Composite carbon material as well as preparation method and application thereof

A composite carbon and carbon substrate technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of thermal expansion coefficient mismatch, silicon carbide coating easy to decompose, coating easy to fall off, etc. To achieve the effect of increasing life, avoiding peeling failure, and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

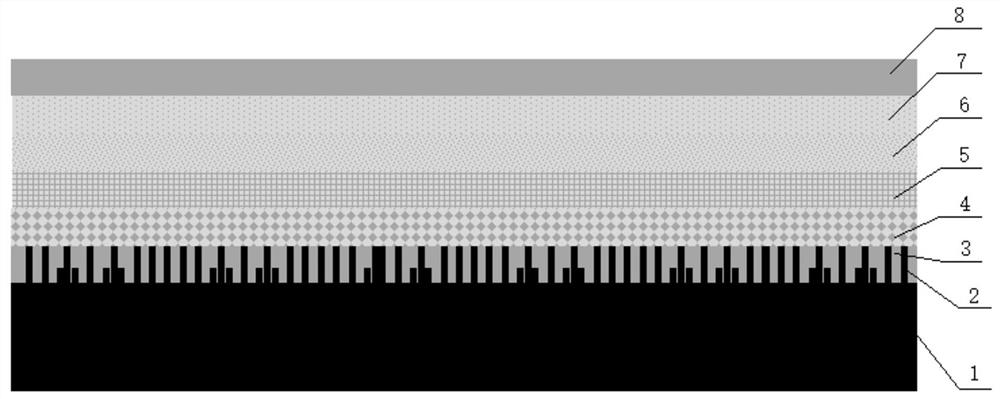

[0038] like figure 1 As shown, the composite carbon material in this embodiment includes a carbon substrate and a composite coating disposed on the surface of the carbon substrate, and the carbon substrate is selected with a density of 1.8 g / cm 3 , a graphite substrate 1 with a graphite purity of 5 ppm, and the composite coating sequentially includes a silicon carbide composite layer, a first silicon carbide-tantalum carbide composite layer 4, a second silicon carbide-tantalum carbide composite layer 5, and a third silicon carbide-tantalum carbide composite layer from inside to outside. The silicon-tantalum carbide composite layer 6, the fourth silicon carbide-tantalum carbide composite layer 7 and the tantalum carbide layer 8; wherein, the silicon carbide composite layer includes the silicon carbide layer 3 and the carbides dispersed in the silicon carbide layer 3 and the graphite substrate 1 Silicon nanowires 2, the silicon carbide nanowires 2 protrude into the graphite subs...

Embodiment 2

[0051] The composite carbon material in this embodiment includes a carbon substrate and a composite coating disposed on the surface of the carbon substrate, and the carbon substrate is selected with a density of 1.8 g / cm 3 , a graphite substrate 1 with a graphite purity of 5 ppm, and the composite coating sequentially includes a silicon carbide composite layer, a first silicon carbide-tantalum carbide composite layer 4, a second silicon carbide-tantalum carbide composite layer 5, and a third silicon carbide-tantalum carbide composite layer from inside to outside. The silicon-tantalum carbide composite layer 6, the fourth silicon carbide-tantalum carbide composite layer 7 and the tantalum carbide layer 8; wherein, the silicon carbide composite layer includes the silicon carbide layer 3 and the carbides dispersed in the silicon carbide layer 3 and the graphite substrate 1 Silicon nanowires 2, the silicon carbide nanowires 2 extend into the graphite substrate 1 and the silicon car...

Embodiment 3

[0064] The composite carbon material in this embodiment includes a carbon substrate and a composite coating disposed on the surface of the carbon substrate, and the carbon substrate is selected with a density of 1.8 g / cm 3 , a graphite substrate 1 with a graphite purity of 5 ppm, and the composite coating sequentially includes a silicon carbide composite layer, a first silicon carbide-tantalum carbide composite layer 4, a second silicon carbide-tantalum carbide composite layer 5, and a third silicon carbide-tantalum carbide composite layer from inside to outside. The silicon-tantalum carbide composite layer 6, the fourth silicon carbide-tantalum carbide composite layer 7 and the tantalum carbide layer 8; wherein, the silicon carbide composite layer includes the silicon carbide layer 3 and the carbides dispersed in the silicon carbide layer 3 and the graphite substrate 1 Silicon nanowires 2, the silicon carbide nanowires 2 protrude into the graphite substrate 1 and the silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com