Bactericidal chitosan and its preparation and method for making cellulose solvent weaving liquid

The technology of chitosan and antibacterial agent is applied in the field of antibacterial agent chitosan and its preparation and preparation of cellulose solvent spinning solution, and achieves the effects of good moisture retention, obvious antibacterial effect and lasting antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

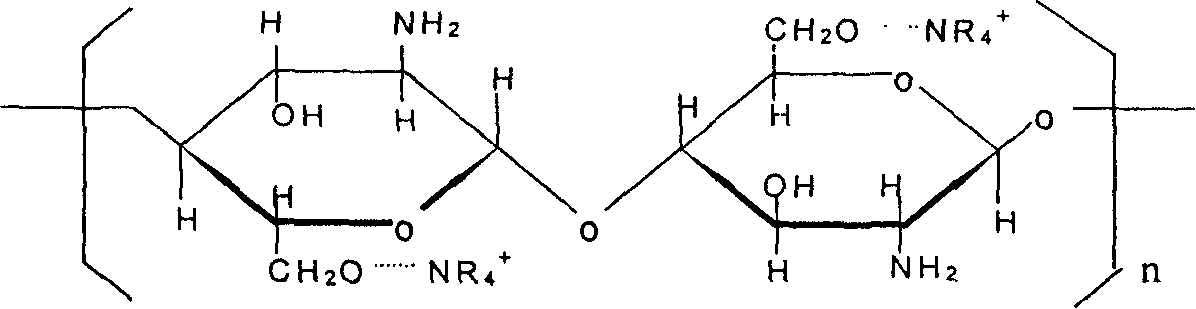

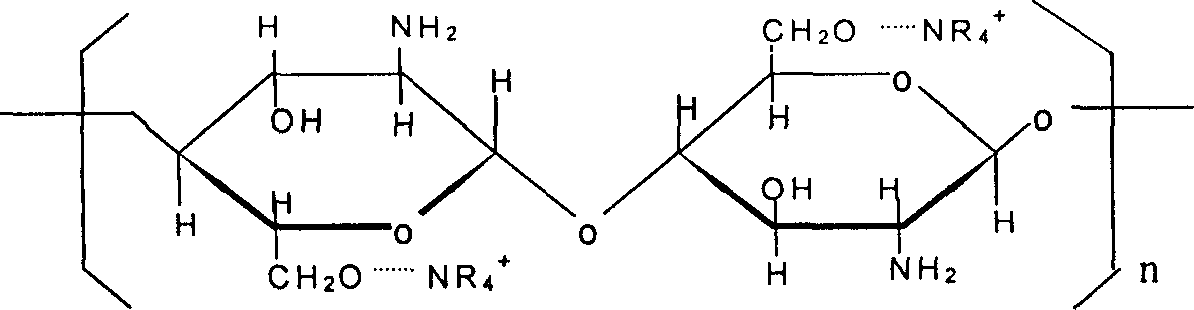

Image

Examples

Embodiment 1

[0015] Embodiment one, O-2'-hydroxypropyltrimethylammonium chloride chitosan and cellulose composite antibacterial fiber

[0016] 1. Radiation degradation of chitosan: Chitosan with a molecular weight of 1.08 million and a degree of deacetylation of 85% is produced by Co 60 The radiation source is irradiated with a radiation dose of 60 kGy to obtain chitosan oligomer A with a molecular weight of 100,000 to 200,000 and a deacetylation degree of 86%.

[0017] 2. Preparation of O-2'-hydroxypropyltrimethylammonium chloride chitosan:

[0018] ① Synthesis of N-benzylidene chitosan: Weigh 300 grams of A, dissolve in 12 liters of 10%wt acetic acid solution, add 1580 grams of benzaldehyde dropwise, and react at 50°C for 20 hours. Adjust the pH to neutral with lye and filter. The filter cake was washed 2 to 3 times with methanol, and dried at 60°C to obtain light yellow solid B.

[0019] ②Preparation of O-quaternary ammonium salt-N-benzylidene chitosan: 280 grams of B, reacted with 5...

Embodiment 2

[0025] Embodiment two, O-methacryloyloxytrimethylammonium chloride chitosan and cellulose composite antibacterial fiber

[0026] 1. The radiation degradation of chitosan: do by embodiment one, 1

[0027] 2. Preparation of O-methacryloxytrimethylammonium chloride chitosan:

[0028] 1. the synthesis of N-benzylidene chitosan: according to embodiment one, 2.1. do

[0029] ② Preparation of O-quaternary ammonium salt-N-benzylidene chitosan: B280g, react with 5 liters of isopropanol and 1300g of methacryloxytrimethylammonium chloride at 60°C for 10 hours . After filtering, the filter cake was washed 2-3 times with methanol, and dried at 60°C to obtain white solid C.

[0030]③The preparation of O-methacryloxytrimethylammonium chloride chitosan: add 300 grams of C in 5 liters of 2.5mol / liter hydrochloric acid-ethanol solution, after fully stirring, remove ethanol, add 2.5 liters of water again, fully Dissolve, and finally precipitate the product with acetone, wash the precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com