Antibacterial ES fiber for cool-feeling non-woven fabric and preparation method of antibacterial ES fiber

A non-woven fabric and fiber technology, applied in the fiber field, can solve the problems of ES fiber's weak antibacterial properties, inability to meet production requirements in different fields, and sultry products, and achieve the effects of good dispersion, excellent thermal conductivity, and not easy to agglomerate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

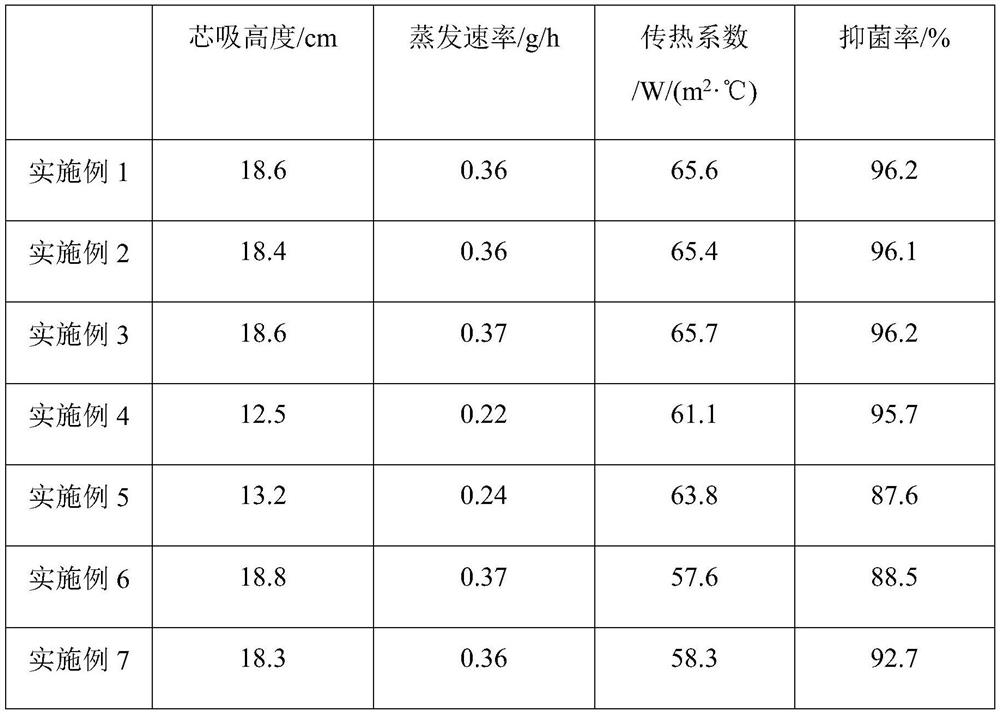

Examples

Embodiment 1

[0024] Step 1: Preparation of boron nitride grafted with Schiff base:

[0025] Preparation of Schiff base: take 12mmol of 2-hydroxyacetophenone, add dropwise 35ml of anhydrous methanol, 12mmol of 2-hydroxypropylamine, react at 77°C for 6h, cool for crystallization, filter, add 10ml of dimethylformamide, 10ml of anhydrous Methanol, cooling and crystallization, filtration, and drying to obtain Schiff base.

[0026] 10g of boron nitride was heated at 1000℃ for 2.5h, cooled to 26℃, washed with deionized water, filtered and dried to obtain hydroxylated nano-boron nitride; 1g of Schiff base was added, 20ml of deionized water was added, and at 45 The reaction was carried out at ℃ for 1.5 h to obtain boron nitride grafted with Schiff base.

[0027] Step 2: Preparation of L-arginine-grafted ZnO-MOFs:

[0028] Preparation of ZnO-MOFs: take 15g of zinc nitrate hexahydrate and 1000ml of deionized water, stir evenly to obtain a solution of zinc nitrate hexahydrate; take 8.2g of 2-methyli...

Embodiment 2

[0037] Step 1: Preparation of boron nitride grafted with Schiff base:

[0038] Preparation of Schiff base: take 12mmol of 2-hydroxyacetophenone, add dropwise 35ml of anhydrous methanol and 12mmol of 2-hydroxypropylamine, react at 75°C for 5.5h, cool for crystallization, filter, add 10ml of dimethylformamide, 10ml of Water methanol, cooling and crystallization, filtration and drying to obtain Schiff base.

[0039] 10g of boron nitride was heated at 980°C for 2h, cooled to 25°C, washed with deionized water, filtered and dried to obtain hydroxylated nanoboron nitride; 1g of Schiff base was added, 20ml of deionized water was added, and the temperature was 40°C. The reaction was continued for 1 h to obtain boron nitride grafted with Schiff base.

[0040] Step 2: Preparation of L-arginine-grafted ZnO-MOFs:

[0041] Preparation of ZnO-MOFs: take 15g of zinc nitrate hexahydrate and 1000ml of deionized water, stir evenly to obtain a solution of zinc nitrate hexahydrate; take 8.2g of ...

Embodiment 3

[0050] Step 1: Preparation of boron nitride grafted with Schiff base:

[0051] Preparation of Schiff base: take 12mmol of 2-hydroxyacetophenone, add dropwise 35ml of anhydrous methanol, 12mmol of 2-hydroxypropylamine, react at 80°C for 6.5h, cool for crystallization, filter, add 10ml of dimethylformamide, 10ml of Water methanol, cooling and crystallization, filtration and drying to obtain Schiff base.

[0052] 10g of boron nitride was heated at 1020℃ for 3h, cooled to 27℃, washed with deionized water, filtered and dried to obtain hydroxylated nano-boron nitride; 1g of Schiff base was added, 20ml of deionized water was added, and the temperature was 50℃. The reaction was continued for 2 h to obtain boron nitride grafted with Schiff base.

[0053] Step 2: Preparation of L-arginine-grafted ZnO-MOFs:

[0054] Preparation of ZnO-MOFs: take 15g of zinc nitrate hexahydrate and 1000ml of deionized water, stir evenly to obtain a solution of zinc nitrate hexahydrate; take 8.2g of 2-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com