Mining emulsion explosive with high sulfur content and production process method thereof

An emulsion explosive and high-sulfur technology is applied in the formulation and preparation field of emulsion explosives, which can solve the problems of inability to detonate, the quality of explosives and the unqualified crystallization point, so as to eliminate negative effects, prolong operation time, and solve work stoppages. Adjusting the effect of detected bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

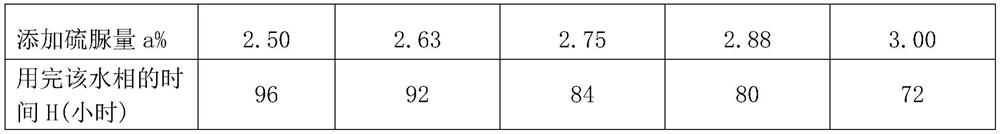

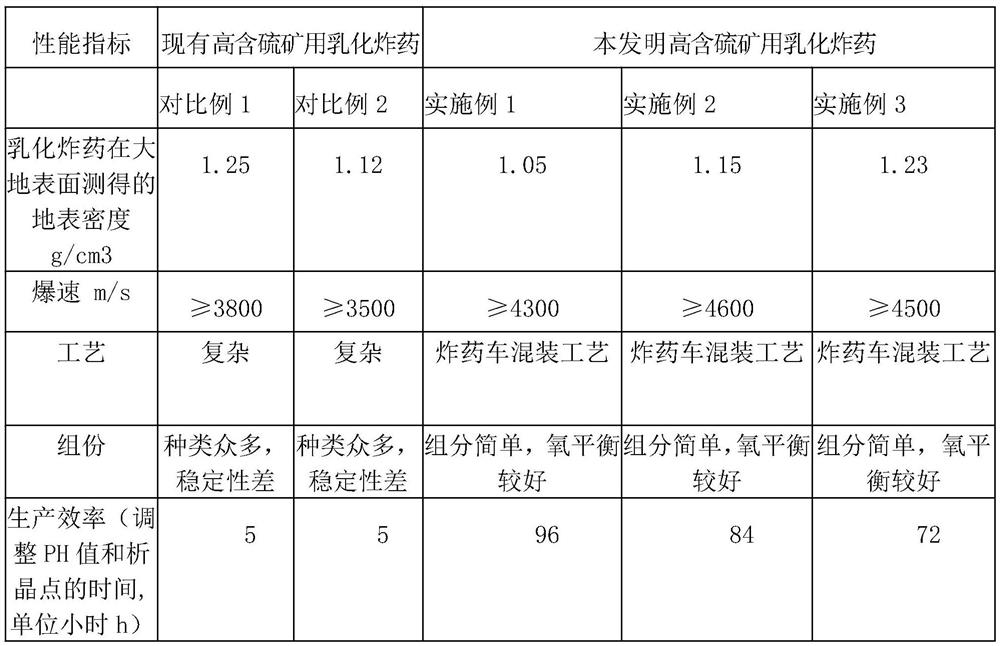

[0033] A kind of high-sulfur-containing emulsion explosive for mines provided by this embodiment, including

[0034] Water phase components: 73% by weight of ammonium nitrate, 2.50% by weight of thiourea, 0.030% by weight of nitric acid;

[0035] Oil phase components: 2.50% by weight of diesel oil, 1.50% by weight of motor oil, 1.00% by weight of emulsifier, in this example, the emulsifier is Span-80, namely sorbitan oleate; the kinematic viscosity of the motor oil 10.5mm at 100°C 2 / s, flash point (opening) not lower than 160 ℃, no water-soluble acid and alkali;

[0036] Sensitizing component: 0.010% by weight of sodium nitrite;

[0037] The rest is water. The parts by weight of all components including water add up to 100%.

