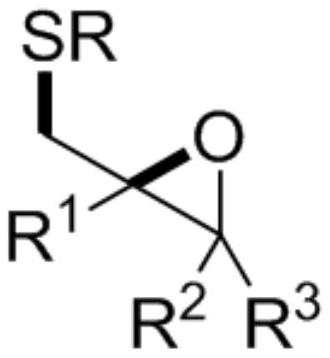

Method for preparing 3-((aryl sulfydryl/alkyl sulfydryl) methyl) ethylene oxide

A technology of ethylene oxide and aryl mercapto group, applied in the field of preparing 3-methyl) ethylene oxide, can solve problems such as harsh reaction conditions, and achieve the effects of easy separation and purification, simple operation method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 2,2-dimethyl-3-phenyl-3-((phenylthio)methyl)oxirane

[0022] 2,2-Dimethyl-3-((phenylthio)methyl)oxirane

[0023]

[0024] Combine 2-methyl-3-phenyl-3-en-2-ol (0.2 mmol, 32.42 mg), 1-(phenylthio)succinimide (0.4 mmol, 82.81 mg) and HFIP (2.0 mL) ) into a 20 mL Schlenk tube fitted with a Teflon cap. Then, the Schlenk tube was reacted at room temperature for 2.5 hours. After that, it was concentrated under reduced pressure. The residue was purified by flash chromatography on silica gel (PE / EA20 / 1) to give the desired product in 91% yield. NMR data: 1 H NMR (CDCl 3 ,400MHz):δ7.38–7.36(m,2H),7.33–7.28(m,3H),7.25–7.24(m,2H,overlapped with CDCl 3 ), 7.21–7.18 (m, 2H), 7.14–7.11 (m, 1H), 3.55 (d, J=13.0Hz, 1H), 3.40 (d, J=13.0Hz, 1H), 1.51 (s, 3H) ,1.00(s,3H). 13 C NMR (CDCl 3 , 101MHz): δ138.7, 136.6, 129.4, 128.6, 127.8, 127.3, 126.9, 125.9, 68.1, 64.6, 40.5, 22.1, 20.6. MS data: MS(EI): 271.1 (M + ).

Embodiment 22

[0025] Example 22, 2-dimethyl-3-((phenylthio)methyl)-3-(p-tolyl)oxirane

[0026] 2,2-Dimethyl-3-((phenylthio)methyl)-3-(p-toly)oxirane

[0027]

[0028]2-Methyl-3-p-tolyl-3-en-2-ol (0.2 mmol, 35.22 mg), 1-(phenylthio)succinimide (0.26 mmol, 53.82 mg) and HFIP (2.0 mL) into a 20 mL Schlenk tube fitted with a Teflon cap. Then, the Schlenk tube was reacted at room temperature for 2.5 hours. After that, it was concentrated under reduced pressure. The residue was purified by flash chromatography on silica gel (PE / EA20 / 1) to give the desired product in 56% yield. NMR data: 1 H NMR (CDCl 3 400MHz): δ7.25–7.24 (m, 4H, overlapped with CDCl 3 ), 7.21–7.17 (m, 2H), 7.12–7.10 (m, 3H), 3.53 (d, J=12.9Hz, 1H), 3.37 (d, J=12.8Hz, 1H), 2.32 (s, 3H) ,1.49(s,3H),1.00(s,3H). 13 C NMR (101MHz, CDCl 3 ): δ137.0, 136.7, 135.8, 129.5, 128.7, 128.6, 126.9, 126.0, 68.1, 64.7, 40.7, 22.2, 21.2, 20.7. MS data: MS(EI): 285.1 (M + ).

Embodiment 3

[0029] Example 3: 2,2-Dimethyl-3-((phenylthio)methyl)-3-(p-tert-butylphenyl)oxirane

[0030] 2-(4-(Tert-butyl)phenyl)-3,3-dimethyl-2-((phenythio)methyl)oxirane

[0031]

[0032] 2-Methyl-3-p-tert-butylphenyl-3-en-2-ol (0.2 mmol, 32.42 mg), 1-(phenylthio)succinimide (0.26 mmol, 53.82 mg) and HFIP (2.0 mL) was added to a 20 mL Schlenk tube fitted with a Teflon cap. Then, the Schlenk tube was reacted at room temperature for 2.5 hours. After that, it was concentrated under reduced pressure. The residue was purified by flash chromatography on silica gel (PE / EA20 / 1) to give the desired product in 59% yield. NMR data: 1 H NMR (CDCl 3 ,400MHz):δ7.34-7.28(m,4H),7.24-7.22(m,2H),7.20-7.16(m,2H),7.14-7.09(m,1H),3.53(d,J=12.9Hz ,1H),3.41(d,J=12.9Hz,1H),1.52(s,3H),1.32(s,9H),1.03(s,3H). 13 C NMR (CDCl 3 , 101MHz): δ150.1, 136.8, 135.7, 129.5, 128.6, 126.7, 125.9, 124.8, 68.1, 64.8, 40.7, 34.5, 31.3, 22.3, 20.8. MS data: MS(EI): 327.1 (M + ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com