Outdoor mat and preparation process thereof

A preparation process and outdoor technology, which is applied in the field of outdoor mats, can solve the problems that Oxford cloth mats cannot be used normally, the moisture-proof function is weakened, and the moisture-proof effect is not good, so as to achieve excellent waterproof and moisture-proof effects, improve water resistance, and excellent antibacterial effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

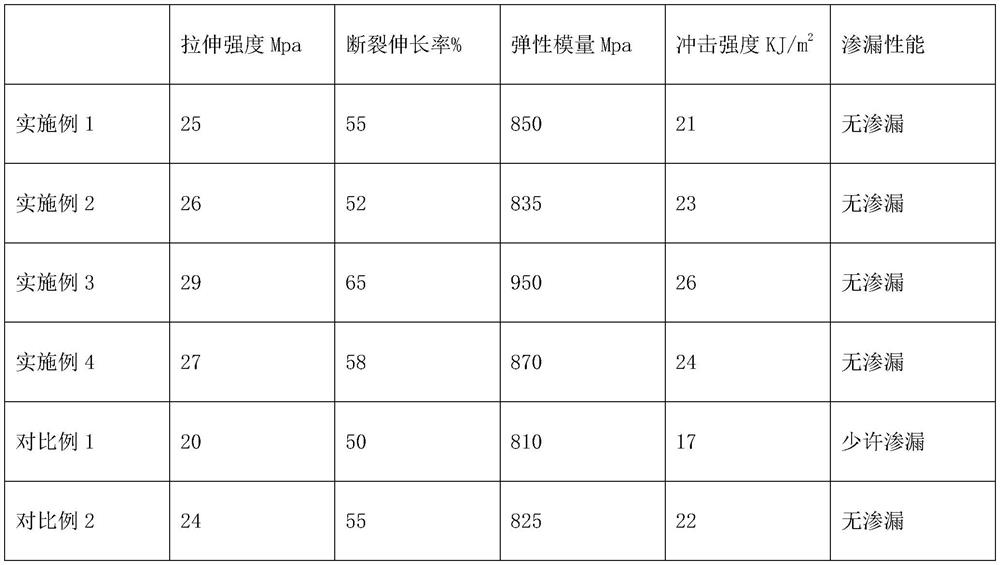

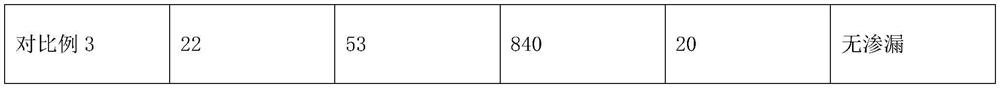

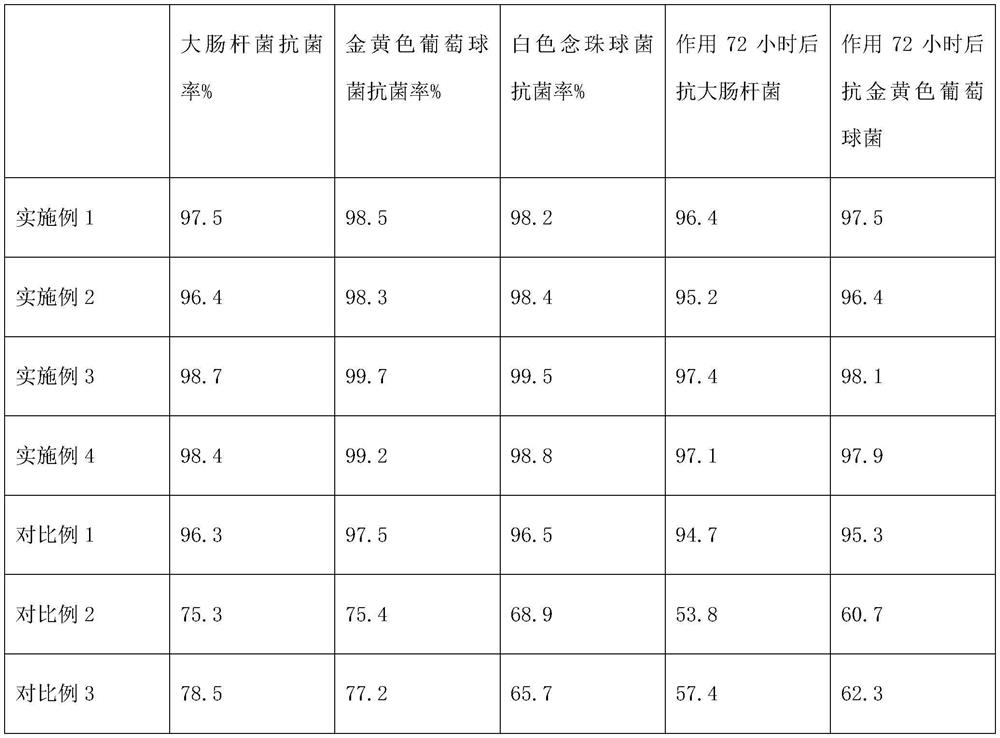

Examples

Embodiment 1

[0031] An outdoor pad is formed by coating a base paper with a coating material, and the coating material includes the following components in parts by weight: 54 parts of LLDPE, 35 parts of bio-based polybutylene succinate, and 7 parts of EVA , 12 parts of phenolic resin, 2.4 parts of stone pine powder, and 6.75 parts of graphene oxide.

[0032] Said lycopodium powder is prepared by the following method: air-drying the whole plant of lycium pine, soaking in olive oil for 5 days, drying and pulverizing into 300-mesh powder.

[0033] The preparation technology of above-mentioned embodiment 1 outdoor mat, comprises the steps:

[0034] S1, adding the coating material of Example 1 into the high-speed mixer, stirring at 250°C for 20 minutes, mixing evenly, and maintaining 150°C to make the coating material a molten material;

[0035] S2, the molten material is transported to the extrusion die to be extruded and coated on the transported base paper to form a coating layer;

[0036...

Embodiment 2

[0038] An outdoor mat is formed by coating a base paper with a coating material, and the coating material includes the following components in parts by weight: 40 parts of LLDPE, 50 parts of bio-based polybutylene succinate, and 3 parts of EVA , 18 parts of phenolic resin, 6 parts of stone pine powder, and 4 parts of graphene oxide.

