Preparation method of novel high-dispersity and high-slump-retaining polycarboxylate superplasticizer

A high-dispersion, polycarboxylic acid technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of poor slump retention, inability to simultaneously improve initial water reduction rate and slump retention, Extend the slump retention and other issues to achieve the effect of raising the upper limit of performance, increasing product competitiveness, and improving initial water reduction and slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

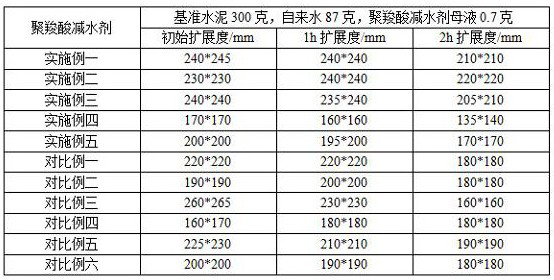

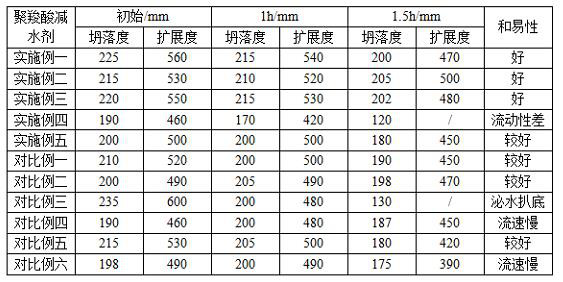

Examples

Embodiment 1

[0029] A preparation method of a novel polycarboxylate water-reducing agent with high dispersibility and high slump retention, specifically comprising the following steps:

[0030] Step 1. Preparation of base solution: add 500 parts of water into the reaction kettle, add 360 parts of diethylene glycol monovinyl polyoxyethylene ether with a molecular weight of 3000, and stir until completely dissolved to obtain diethylene glycol monovinyl polyoxyethylene. Oxyethylene ether aqueous solution, let stand for 30min, after defoaming, add 3 parts of diethylene glycol divinyl ether;

[0031] Step 2: Additive preparation: add 50 parts of water into a stirring tank, then add 30 parts of acrylic acid, stir evenly and store in the dripping tank A to obtain the dripping liquid A, and then add 50 parts of water to another stirring tank. In the tank, add 0.3 part of vitamin, stir evenly, and store in the dripping tank B to obtain the dripping solution B;

[0032] Step 3, dropwise reaction: a...

Embodiment 2

[0035] A preparation method of a novel polycarboxylate water-reducing agent with high dispersibility and high slump retention, specifically comprising the following steps:

[0036] Step 1. Preparation of base solution: add 400 parts of water into the reaction kettle, add 360 parts of 4-hydroxybutyl vinyl polyethylene glycol polyoxyethylene ether with a molecular weight of 4000, and stir until completely dissolved to obtain 4-hydroxybutyrin After the aqueous solution of vinyl polyethylene glycol polyoxyethylene ether, let stand for 30 minutes, and after defoaming is completed, add 5 parts of diethylene glycol divinyl ether;

[0037] Step 2. Additive preparation: add 50 parts of water into a stirring tank, then add 26 parts of acrylic acid, stir evenly and store in the dripping tank A to obtain the dripping liquid A, then add 50 parts of water to another stirring tank. In the tank, add 0.4 part of vitamin C, stir evenly and store in the dripping tank B to obtain dripping liquid ...

Embodiment 3

[0041] A preparation method of a novel polycarboxylate water-reducing agent with high dispersibility and high slump retention, specifically comprising the following steps:

[0042] Step 1, base liquid preparation: add 400 parts of water into the reaction kettle, add 360 parts of diethylene glycol monovinyl polyoxyethylene ether with a molecular weight of 3000, and stir until completely dissolved to obtain diethylene glycol monovinyl polyoxyethylene After the vinyl ether aqueous solution, let stand for 30min, after the defoaming is completed, add 3 parts of 4-hydroxybutyl divinyl ether;

[0043] Step 2. Additive preparation: add 20 parts of water into a stirring tank, then add 30 parts of acrylic acid, stir evenly and store in the dripping tank A to obtain the dripping liquid A, and then add 50 parts of water to another stirring tank. In the tank, add 0.4 part of vitamin C, stir evenly and store in the dripping tank B to obtain dripping liquid B;

[0044]Step 3, dropwise react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com