Modified collagen fiber and its preparing process

A technology for skin collagen and fiber, applied in the field of modified skin collagen fiber and its preparation, can solve the problem of inability to undergo chemical reaction, and achieve the effects of reducing chromium pollution, less chromium dosage, and clear water bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

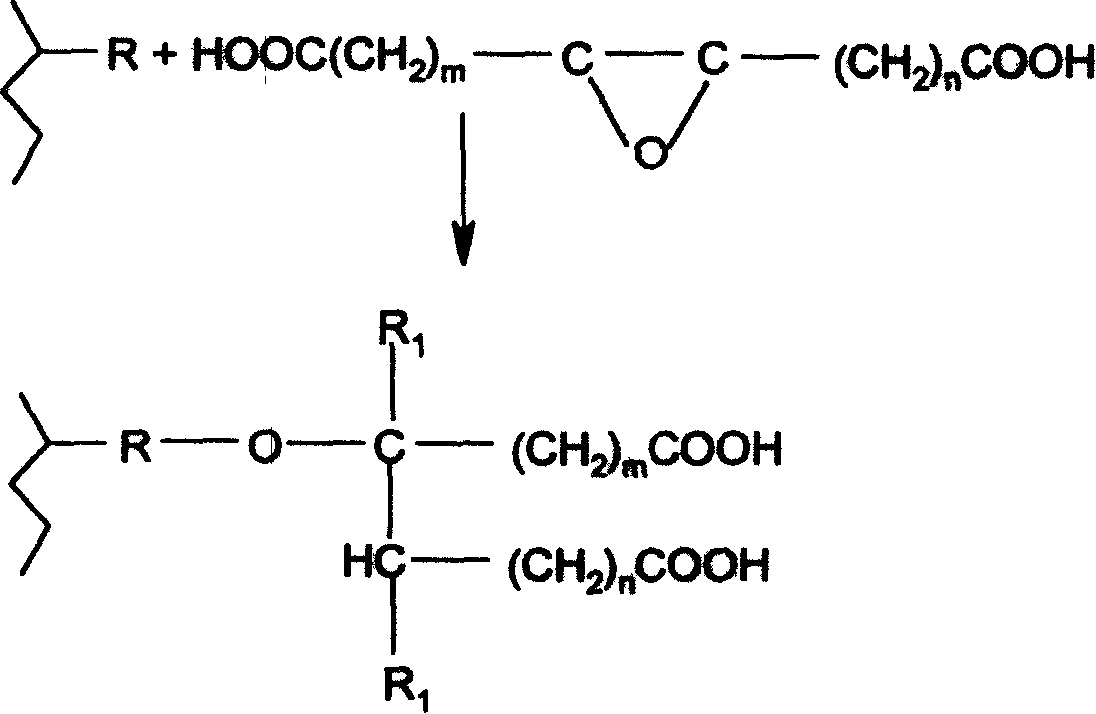

