Edge polishing method of metal film material, metal film material and application

A metal film and edge technology, applied in the field of medical devices, can solve problems such as soft tissue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Seal a layer of polypropylene polymer film coat with a thickness of 0.05mm on the surface of the zinc film material by heat sealing and curing method, and expose the edge of the zinc film material.

[0062] (2) The zinc film material after sealing is placed on the anode of the electrochemical polishing equipment, and the cathode is connected to platinum-iridium wire insoluble metals, and polished according to the following polishing parameters. The current is direct current. The current range is 1A, the voltage range is 30V, the single action time is 300s, and the polishing times are 2 times. The electrolyte used is a mixed polishing solution with a volume ratio of propanol: ethylene glycol: phosphoric acid = 50:48:2.

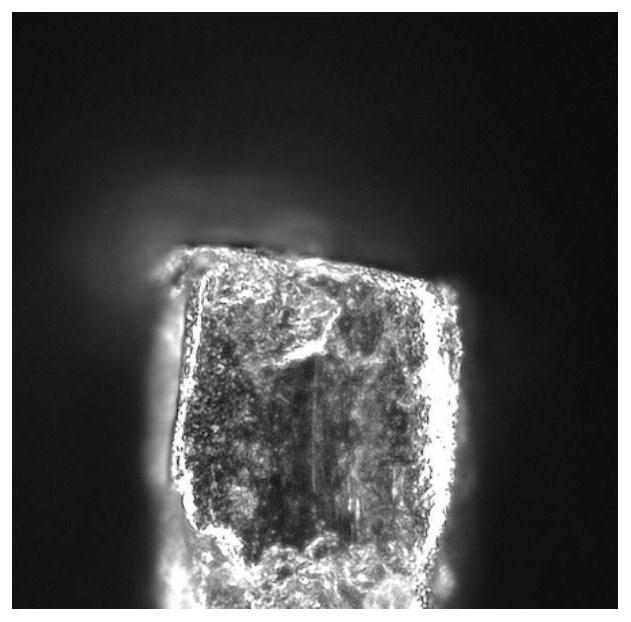

[0063] (3) After polishing, the product peels off the polymer film coating. As for ultrasonic cleaning in absolute ethanol, the zinc film material after the edge is sharpened can be obtained. The boundary morphology of the zinc film material and th...

Embodiment 2

[0065] (1) A layer of 0.2mm-thick polytetrafluoroethylene polymer film coating is sealed on the surface of the magnesium film material by light curing, and the edge of the magnesium film material is exposed.

[0066] (2) Place the closed magnesium film material on the anode of the electrochemical polishing equipment, connect the cathode with platinum-iridium insoluble metals, and polish according to the following polishing parameters. The current is direct current. The current range is 0.2A, the voltage range is 10V, the single action time is 20s, and the polishing times are 6 times. The electrolyte used is a mixed polishing solution with a volume ratio of ethanol:glycerol:acetic acid=55:40:5.

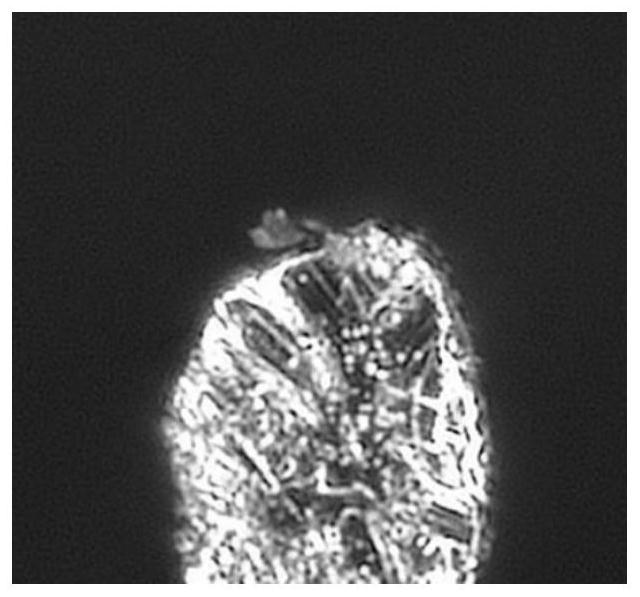

[0067] (3) After polishing, the product peels off the polymer film coating, and ultrasonic cleaning in absolute ethanol can obtain the magnesium film material after the edge is sharpened. The boundary morphology of the magnesium film material and the magnesium film material after edg...

