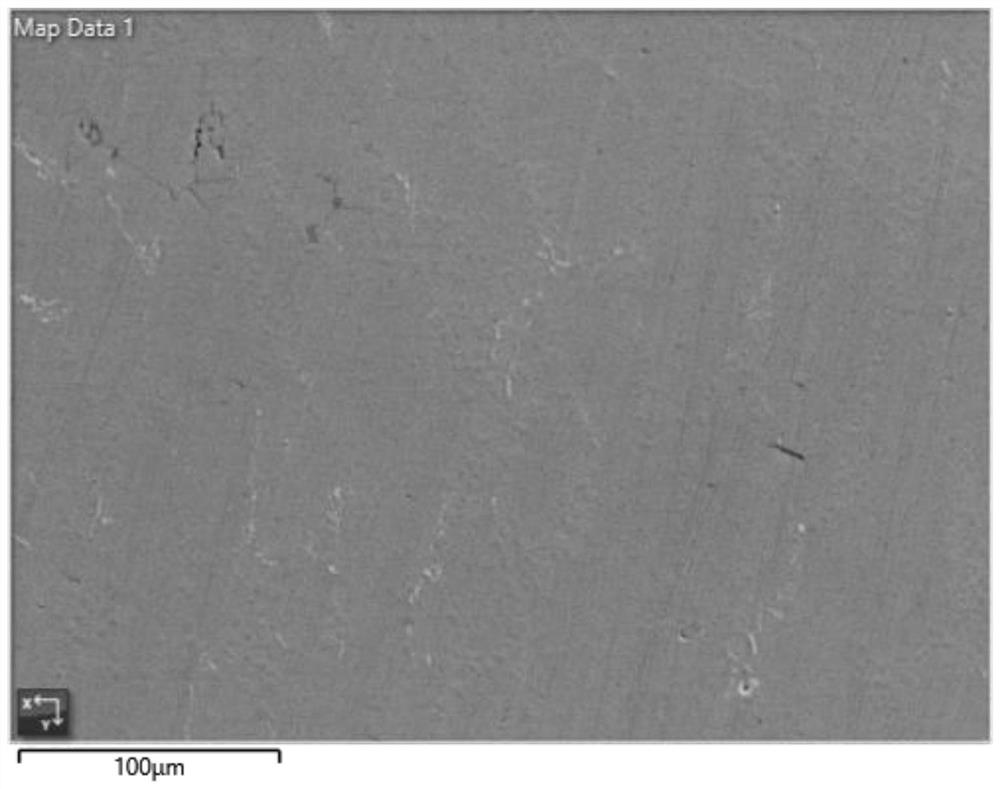

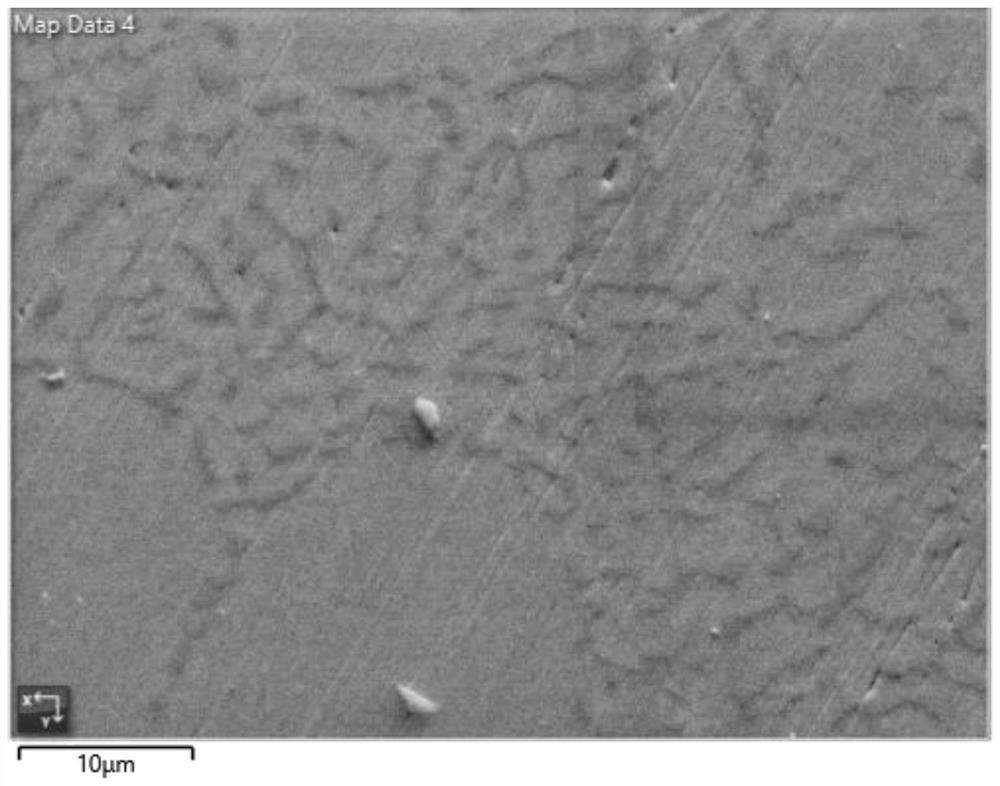

Image

Examples

Embodiment 1

[0029] A ternary carbide / AlSi7Mg composite material, comprising the following components, in percent by weight:

[0030]

[0031] Among them, Si is 7.0wt%, Mg is 0.45%, and the balance is Al.

[0032] The preparation method is as follows: mix (Ti0.5, W0.25, Mo0.25) C powder with AlSi7Mg aluminum alloy powder (AlSi7Mg aluminum alloy powder accounts for 10% of the AlSi7Mg aluminum alloy), and press it into a green embryo under a pressure of 100 MPa; The mixed powder was sintered in vacuum at a temperature of 520 °C to obtain a ternary carbide / AlSi7Mg intermediate alloy; the AlSi7Mg alloy was added to a graphite crucible, heated to melting in a resistance furnace, and then modified Al-10Sr, refiner AlTiB and Ternary carbide / AlSi7Mg master alloy; at 760 ° C, the above alloy melt was kept for 30 minutes, stirred for 5 minutes, and the stirring speed was 40 r / min, and then held for 60 minutes; finally the above alloy melt was degassed and refined. The melt temperature When the t...

Embodiment 2

[0034] A ternary carbide / AlSi7Mg composite material, comprising the following components, in percent by weight:

[0035]

[0036] Among them, Si is 7.0wt%, Mg is 0.45%, and the balance is Al.

[0037] The preparation method is as follows: mix (Ti0.5, W0.25, Mo0.25) C powder with AlSi7Mg aluminum alloy powder (AlSi7Mg aluminum alloy powder accounts for 50% of the AlSi7Mg aluminum alloy), and press it into a green embryo under a pressure of 120 MPa; The mixed