All-solid-state thick-film lithium battery with alloy interface layer and preparation method of all-solid-state thick-film lithium battery

An all-solid-state, lithium battery technology, used in lithium batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of direct contact between positive and negative electrodes, lack of thick-film negative electrodes, complicated processes, etc., to reduce impact, volume and The effect of smooth change of surface tension and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

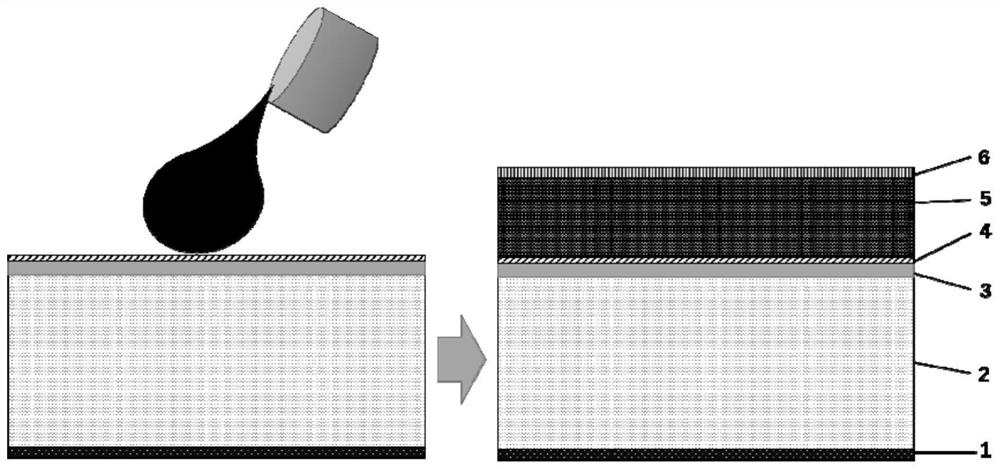

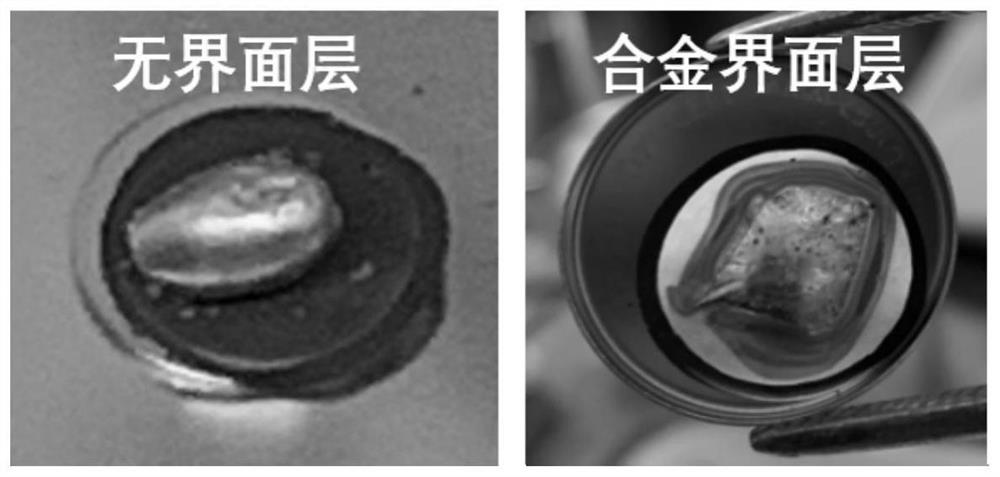

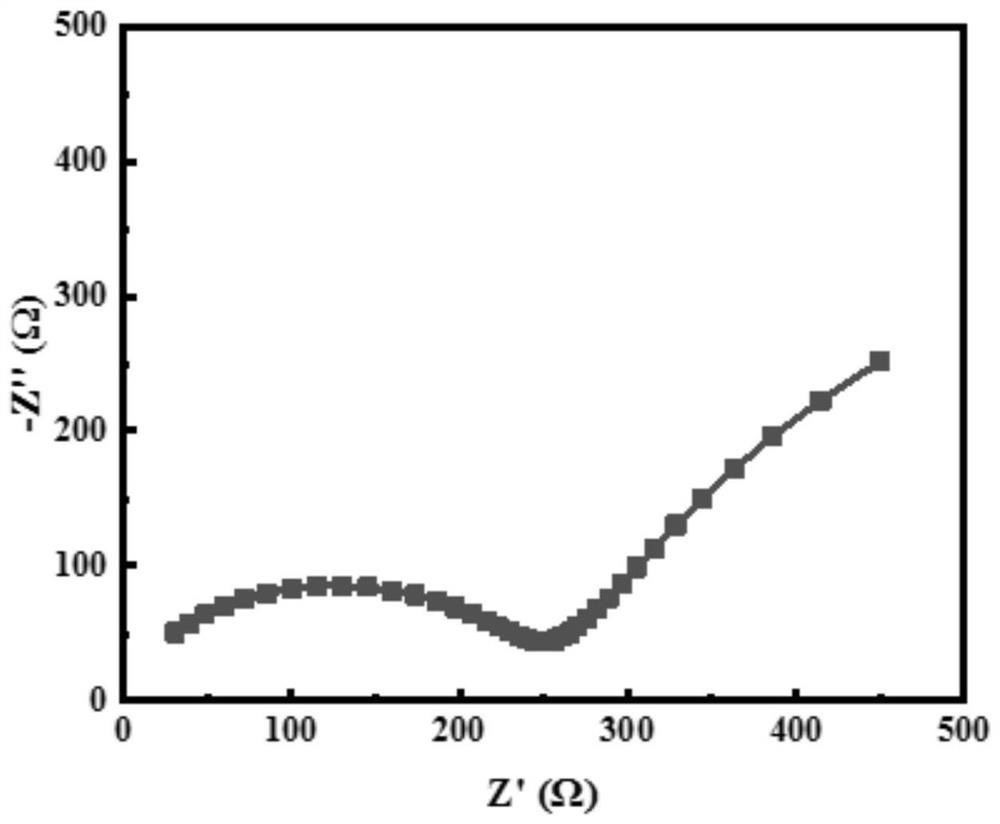

[0036] This embodiment provides an all-solid-state thick-film lithium battery with an alloy interface layer, the structure is as follows figure 1As shown, among them: 1. Positive electrode current collector; 2. Thick film positive electrode; 3. Electrolyte film; 4. Alloy interface layer; 5. Thick film negative electrode; 6. Negative electrode current collector. The molten lithium reacts with the metal thin film layer to form a lithium alloy interface layer, and simultaneously forms a thick-film lithium negative electrode integrated with the alloy interface layer after cooling.

[0037] Its preparation method includes:

[0038] (1) The active material LiFePO 4 , Conductive agent acetylene black, binder polyethylene oxide and solid electrolyte LLZO are mixed evenly in the solvent, the positive electrode paste is printed on the positive current collector aluminum foil by the casting method printing equipment, and vacuum dried to obtain a 180 μm thick film positive electrode ; ...

Embodiment 2

[0043] This embodiment provides an all-solid-state thick-film lithium battery with an alloy interface layer, the preparation method of which includes:

