Metal compound diaphragm as well as preparation method and application thereof

A metal compound and diaphragm technology, applied in the field of metal compound diaphragm and its preparation, can solve the problems of not being able to fundamentally inhibit the growth of lithium dendrites, failing to reduce battery performance attenuation, and being punctured, so as to avoid battery corrosion, Effect of improving electrochemical performance and increasing tortuosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

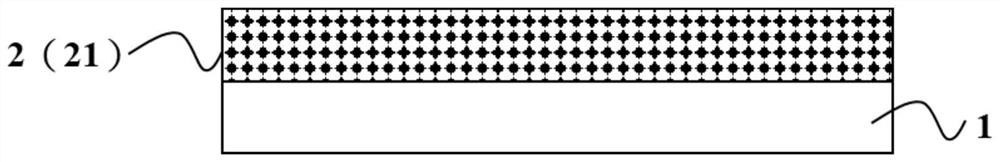

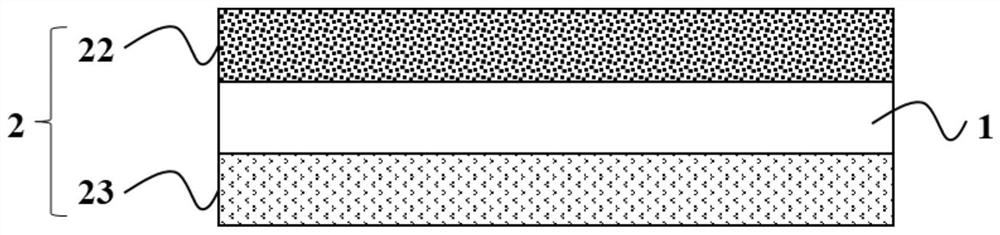

[0054] The preparation method of the metal compound separator according to the first embodiment of the present invention is further described below, which includes: a mixing step; and a drying coating step.

[0055] During mixing, the heat-resistant particles, metal oxide particles and solvent are mixed to obtain a dispersion. The use of a solvent can disperse the heat-resistant particles and the metal oxide particles so that they can subsequently be distributed in a desired manner on one side of the base film (1), an example of the solvent can be, but not limited to, N,N-dimethyl One or more of formamide, N-methylpyrrolidone, acetonitrile, ethanol, and isopropanol. Furthermore, in order to improve the adhesion of the coating (2), the dispersion liquid may further comprise a binder. Under this condition, the use of a solvent can dissolve the binder more.

[0056] During dry coating, the dispersion liquid is coated on one side of the base film (1) and dried to obtain a metal ...

Embodiment 1

[0073] In the separator of this embodiment, the thickness of the base film is 9 μm, and the thickness of the coating layer is 2 μm.

[0074] First, alumina heat-resistant particles with a particle size of 100 nm, manganese oxide metal oxide particles with a particle size of 50 nm, a PVDF binder and a solvent are mixed to obtain a dispersion. The solvent is N,N-dimethylformamide, N-methylformamide One or more of pyrrolidone, acetonitrile, ethanol, and isopropanol.

[0075] Next, the dispersion liquid was applied to one side of the polyethylene base film and then dried to obtain a separator.

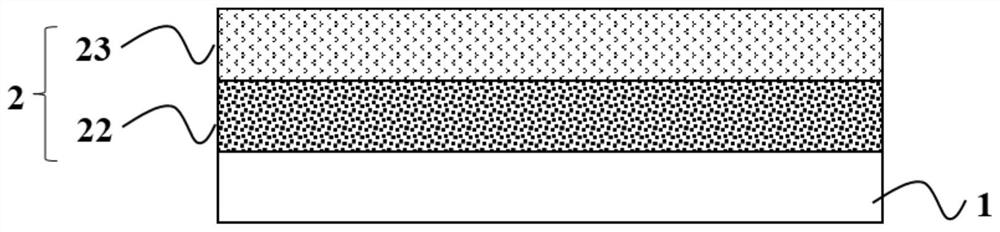

Embodiment 2

[0077] In the separator of this embodiment, the thickness of the base film is 9 μm, and the thickness of the coating layer is 4 μm.

[0078]First, the alumina heat-resistant particles with a particle size of 100 nm, the PVDF binder and the solvent are mixed to obtain a first dispersion liquid, and the manganese oxide metal oxide particles with a particle size of 50 nm, the PVDF binder and the solvent are mixed to obtain a second dispersion liquid liquid. The solvent is one or more of N,N-dimethylformamide, N-methylpyrrolidone, acetonitrile, ethanol, and isopropanol.

[0079] Next, the first dispersion liquid is coated on one side of the polyethylene base film and then dried, and the second dispersion liquid is coated on the same side of the polyethylene base film and then dried to obtain a separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com