Super-hydrophobic coating as well as preparation method and application thereof

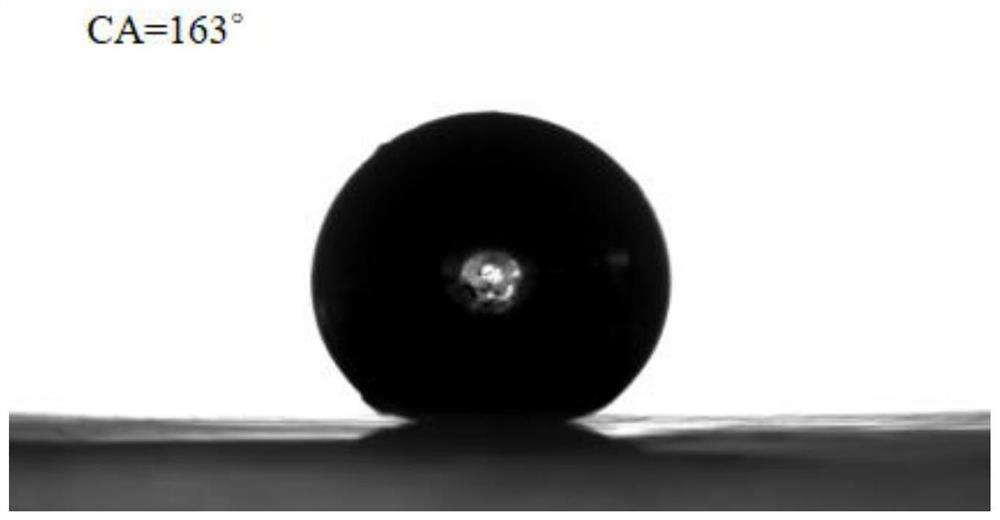

A technology of super-hydrophobic coating and composite intermediate layer, which is applied in coating, general water supply saving, sustainable manufacturing/processing, etc. It can solve the problems of poor stability of super-hydrophobic surface and difficult to realize underwater practical application, etc., to achieve improved stability properties, excellent anti-corrosion performance, and the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