[0044] (1) The active material LiFePO 4 , Conductive agent acetylene black, binder polyethylene oxide and solid electrolyte LLZO are mixed evenly in the solvent, the positive electrode paste is printed on the positive current collector aluminum foil by the casting method printing equipment, and vacuum dried to obtain a 180 μm thick film positive electrode ;

[0045] (2) 6 μm LLZO thin films were prepared on the thick film cathode by magnetron sputtering;

[0046] (3) A 500 nm Ag interface layer was prepared on the thin film electrolyte by magnetron sputtering;

[0047] (4) Under the condition that the Ag layer is kept at 300°C, the molten metal lithium is poured on the Ag interface layer, and the amount of poured metal lithium is controlled. A lithium alloy interface layer is formed, and a thick-film anode having an integra...

Embodiment 3

[0051] This embodiment provides an all-solid-state thick-film lithium battery with an alloy interface layer, the preparation method of which includes:

[0052] (1) The active material LiFePO 4 , Conductive agent acetylene black, binder polyethylene oxide and solid electrolyte LLZO are mixed evenly in the solvent, the positive electrode paste is printed on the positive current collector aluminum foil by the casting method printing equipment, and vacuum dried to obtain a 180 μm thick film positive electrode ;

[0053] (2) Preparation of 8 μm Li on the thick-film cathode by electron beam evaporation 3 PO 4 film;

[0054] (3) A 1 μm Mg interface layer was prepared on the thin film electrolyte by magnetron sputtering;

[0055] (4) Under the condition of keeping the Mg layer at 250 °C, pour the molten metal lithium on the Mg interface layer, and control the amount of the poured metal lithium. A lithium alloy interface layer is formed, and a thick-film anode having an integrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com