Embodiment 3

[0069] (1) Seal a layer of 0.1mm thick polymethyl methacrylate polymer film coating on the surface of the iron film material by heat-sealing and curing method, and expose the edge of the iron film material.

[0070] (2) The iron film material after sealing is placed on the anode of the electrochemical polishing equipment, and the cathode is connected to platinum-iridium wire insoluble metals, and polished according to the following polishing parameters. The current is direct current. The current range is 2A, the voltage range is 60V, the single action time is 200s, and the polishing times are 5 times. The electrolyte used is a mixed polishing liquid with a volume ratio of amyl alcohol: ethylene glycol: carbonic acid = 30:60:10.

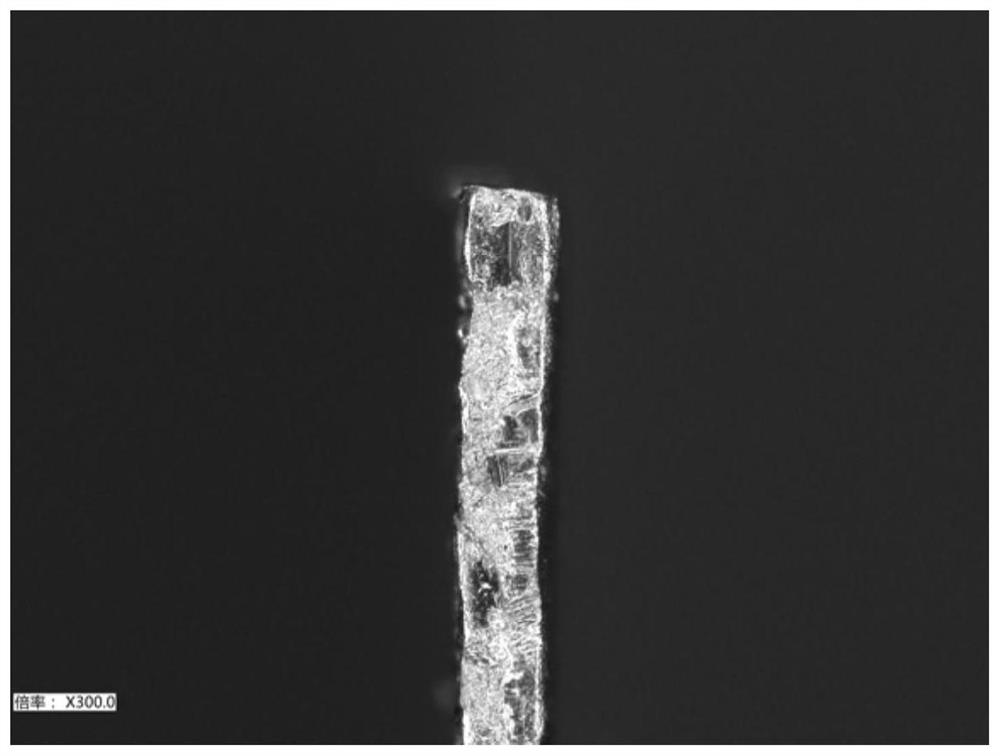

[0071] (3) After polishing, the product peels off the polymer film coating. As for ultrasonic cleaning in absolute ethanol, the iron film material after the edge is sharpened can be obtained. The boundary morphology of the iron film material and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com