Zeolite-bio combined adsorption regenerative sewage treating process

A sewage treatment method and sewage treatment technology, applied in the direction of adsorption water/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problem that the sedimentation performance is not well utilized, the hydraulic retention time is too long, and the sludge Solve problems such as high organic volatile content, achieve good sedimentation performance, good effluent quality, and low sludge yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

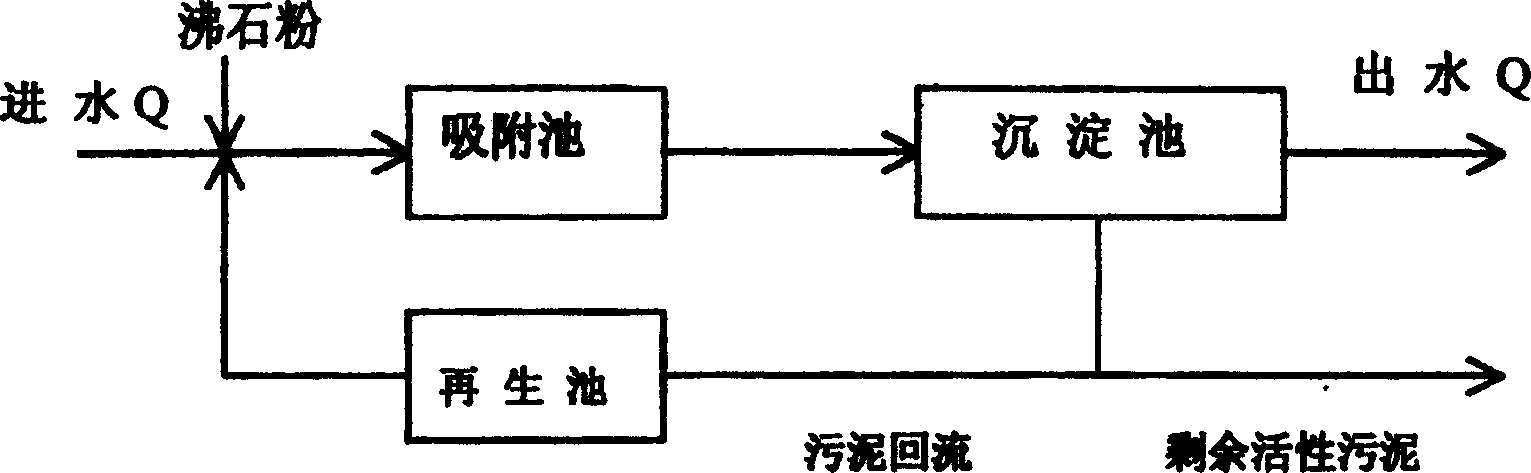

Image

Examples

Embodiment Construction

[0014] Following is the explanation that adopts the inventive method to carry out sewage treatment:

[0015] Inlet water: Q 0 =1m 3 / h, COD=150mg / L, NH 4 + -N=30mg / L, SRT=30d

[0016] Adsorption pool: add zeolite or zeolite powder to the influent,

[0017] HRT=1h, SS=10000mg / L, wherein the concentration of zeolite is 5000mg / L

[0018] N V = 1.5kgBOD 5 / m 3 .d, N S =0.2kgBOD 5 / kgMLSS.d,

[0019] It is fully stirred and mixed with the sewage by the agitator, and the air-water ratio is 15:1.

[0020] Sedimentation tank: Sedimentation time HRT = 1.5h

[0021] Regeneration tank: The sludge separated from the sedimentation tank enters the regeneration tank for biological regeneration

[0022] V=1m 3 , reflux ratio R=0.1, HRT=10h,

[0023] SS=110000mg / L, wherein the zeolite concentration is 55000mg / L,

[0024] N V =1.2kgBOD 5 / m 3 .d

[0025] Air-to-water ratio = 40:1.

[0026] Effluent: COD≤30-40mg / L, NH 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com