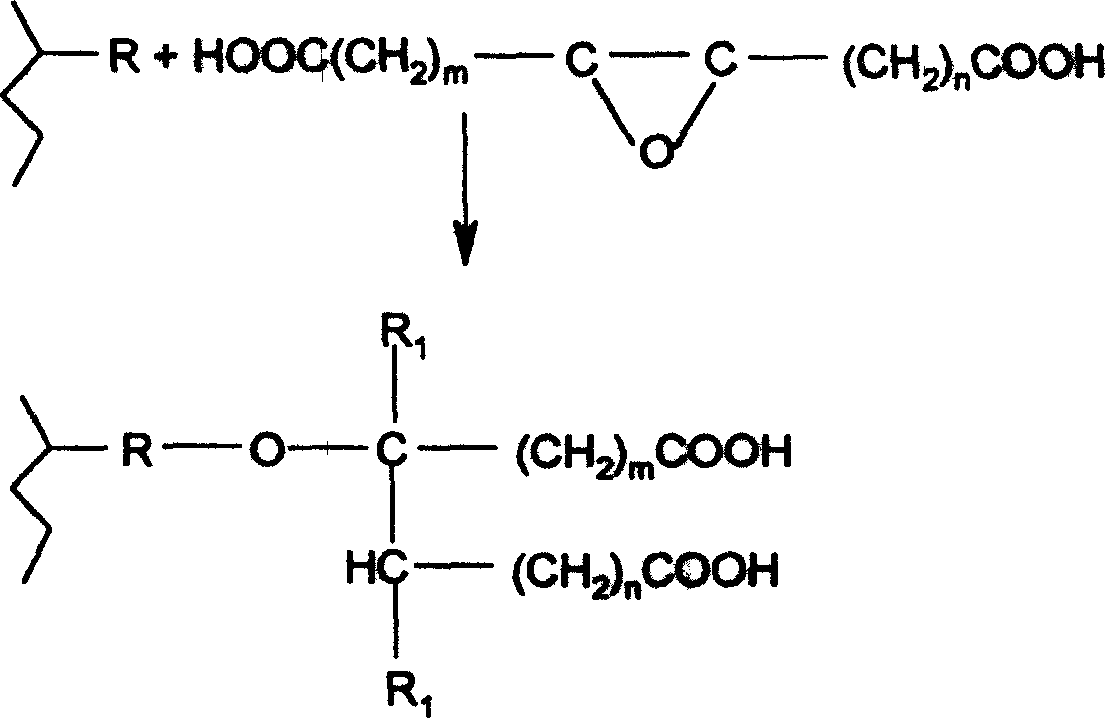

[0029] 1.1 Add 100 kg of pickled natural pigskin collagen fibers, 1 kg of epoxy succinic acid, 0.1 kg of salicylic acid, and 0.2 kg of tetramethylammonium chloride into the drum, and adjust the pH to 2.8 to 3.2 with acid and alkali , reacted at a temperature of 25°C for 1 hour to obtain epoxysuccinic acid modified pigskin collagen fibers, the reaction formula is as follows:

