Composite positive electrode material, battery positive electrode, lithium battery and application thereof

A composite positive electrode material and battery positive electrode technology, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of poor conductivity and limit the high energy density of lithium-sulfur batteries, so as to delay polarization and improve Effects of long cycle stability and Coulomb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

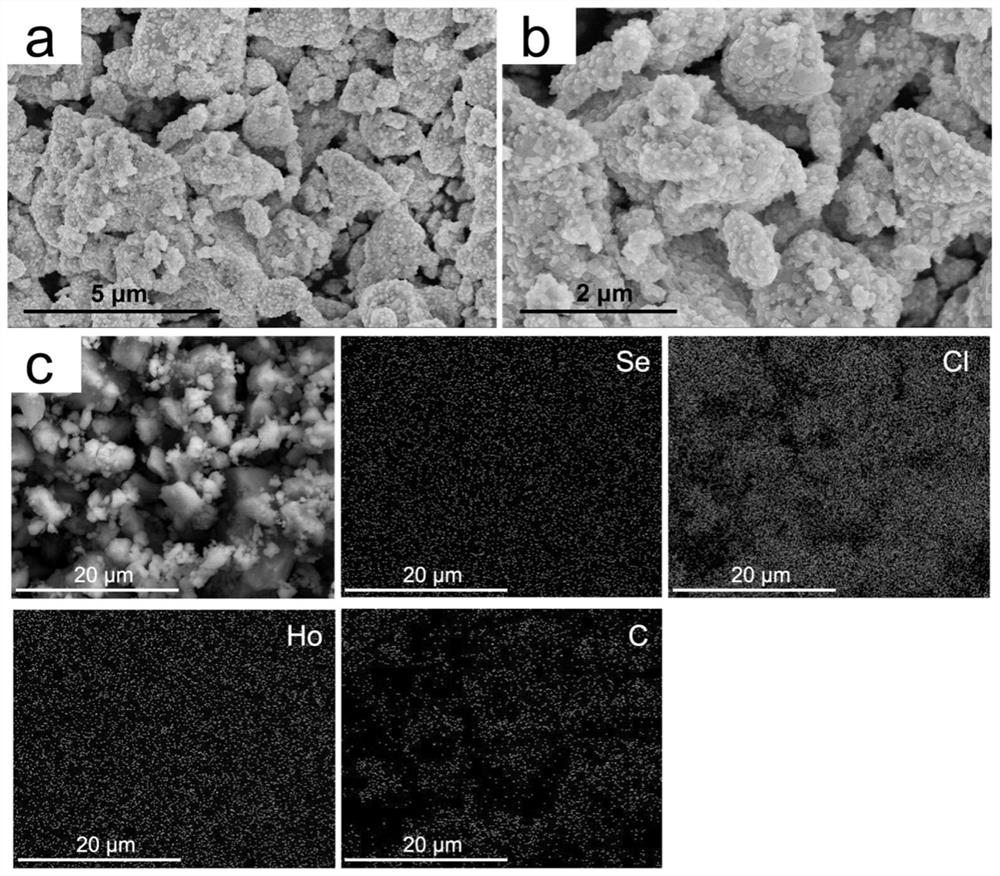

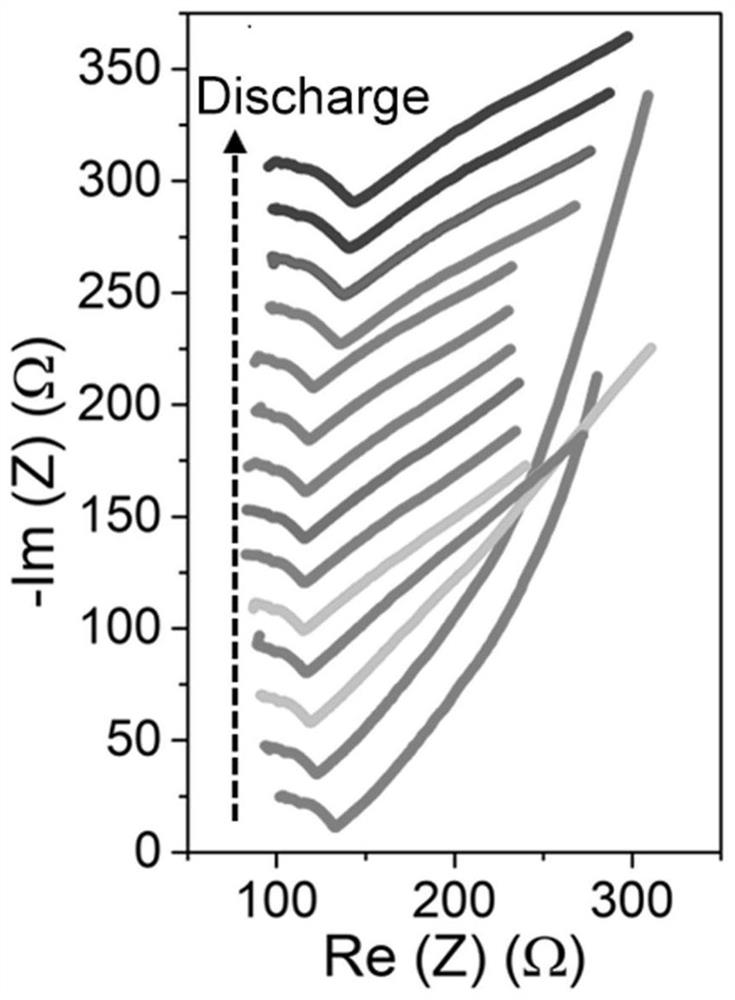

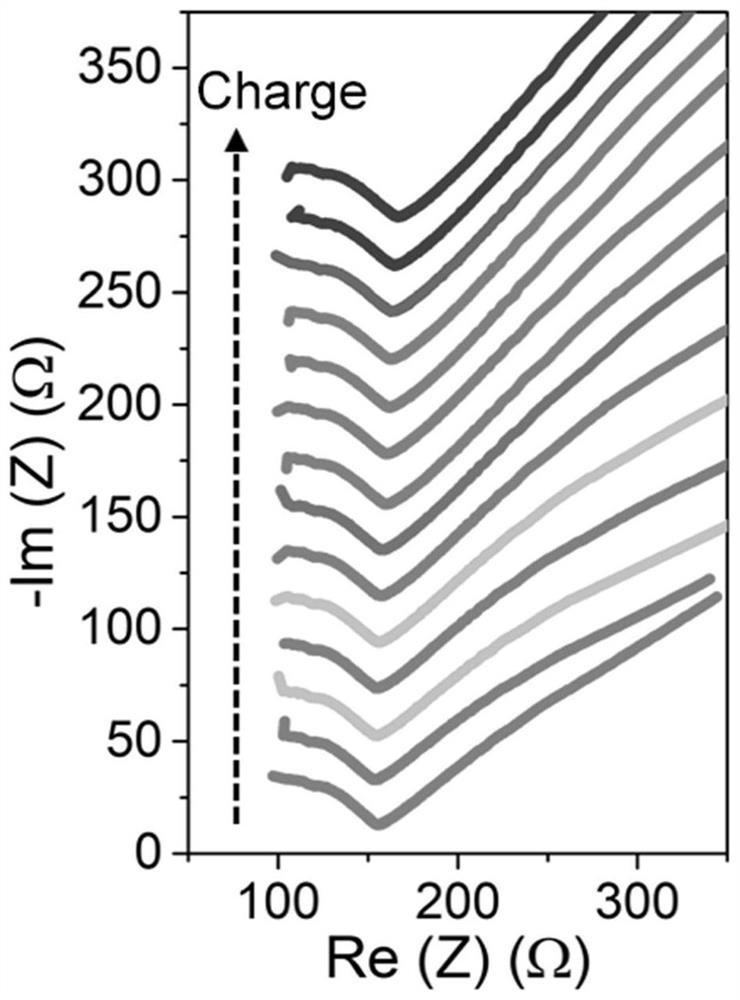

[0060] This embodiment provides a composite positive electrode material, the positive electrode active material is Se (x=1), the first coating layer material is acetylene black conductive material, and the second coating layer is Li 0.455 Ho 0.182 Cl (M=Ho, b=0.545, b=0.182) chloride material (Se, the mass ratio of the first cladding layer and the second cladding layer is 5:1:5, and the active content of Se accounts for the content of the entire composite cathode as 45.5wt%) preparation method is as follows:

[0061] Weigh 0.5 g of commercially purchased elemental selenium powder and 0.05 g of acetylene black, respectively, and then compound them by ball milling. The ball milling speed is 400 rpm and the ball milling time is 5 hours. The obtained sample is modified with the first coating layer. Se material. At the same time, the commercially purchased anhydrous LiCl and anhydrous HoCl were prepared by eutectic reaction. 3 The eutectic reaction was carried out according to t...

Embodiment 2