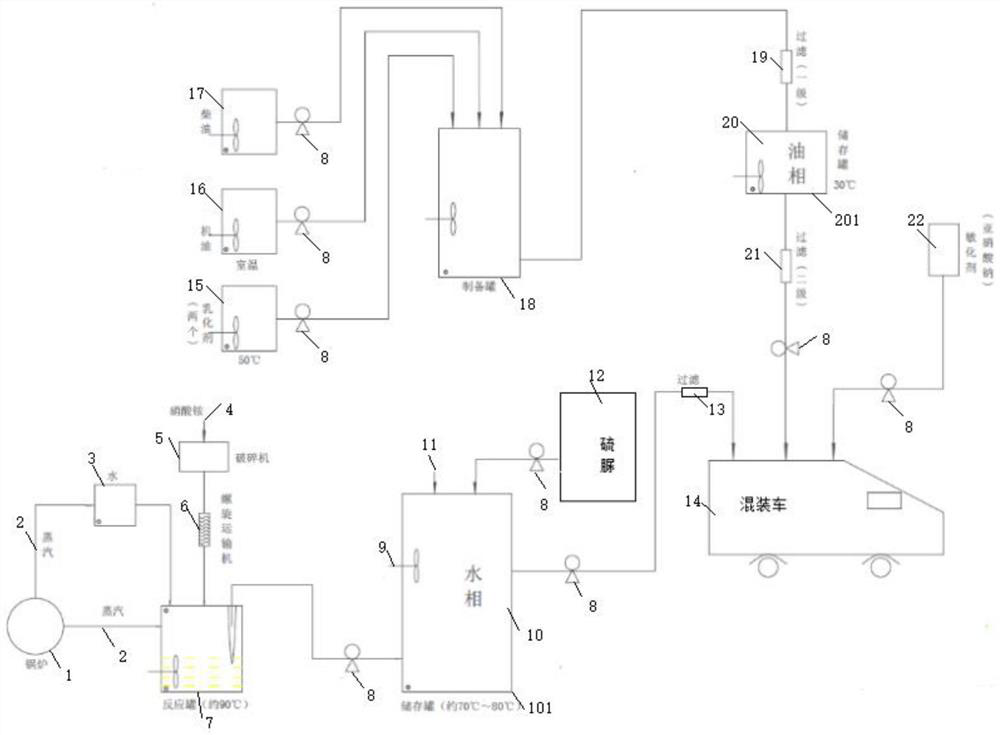

[0038] like figure 1 , also provides the production process method of the high-sulfur mine emulsion explosive of the formula of the present embodiment, comprising the following steps:

[0039] Preparation of aqueous solution: firstly crush ammoniu...

Embodiment 2

[0063] A kind of high-sulfur-containing emulsion explosive for mines provided by this embodiment, including

[0064] Water phase components: 74% by weight of ammonium nitrate, 2.73% by weight of thiourea, 0.033% by weight of nitric acid;

[0065] Oil phase components: 2.77% by weight of diesel oil, 1.85% by weight of motor oil, 1.38% by weight of emulsifier, in this example, the emulsifier is Span-80, namely sorbitan oleate; the kinematic viscosity of the motor oil 12.5mm at 100°C 2 / s, flash point (opening) not lower than 160 ℃, no water-soluble acid and alkali;

[0066] Sensitizing component: 0.0125% by weight of sodium nitrite;

[0067] The rest is water. The parts by weight of all components including water add up to 100%.

[0068] like figure 1 , also provides the production process method of the high-sulfur mine emulsion explosive of the formula of the present embodiment, comprising the following steps:

[0069] Preparation of aqueous solution: firstly crush ammoni...

Embodiment 3

[0088] A kind of high-sulfur-containing emulsion explosive for mines provided by this embodiment, including

[0089] Water phase components: 75% by weight of ammonium nitrate, 3.00% by weight of thiourea, 0.035% by weight of nitric acid;

[0090] Oil phase components: 3.00% by weight of diesel oil, 2.00% by weight of motor oil, 1.50% by weight of emulsifier, in this embodiment, the emulsifier is Span-80, namely sorbitan oleate; the kinematic viscosity of the motor oil 14.5mm at 100°C 2 / s, flash point (opening) not lower than 160 ℃, no water-soluble acid and alkali;

[0091] Sensitizing component: 0.015% by weight of sodium nitrite;

[0092] The rest is water. The parts by weight of all components including water add up to 100%.

[0093] like figure 1, also provides the production process method of the high-sulfur mine emulsion explosive of the formula of the present embodiment, comprising the following steps:

[0094] Preparation of aqueous solution: firstly crush ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com