Device and method for preparing ammonium bicarbonate by using carbon dioxide waste gas and nitrate wastewater

A technology of carbon dioxide and ammonium bicarbonate, applied in the direction of ammonium carbonate/acid carbonate, chemical instruments and methods, separation methods, etc., can solve problems such as environmental pollution, reduce energy consumption, improve activity, and accelerate The effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

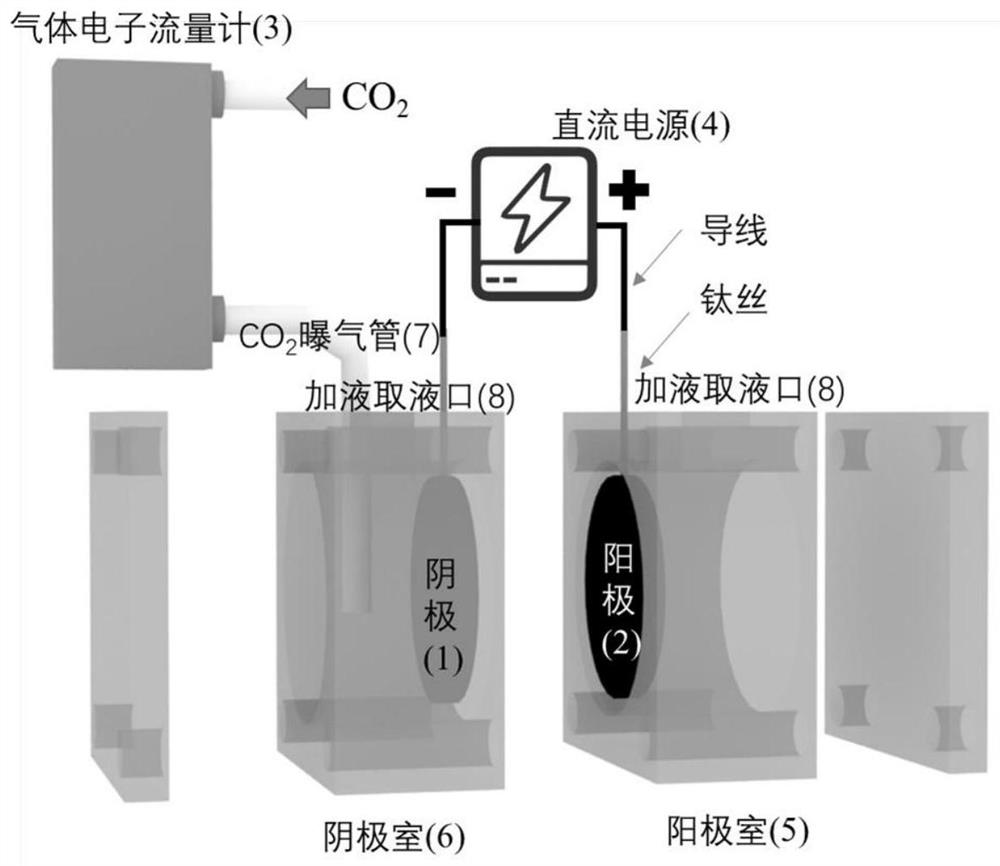

[0038] The present invention proposes a device for preparing ammonium bicarbonate by utilizing carbon dioxide waste gas and nitrate waste water. According to the embodiments of the present invention, refer to figure 1 It is a schematic diagram of the device of the present invention, comprising a cobalt oxide / foamed copper cathode (1); a dimensionally stable anode (2); a gas electronic flowmeter (3); a DC power supply (4); an anode chamber (5); Cathode compartment (6); CO 2 The aeration pipe (7) is inserted into the cathode chamber (6), close to the cathode (1), and the tops of the cathode and anode are provided with liquid additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com