[0065] This embodiment provides a composite positive electrode material, and the positive electrode active material is S 0.25 Se 0.75 (x=0.75), the material of the first cladding layer is carbon nanotube conductive material, and the second cladding layer is Li 0.5 In 0.167 Cl(M=In, b=0.5, c=0.167) chloride material (S 0.25 Se 0.75 , the mass ratio of the first cladding layer and the second cladding layer is 10:1:5, S 0.25 Se 0.75 The active content accounts for 62.5wt% of the entire composite positive electrode) and the preparation method is as follows:

[0066] Weigh 0.592 grams of commercially purchased elemental selenium powder and 0.16 grams of elemental sulfur powder, respectively, and grind them with a mortar for 30 minutes to uniformity. Then, pour the ground samples into a single-head sealed quartz tube, and seal it by vacuum sealing. Then put it in a muffle furnace and react at 350 degrees Celsius for 24 hours, then take it out in the glove box and grind it into...

Embodiment 3

[0069] This embodiment provides a composite positive electrode material, and the positive electrode active material is P 4 S 30 (n=20), the material of the first cladding layer is porous carbon conductive material, and the material of the second cladding layer is Li 0.5 Y 0.167 Cl(M=Y, b=0.5, c=0.167) chloride material (P 4 S 30 , the mass ratio of the first cladding layer and the second cladding layer is 10:1:11, and the Se active content accounts for 45.5wt% of the entire composite positive electrode) The preparation method is as follows:

[0070] Weigh 0.124 g of commercially purchased elemental red phosphorus and 0.96 g of elemental sulfur powder, respectively, and grind them in a mortar for 30 minutes until uniform, then pour the ground samples into a single-head sealed quartz tube, and seal it by vacuum sealing. Then put it in a muffle furnace and react at 350 degrees Celsius for 24 hours, then take it out in the glove box and grind it into powder to obtain P 4 S 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com