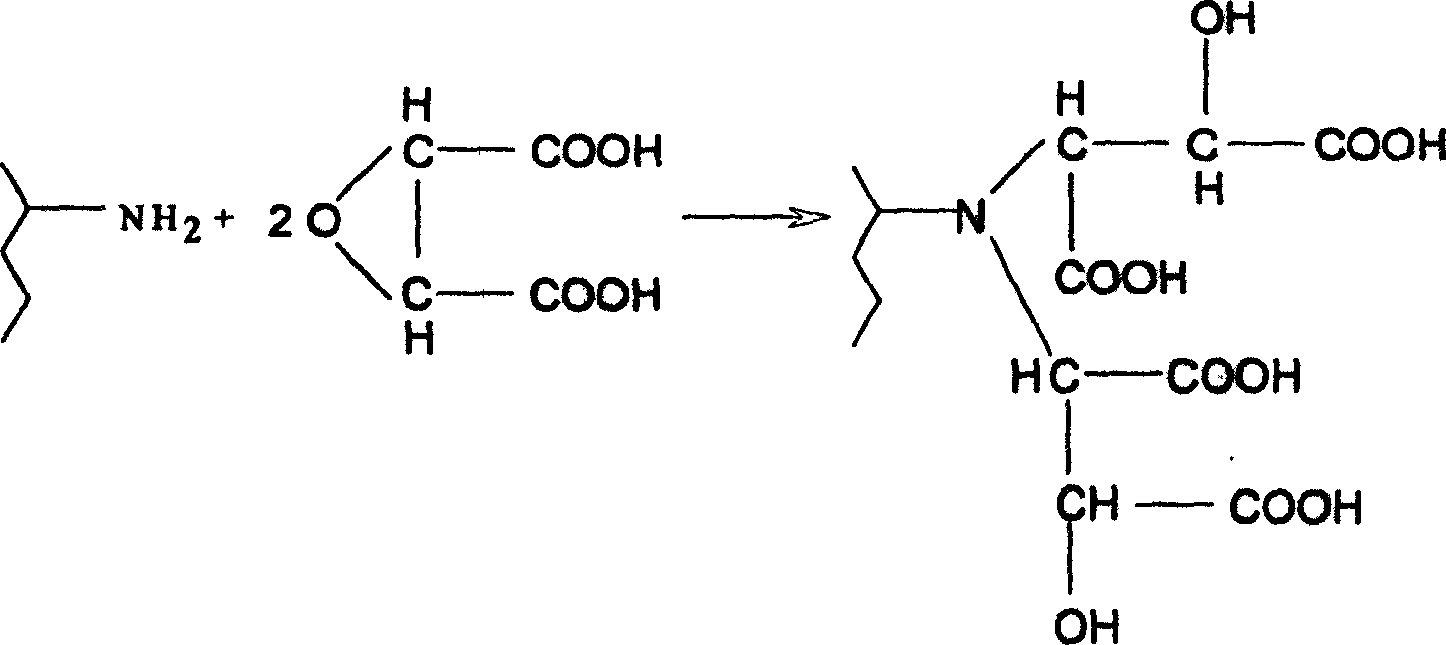

[0030] 1) Reaction of succinic acid with amino groups on collagen fibers

[0031]

[0032] 2) Reaction of succinic acid with phenolic hydroxyl groups on collagen fibers

[0033]

[0034] 3) Reaction of succinic acid with hydroxyl groups on collagen fibers

[0035]

[0036] 4) Reaction of succinic acid with mercapto groups on collagen fibers

[0037]

[0038] 5) Reaction of succinic acid with guanidine groups on collagen fibers

[0039]

[0040] 1.2 Tanning

[0041] Add 4.5 kg of chromium powder in the drum, and continue to rotate for 2 hours. If the wet blue skin cutting process is adop...

Embodiment 2

[0043] 2.1 Add 100 kg of natural cowhide collagen fiber after pickling, 1.2 kg of epoxy glutaric acid, 0.1 kg of salicylic acid, and 0.2 kg of tetramethylammonium chloride into the drum, adjust the pH to 3.0 with acid and alkali, and The reaction was carried out at 25°C for 2 hours to obtain epoxyglutaric acid-modified bovine collagen fibers, and the reaction principle was the same as in Example 1.

[0044] 2.2 Tanning

[0045] Add 4.5 kg of chromium powder into the above-mentioned drum, continue to rotate for 1.5 hours, add baking soda to extract alkali, and slowly raise the pH value to about 4.0, add 60-70°C hot water to 200% liquid ratio after half an hour, and turn Stop the drum for 6 hours overnight, and turn it on for 0.5 hours in the next morning to exit the drum. The temperature of the drum exit is ≥ 42 ° C, and the measured shrinkage temperature is > 110 ° C. The subsequent processes such as neutralization, dyeing and fatliquoring are operated according to conventiona...

Embodiment 3

[0047] 3.1 Add 100 kg of pickled natural sheepskin collagen fibers, 1.5 kg of epoxy sebacic acid, 0.1 kg of salicylic acid, and 0.3 kg of tetramethylammonium chloride into the drum, adjust the pH to 2.8 with acid and alkali, and Rotating reaction at 25°C for 1.5 hours to obtain epoxy sebacic acid modified sheepskin collagen fibers, the reaction principle is the same as in Example 1.

[0048] 3.2 Tanning

[0049] Add 4.5 kg of chromium powder into the above drum, continue to rotate for 1.5 hours, add sodium bicarbonate to extract alkali, and slowly raise the pH value to about 3.9, add 60-70°C hot water to 200% liquid ratio after half an hour, and rotate Stop the drum for 3 hours overnight, turn the drum for 0.5 hours in the next morning, and leave the drum at a temperature ≥ 42°C. After standing for 24 hours, the measured shrinkage temperature is > 110°C. The subsequent processes such as neutralization, dyeing and fatliquoring follow the conventional method operate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com