Preparation method of Mxene-based conductive, wave-absorbing and anti-corrosion integrated coating

A kind of coating and integrated technology, applied in the direction of conductive coatings, anti-corrosion coatings, radiation-absorbing coatings, etc., can solve the problems of structural change, mechanical, electrochemical and other performance degradation, and obstacles to the development and application of MXenes, so as to achieve the improvement of wave-absorbing performance, Excellent absorbing performance, preventing secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

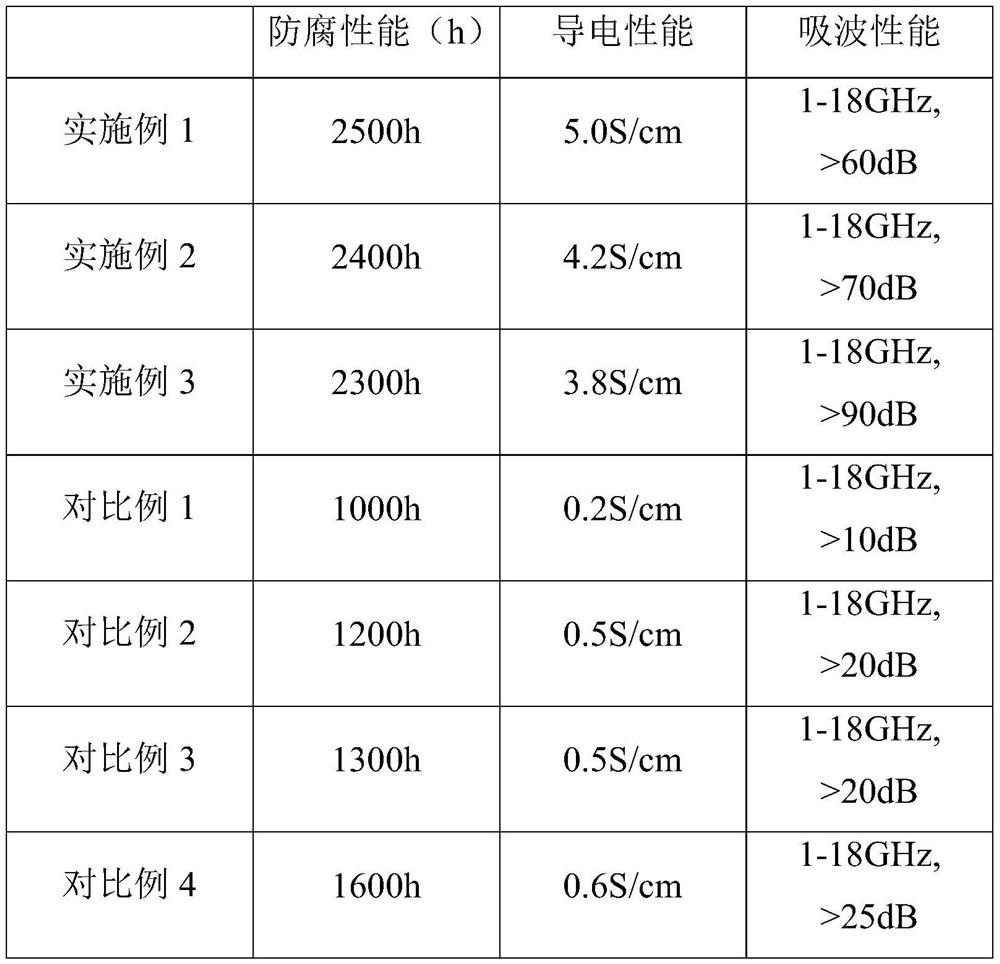

Examples

Embodiment 1

[0030] (1) Preparation of GNS@magnetic fillers

[0031] a. Amino functionalization on the surface of magnetic fillers

[0032] 2 parts of N-(β-aminoethyl)-γ-aminopropylmethyl-dimethoxysilane was added to 20 parts of a mixed solvent of ethanol and water, where the ratio of ethanol and water was 95:5 , adjust the pH of the solution to 10, and then add it into the powder of the ferromagnetic filler in the form of spray, and continue to stir at 80 °C for 30 min to obtain the magnetic filler with amino groups on the surface.

[0033] b. Disperse 2 parts of graphene in 20 parts of water, add 1 part of polyvinylpyrrolidone surfactant, adjust the pH to 10, then add 8 parts of magnetic material with amino groups on the surface, stir at high speed for 30min, and then emulsify with an emulsifying pump 60min, dried to obtain a mixture of GNS@magnetic filler;

[0034] (2) Preparation of GNS / Mxene / magnetic filler composites

[0035] Add 10 parts of graphene, 10 parts of Mxene, and 40 par...

Embodiment 2

[0039] (1) Preparation of GNS@magnetic fillers

[0040] a. Amino functionalization on the surface of magnetic fillers

[0041] 5 parts of N-(β-aminoethyl)-γ-aminopropylmethyl-dimethoxysilane was added to 50 parts of a mixed solvent of ethanol and water, and the ratio of ethanol and water was 95:5 , adjust the pH of the solution to 10, and then add it into the powder of the ferromagnetic filler in the form of spray, and continue to stir at 80 °C for 30 min to obtain the magnetic filler with amino groups on the surface.

[0042] b. Disperse 5 parts of graphene in 50 parts of water, add 3 parts of OP-10 surfactant, adjust the pH to 10, then add 30 parts of magnetic material with amino groups on the surface, stir at high speed for 30 minutes, and then use an emulsification pump to emulsify 60min, dried to obtain a mixture of GNS@magnetic filler;

[0043] (2) Preparation of GNS / Mxene / magnetic filler composites

[0044] Add 10 parts of graphene, 10 parts of Mxene, and 60 parts of...

Embodiment 3

[0048] (1) Preparation of GNS@magnetic fillers

[0049] a. Amino functionalization on the surface of magnetic fillers

[0050]10 parts of N-(β-aminoethyl)-γ-aminopropylmethyl-dimethoxysilane was added to 100 parts of a mixed solvent of ethanol and water, and the ratio of ethanol and water was 95:5 , adjust the pH of the solution to 10, then add it into the powder of ferromagnetic filler in the form of spray, and continue stirring at 80 °C for 30 min to obtain the magnetic filler with amino groups on the surface.

[0051] b. Disperse 10 parts of graphene in 100 parts of water, add 5 parts of OP-100 surfactant, adjust the pH to 10, then add 100 parts of magnetic material with amino groups on the surface, stir at high speed for 30 minutes, and then emulsify with an emulsification pump 60min, dry to obtain a mixture of GNS@magnetic filler;

[0052] (2) Preparation of GNS / Mxene / magnetic filler composites

[0053] Add 10 parts of graphene, 10 parts of Mxene, and 100 parts of magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com