Poor residual hydroconversion method

A technology for residual oil and oil and gas, which is applied in the field of hydrocracking of heavy and residual oil. It can solve the problems of increasing the amount of coking in the reactor, reducing the value of distillate oil, and high condensation reaction speed, so as to improve the conversion rate of residual oil and reduce dryness. Gas yield, reduce the effect of coking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

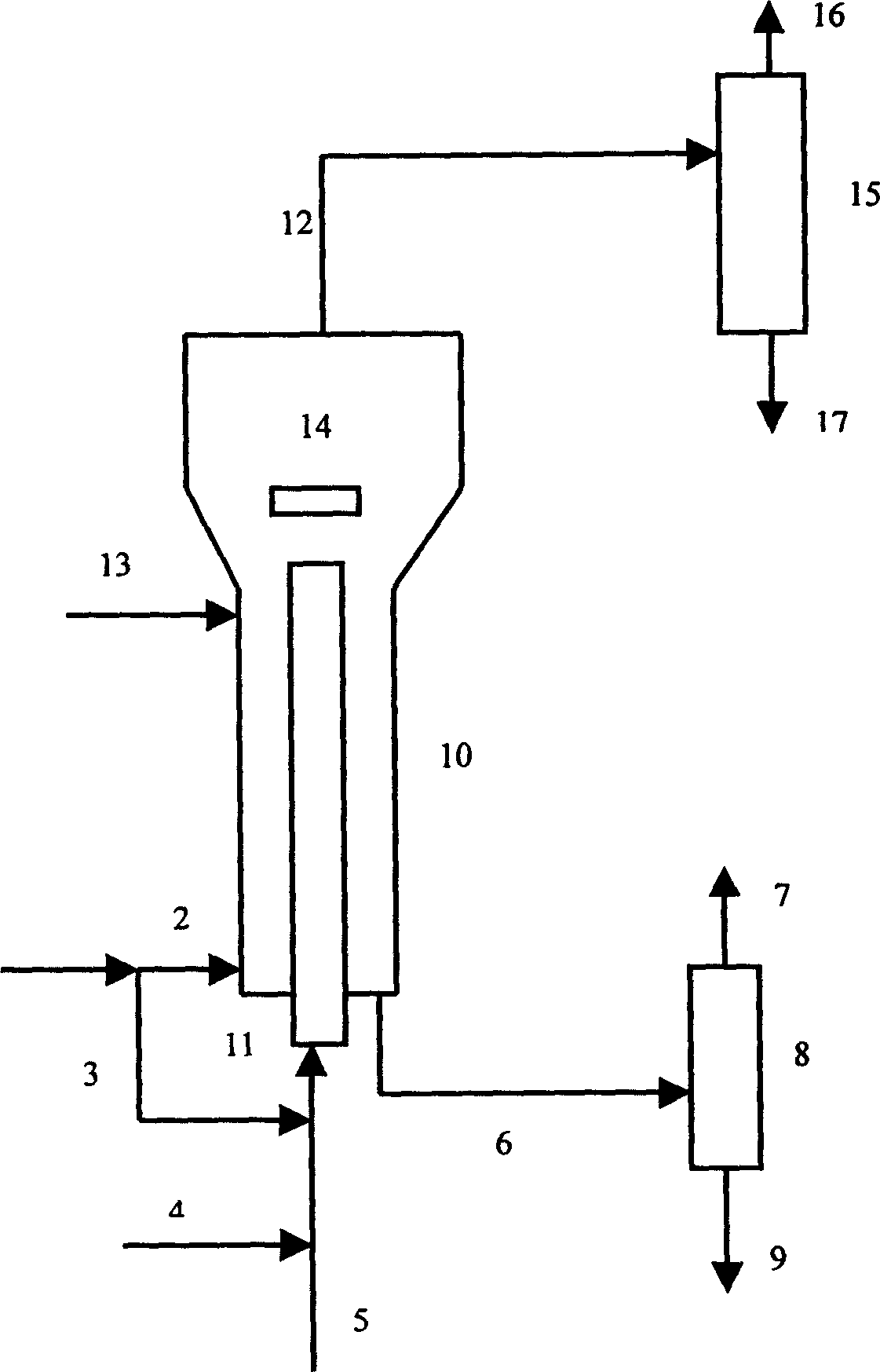

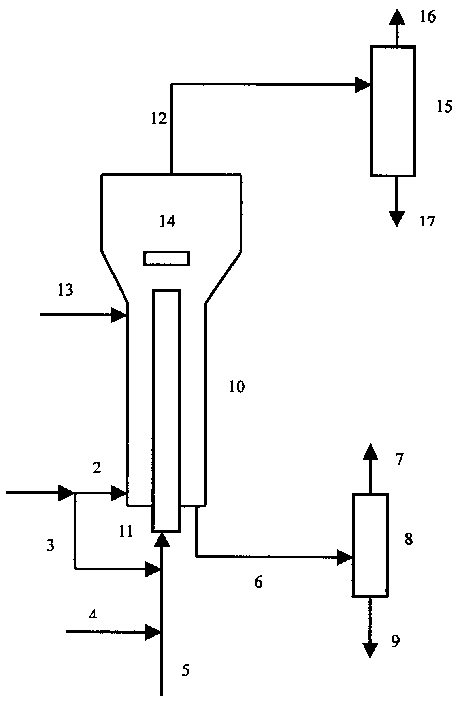

[0021] This test mainly investigates the coking performance of the tube-in-tube separation slurry bed hydrogenation process and the existing slurry bed process. The catalyst prepared in Example 9 of the published patent CN1045307C was used as the catalyst in this test. The catalyst was a water-soluble catalyst with a Mo content of 5.6w%, Ni of 0.7w%, and a p / Mo atomic ratio of 0.087. In this experiment, the residual oil slurry bed hydrogenation reaction was carried out on a continuous test device. Based on the total weight of the feed oil and the catalyst entering the reactor, the content of the catalyst in the reactor is 300 ppm. The properties of raw materials and aromatic feed are shown in Table-1, and the operating conditions and reaction results are shown in Table-2. Table-2 shows that the coking performance of the tube-in-tube separation slurry bed hydrogenation process is much lower than the existing slurry bed process, and the tendency of excessive cracking is also lower t...

Embodiment 7~10

[0027] This test mainly investigates the coke deposition of the slurry bed process of the present invention and the existing slurry bed process. The catalyst was the same as in Examples 1 to 6, and the device operated for 360 hours. The test results are shown in Table-3, and it can be seen from Table-3 that the amount of coke deposition in the slurry bed process of the present invention is much smaller than that of the existing slurry bed process.

[0028] Example

[0029] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com