Flue gas denitration device for solid waste treatment

A denitrification and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of insufficient gas reaction, inability to remove soot particles, and insufficient denitration, etc., to achieve the effect of easy inflow treatment, convenient centralized treatment, and good gas treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

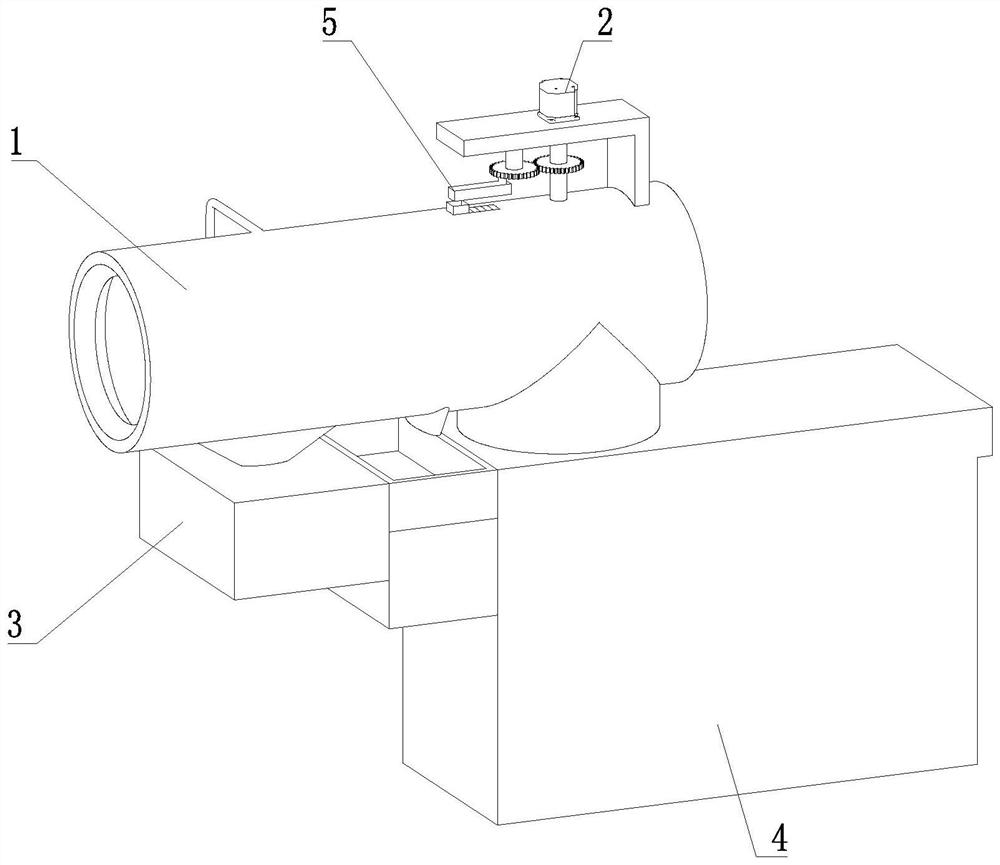

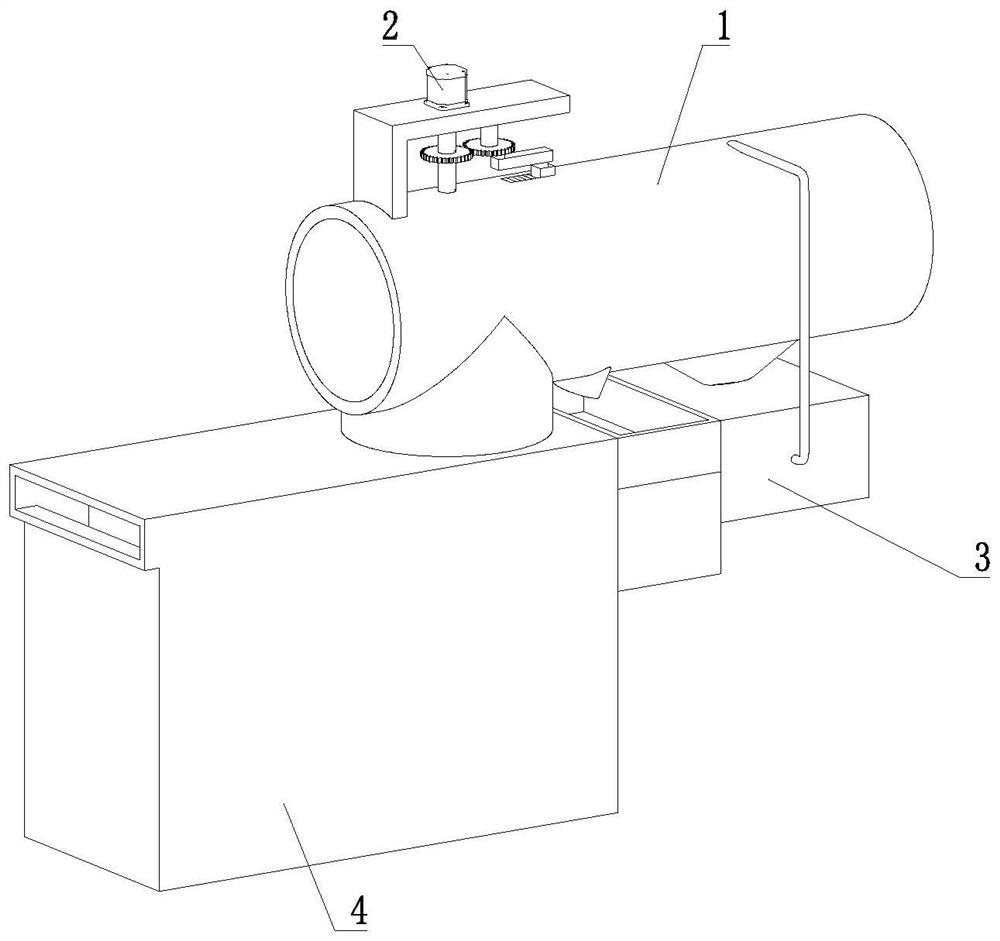

[0032] A flue gas denitration device for solid waste treatment proposed by the present invention includes an air intake assembly 1 and a denitration assembly 4;

[0033] like Figure 1-2 As shown, the denitration assembly 4 is provided with an air intake assembly 1, and the air intake assembly 1 is provided with a circulating dust removal assembly 3 for treating smoke and dust in the gas;

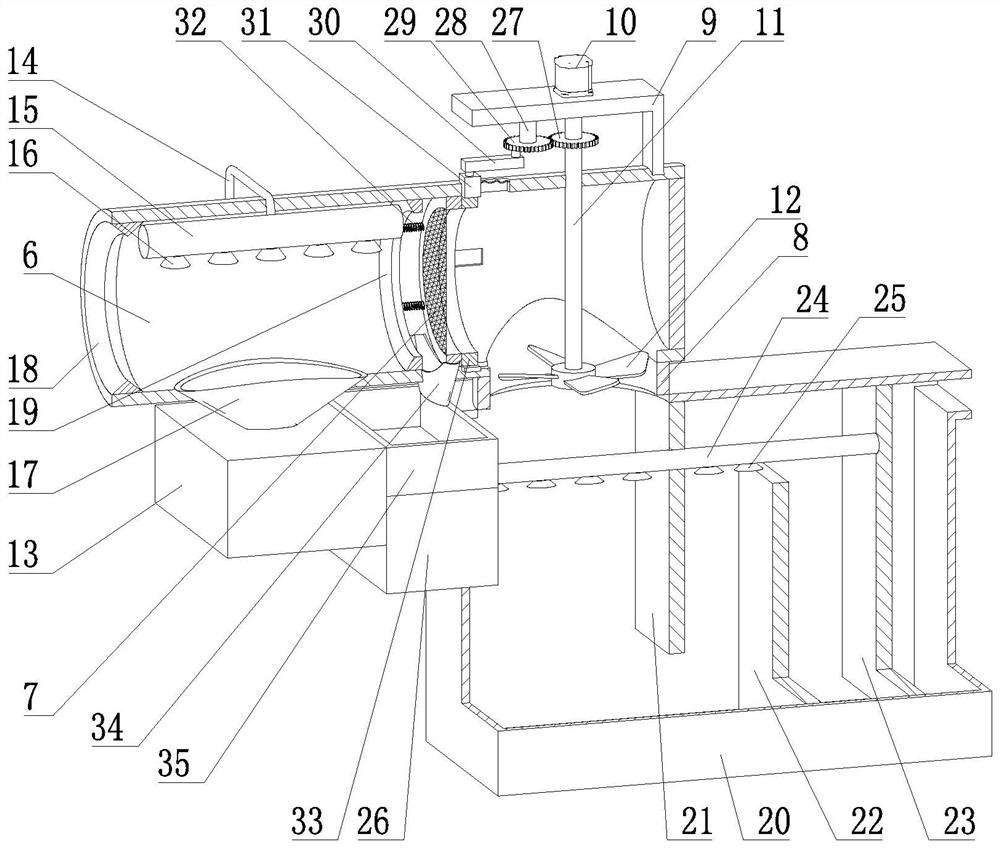

[0034] like image 3 As shown, the intake assembly 1 includes an intake pipe 6 and a connecting pipe 8; the intake pipe 6 is communicated with the denitration tank 20 through the connecting pipe 8, and the intake pipe 6 is provided with a filter screen 7; the intake pipe 6 is provided with a leak-proof ring A18 and the leak-proof ring B19, and the leak-proof ring A18 and the leak-proof ring B19 are respectively located on both sides of the dirt collecting hopper A17; the cross-section of the leak-proof ring A18 is an isosceles triangle, and the cross-sectional area of the leak-proof ring...

Embodiment 2

[0039] like Figure 1-3 As shown in the figure, a flue gas denitrification device for solid waste treatment proposed by the present invention, compared with the first embodiment, the difference in this embodiment is that the air intake assembly 1 is further provided with an automatic cleaning assembly 5, wherein the automatic cleaning assembly 5 It includes gear A27, rotating shaft B28, gear B29, reciprocating connecting rod 30, slider 31, movable ring 33, dirt collecting bucket B34, and dirt collecting box 35; The sliding block 31 is slidably arranged on the intake pipe 6, and the two ends of the reciprocating connecting rod 30 are respectively connected with the sliding block 31 and the gear B29 through the rotating column in rotation; The connection is not at the axis of the gear B29; the movable ring 33 is slidably arranged on the intake pipe 6 and connected with the slider 31; the intake pipe 6 is provided with a pleated sealing cloth, and the pleated sealing cloth is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap