PLD preparation method of large-area molybdenum ditelluride

A molybdenum ditelluride, large-area technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problem of difficulty in preparing high-quality large-area molybdenum ditelluride, save raw materials, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content of the present invention, the present invention will be described in detail with reference to the accompanying drawings and specific embodiments.

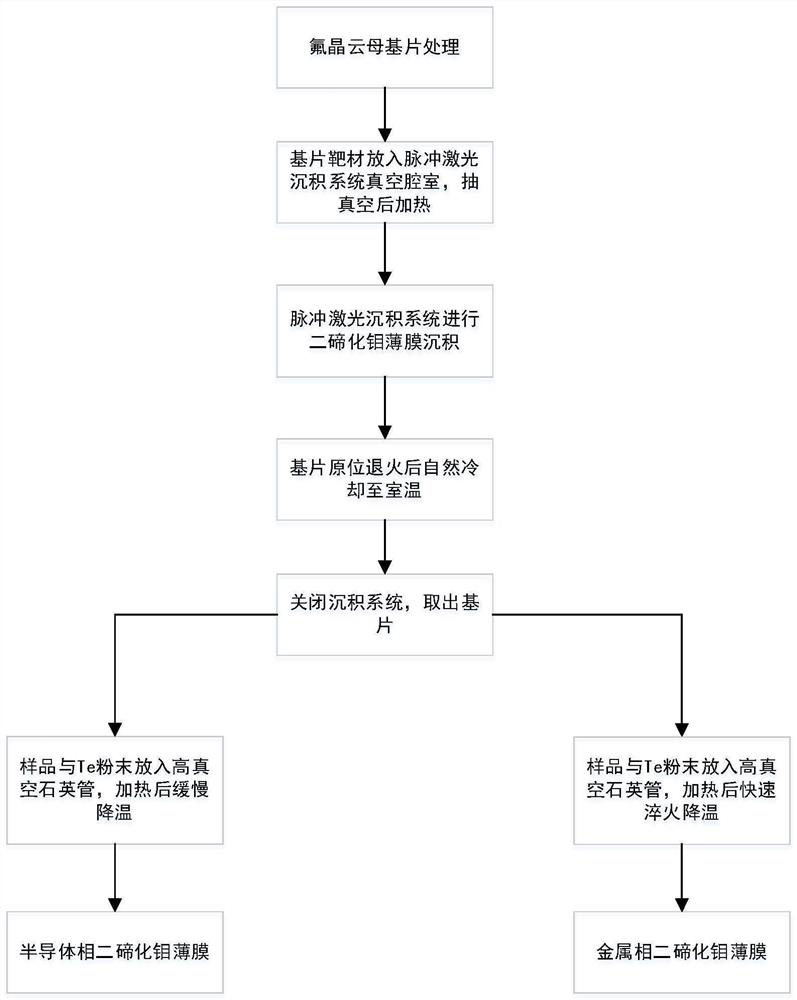

[0029] In the present invention, the molybdenum ditelluride film is first deposited on the substrate by a pulsed laser deposition system, and then the deposited film and Te powder are packaged into a vacuum quartz tube, and annealed at high temperature. According to different annealing conditions, 2H-MoTe can be prepared 2 and 1T’-MoTe 2 These two films of different phases, the overall preparation steps are as follows figure 1 shown.

[0030] Step 1: The fluorocrystalline mica substrate is treated with acetone, alcohol and deionized water. The method used in this embodiment is: first ultrasonically clean the fluorocrystalline mica substrate in acetone and anhydrous ethanol for 5 minutes, and then The cleaned substrates were soaked in deionized water for 20 minutes.

[0031] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com