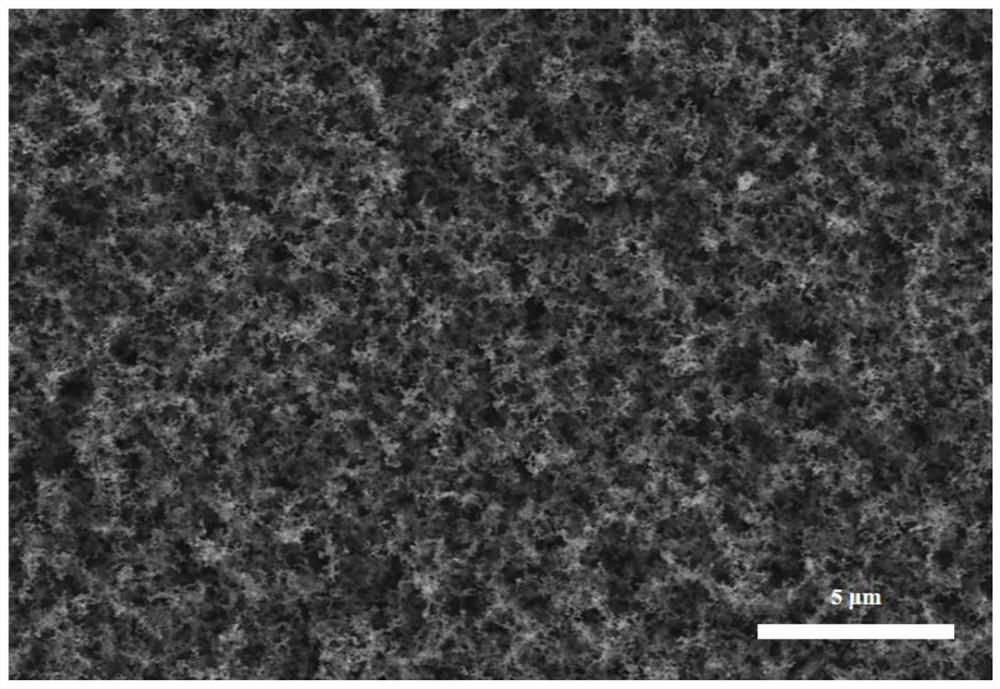

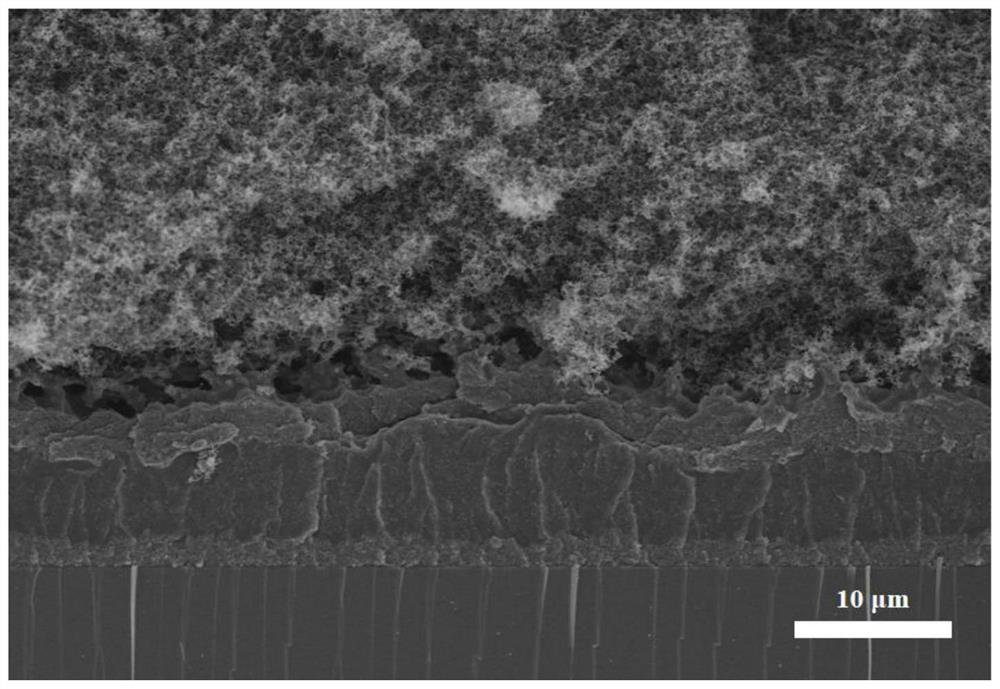

[0038] A preparation method of a superhydrophobic coating, comprising the following steps:

[0039] (1) the substrate is placed on the top of the candle flame, and the candle soot deposition is carried out to form a pre-soot layer;

[0040] (2) after mixing the coupling agent solution and the low surface energy solution, drop into the surface of the soot layer, and carry out semi-curing treatment to obtain a semi-cured composite intermediate layer;

[0041] (3) coating the polymer material solution on the surface of the semi-cured composite intermediate layer;

[0042] (4) place the sample obtained in step (3) above the candle flame, carry out candle soot deposition, and form a polymer soot layer;

[0043] (5) After drying the sample obtained in step (4) at 50-300° C. for 0.5-3 hours, after curing, a super-hydrophobic coating is formed on the surface of the substrate.

[0044] Superhydrophobic surfaces in nature and man-made bionic superhydrophobic surfaces have poor stabili...

Embodiment 1

[0072] A preparation method of a superhydrophobic coating, comprising the following steps:

[0073](1) Prepare low surface energy solution, coupling agent solution and polymer material solution: dissolve polydimethylsiloxane in n-heptane solution, stir to obtain low surface energy solution; mix coupling agent KH-570 In the ethanol solution, hydrolyze with deionized water, use acetic acid to adjust the pH of the mixed solution until the pH is 4, and continue stirring the obtained solution for one hour to obtain a coupling agent solution; take 10 ml of tetrahydrofuran (THF) solution, weighed The amount of 0.1g thermoplastic polyurethane powder was dissolved in the solution, and the solution was continuously stirred to obtain a polymer material solution;

[0074] Cut the substrate (aluminum sheet) for cleaning and set aside, light a candle, and after the candle flame is stable, place the aluminum sheet in the middle flame position 0.5cm above the candle and move it back and forth...

Embodiment 2

[0080] (1) Preparation of low surface energy solution, coupling agent solution and polymer material solution: dissolving heptadecafluorodecyltriethoxysilane solution in ethanol solution, hydrolyzing with deionized water, and stirring for 24 hours to obtain low surface energy solution Surface energy solution; mix the coupling agent KH-560 in ethanol solution, hydrolyze with deionized water, use acetic acid to adjust the pH of the mixed solution until the pH is 4, and continue stirring the obtained solution for one hour to obtain the coupling 5 ml of tetrahydrofuran (THF) solution and 5 ml of N,N-dimethylformamide (DMF) solution were mixed uniformly, 5 g of polyester powder was weighed and dissolved in the mixed solution, and the solution was continuously stirred to obtain a polymer material solution;

[0081] Clean the substrate (glass) for later use, light a candle, and after the candle flame is stable, place the glass in the middle flame position 2cm above the candle and move ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com