powder was sintered in vacuum at a temperature of 530 °C to obtain a ternary carbide / AlSi7Mg intermediate alloy; the AlSi7Mg alloy was added to a graphite crucible, heated to melting in a resistance furnace, and then modified Al-10Sr, refiner AlTiB and Ternary carbide / AlSi7Mg master alloy; at 710 ° C, the above alloy melt was kept for 20 minutes, stirred for 3 minutes, and the stirring speed was 40 r / min, and then held for 60 minutes; finally the above alloy melt was degassed and refined. The melt temperature When the t...

Embodiment 3

[0039] A ternary carbide / AlSi7Mg composite material, comprising the following components, in percent by weight:

[0040]

[0041]

[0042] Among them, Si is 7.0wt%, Mg is 0.45%, and the balance is Al.

[0043] The preparation method is as follows: mix (Ti0.5, W0.25, Zr0.25) C powder with AlSi7Mg aluminum alloy powder (AlSi7Mg aluminum alloy powder accounts for 15% of the AlSi7Mg aluminum alloy), and press it into a green embryo under a pressure of 120 MPa; The mixed powder was sintered in vacuum at a temperature of 540 °C to obtain a ternary carbide / AlSi7Mg master alloy; the AlSi7Mg alloy was added to a graphite crucible, heated to melting in a resistance furnace, and then modified Al-10Sr, refiner AlTiB and Ternary carbide / AlSi7Mg master alloy; at 750 ℃, the above alloy melt was kept for 30 minutes, stirred for 5 minutes, the stirring speed was 40 r / min, and then held for 60 minutes; finally the above alloy melt was degassed and refined after the melt temperature When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com