Efficient and energy-saving liquid sugar production process method

A production process, high-efficiency and energy-saving technology, applied in the production of sucrose, sugar production, purification by physical methods, etc., can solve the problems of unfavorable production efficiency, different quality of sucrose, unable to meet the requirements of high-precision process production, etc., and achieve decolorization. Thorough, good decolorization effect, excellent gas adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

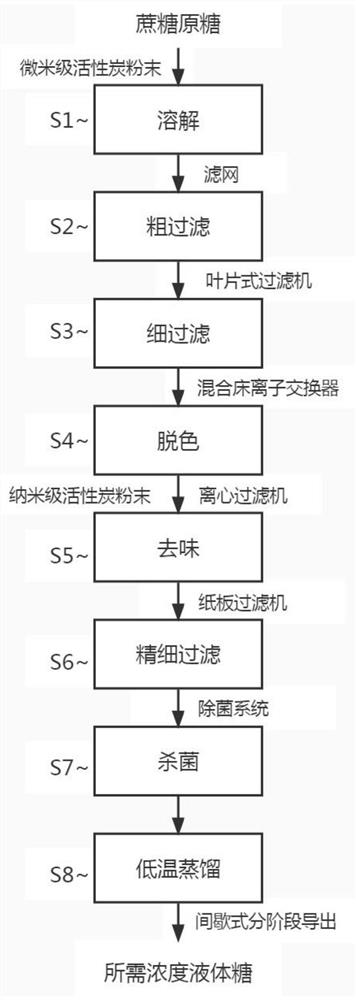

[0031] like figure 1 As shown, a high-efficiency and energy-saving liquid sugar production process method comprises the following steps:

[0032] A high-efficiency and energy-saving liquid sugar production process method, comprising the following steps:

[0033] S1. Dissolving: Mix sucrose raw sugar and micron-sized activated carbon powder in a mass ratio of 1000:3-5 and dissolve in deionized water. Heat to 50-65°C and stir evenly to obtain a mixture of sucrose and activated carbon. ;

[0034] S2. Coarse filtration: filter the mixed solution through a filter screen to obtain a filtrate mixed with activated carbon powder; in step S2, the filter screen adopts a 40-200 mesh screen.

[0035] S3, fine filtration: filter the filtrate through a leaf filter to obtain a primary sugar solution; in step S3, the filtration accuracy of the leaf filter is 50-400um.

[0036] S4, decolorization: adding the primary sugar solution to a mixed-bed ion exchanger for decolorization to obtain a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com