Red mud-based catalyst for synthesizing low-carbon alcohol as well as preparation method and application of red mud-based catalyst

A catalyst and low-carbon alcohol technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of hydroxyl compounds. It can solve the problems of low selectivity and low utilization of C2+ alcohols, and achieve increased selectivity and improved utilization. The effect of high efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

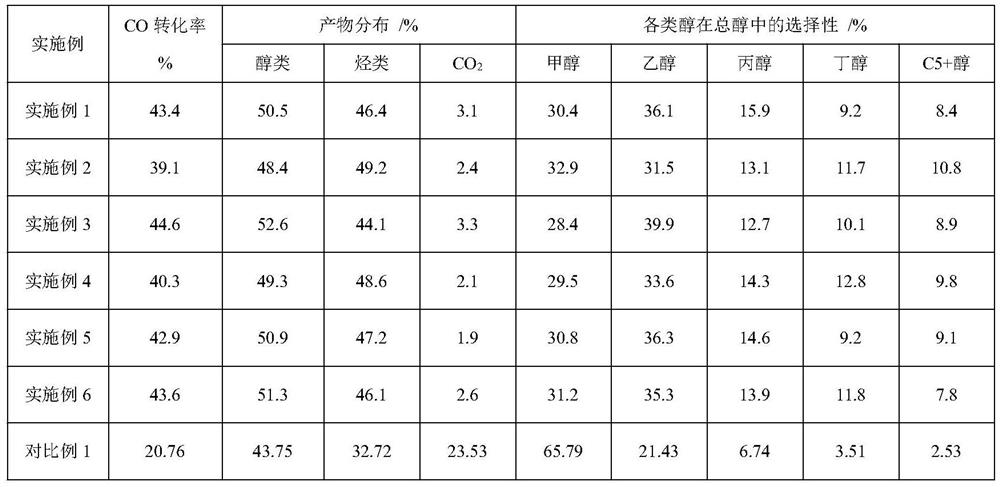

Examples

Embodiment 1

[0018] A red mud-based catalyst for synthesizing low-carbon alcohols, the preparation process is as follows:

[0019] 1) Preparation of catalyst carrier: soak the collected red mud in an ethanol solution (volume concentration of 95%, the same below), ultrasonically treat for 2h, then wash with distilled water for 5 times to neutrality, filter and dry to obtain the treated red mud vector. The mass ratio of red mud to ethanol solution is 1:4.

[0020] 2) Preparation of catalyst by impregnation: according to the molar ratio of Cu:Mo:Zr:Ce=1:0.3:0.064:0.072, the nitrates and ammonium molybdate of copper, zirconium and cerium are dissolved in water to prepare a mixed solution. Under vacuum conditions, impregnate 1 g of the red mud carrier obtained in step 1) with the above mixed solution, then suction filtration, and then dry the impregnated catalyst precursor at 100° C. and calcinate at 450° C. to obtain a low-carbon alcohol for synthesizing. 2.5g of red mud-based catalyst, in w...

Embodiment 2

[0024] A red mud-based catalyst for synthesizing low-carbon alcohols, the preparation process is as follows:

[0025] 1) Preparation of catalyst carrier: soak the collected red mud in an ethanol solution, ultrasonically treat it at 50° C. for 2 hours, then wash it with distilled water for 6 times until neutral, suction filter and dry to obtain the treated red mud carrier. The mass ratio of red mud to ethanol solution is 1:4.

[0026] 2) Preparation of catalyst by impregnation: according to the molar ratio of Cu:Co:Cr:Ce=1:0.2:0.055:0.064, the nitrates of copper, cobalt, chromium and cerium are dissolved in water to prepare a mixed solution. Under vacuum conditions, impregnate 1 g of the red mud carrier obtained in step 1) with the above mixed solution, then suction filtration, and then dry the impregnated catalyst precursor at 100 ° C and calcinate at 400 ° C to obtain a low-carbon alcohol for synthesis. 2g of red mud-based catalyst, in which the red mud carrier accounts for ...

Embodiment 3

[0029] The reaction of preparing the catalyst carrier, impregnating the catalyst for preparing the catalyst and synthesizing the lower alcohol is the same as that in Example 1, except that the molar ratio of the metal elements used is Cu:Mo:Zr:La=1:0.3:0.055:0.064.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com