[0039] Said lycopodium powder is prepared by the following method: air-drying the whole plant of lycium pine, soaking in olive oil for 3 days, drying and pulverizing into 400-mesh powder.

[0040] The preparation technology of above-mentioned embodiment 2 outdoor mat, comprises the steps:

[0041] S1, add the coating material of Example 2 into the high-speed mixer, stir at 150°C for 30 minutes, mix evenly, and keep the coating material at 250°C to make the coating material a molten material;

[0042] S2, the molten material is transported to the extrusion die to be extruded and coated on the transported base paper to form a coating layer;

[0043...

Embodiment 3

[0045] An outdoor pad is formed by coating a base paper with a coating material, and the coating material includes the following components in parts by weight: 45 parts of LLDPE, 45 parts of bio-based polybutylene succinate, and 5 parts of EVA , 16 parts of phenolic resin, 4 parts of stone pine powder, and 5 parts of graphene oxide.

[0046] The lycopodium powder is prepared by the following method: air-drying the whole plant of lycopodium pine, soaking in olive oil for 4 days, then drying and pulverizing it into powder of 350 meshes.

[0047] The preparation technology of above-mentioned embodiment 3 outdoor mat, comprises the steps:

[0048] S1, add the coating material of Example 3 into the high-speed mixer, stir at 200°C for 25min, mix evenly, and keep the coating material at 200°C to make the coating material a molten material;

[0049] S2, the molten material is transported to the extrusion die to be extruded and coated on the transported base paper to form a coating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com