Metal porous body and making method thereof, current collector for cell having same

A metal porous body, porous body technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of window size reduction, easy window blockage, cracks, etc., to achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

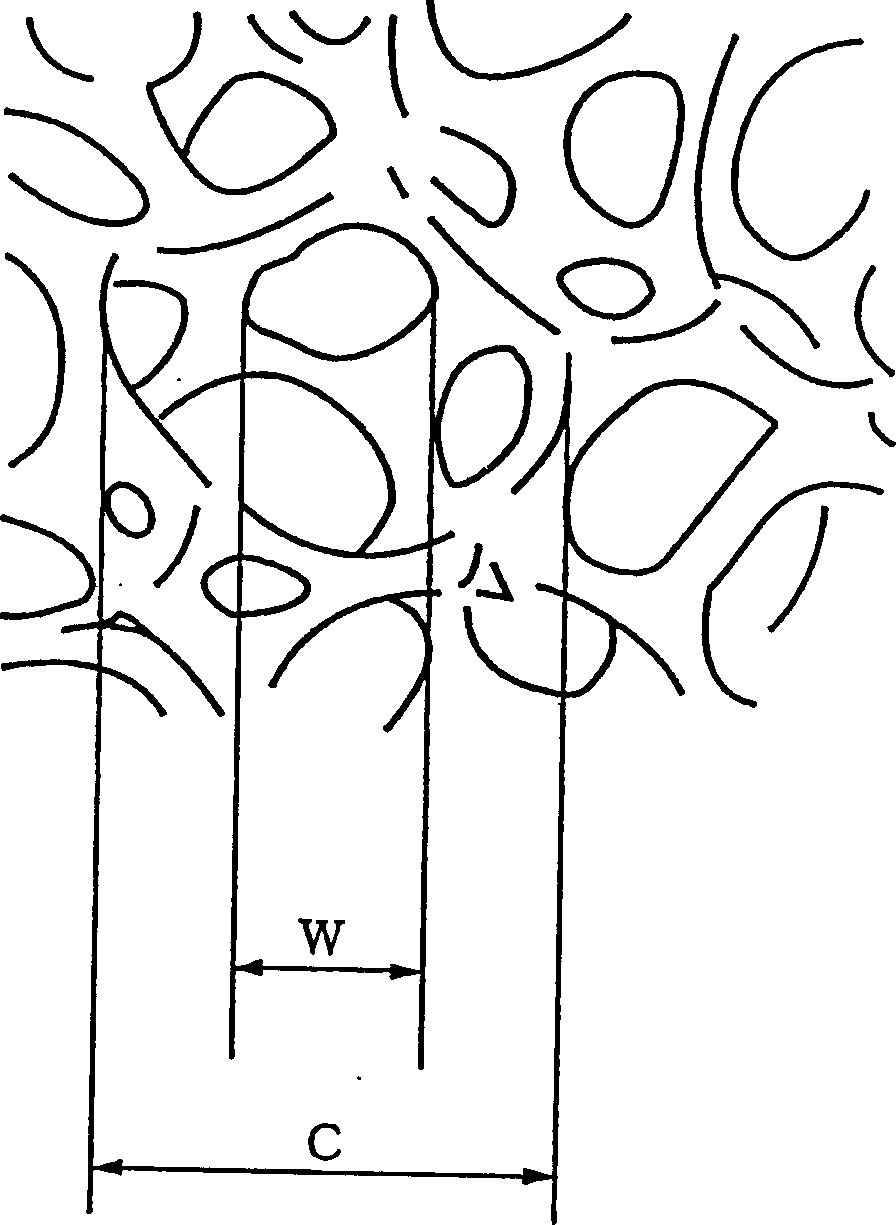

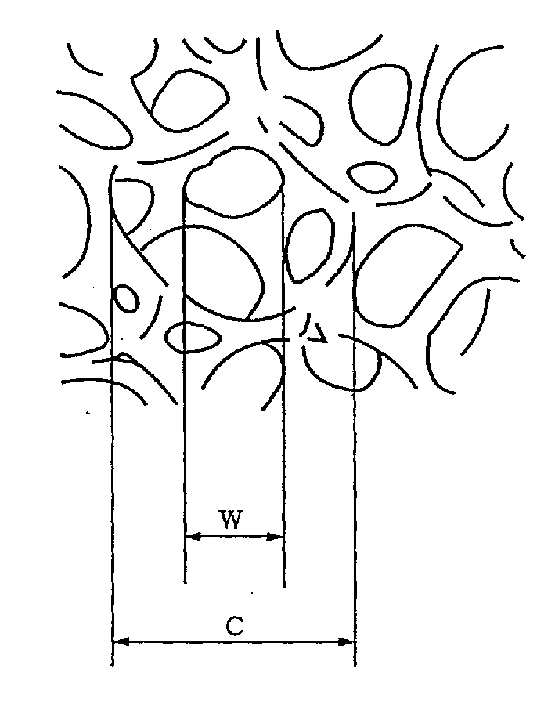

[0083] A polyurethane foam material with a thickness of 1.0 mm was used as the core. The foam has a continuous microcellular structure with cells with an average diameter of 260 microns and windows with an average diameter of 110 microns.

[0084] The core is processed through the following process to obtain a nickel coating amount of 10g / m 2 conductive porous body.

[0085] (1) degreasing treatment;

[0086] (2) washing treatment;

[0087] (3) Sensitization treatment;

[0088] (4) activation treatment;

[0089] (5) washing treatment;

[0090] (6) Electroless nickel plating treatment.

[0091] Table 1 shows the chemicals and treatment conditions used in the above (1)-(6) treatments.

[0092] serial number

deal with

chemicals

Processing temperature (℃)

Processing time (minutes)

chemicals

concentration

1

skim

Alkaline Degreaser*

100g / l.

50

10

2

washed

-

-

...

example 2

[0096]The coating liquid was prepared by the method described below. First, polyvinyl alcohol and phenolic resin were dissolved in ethanol at a weight ratio of 7:3. Then, the graphite powder with an average particle size of 0.8 μm was dispersed in the ethanol solution to make the solution concentration reach 100 g / liter. The prepared coating liquid was applied to the frame surface of the same polyurethane foam core as that used in Example 1 by the dip coating method. The coated cores were dried at 100°C. In this way, it is obtained that the coating amount is 50g. / m 2 The conductive porous body of the conductive layer.

[0097] This conductive porous body, in Watts plating tank, with this conductive porous body as cathode, at 10A / dm 2 Electroplating for 20 minutes under the current density (nickel plating). The plated porous body was heat-treated in a hydrogen atmosphere at 1000° C. for 30 minutes to remove the polyurethane foam core. Thus, a metal porous body was obtaine...

example 3

[0099] A polyurethane foam with a thickness of 1.0 mm was used as the core. The foam has a continuous microcellular structure with cells with an average diameter of 310 microns and windows with an average diameter of 122 microns. By the same treatment as in Example 1, a metal porous body was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com