Microgravity infiltrating irrigation tube, its preparation process and application in greenhouse

A technology for greenhouses and infiltration irrigation pipes is applied in the fields of application, botanical equipment and methods, horticulture, etc., and can solve the problems of restricting the development of crop roots, inconvenient field operations of equipment, and easy clogging of irrigation equipment. The effect of low production cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw material components and weight percentages of microgravity irrigation pipe: recycled rubber powder (particle size ≤0.25mm) 65% (w / w), high-pressure polyethylene 23% (w / w), low-pressure polyethylene 5 % (w / w), polyester 3.5% (w / w), blowing agent 0.7% (w / w), polyethylene wax 0.3% (w / w), barium stearate 0.3% (w / w) , carbon black 0.2% (w / w), calcium carbide 2%;

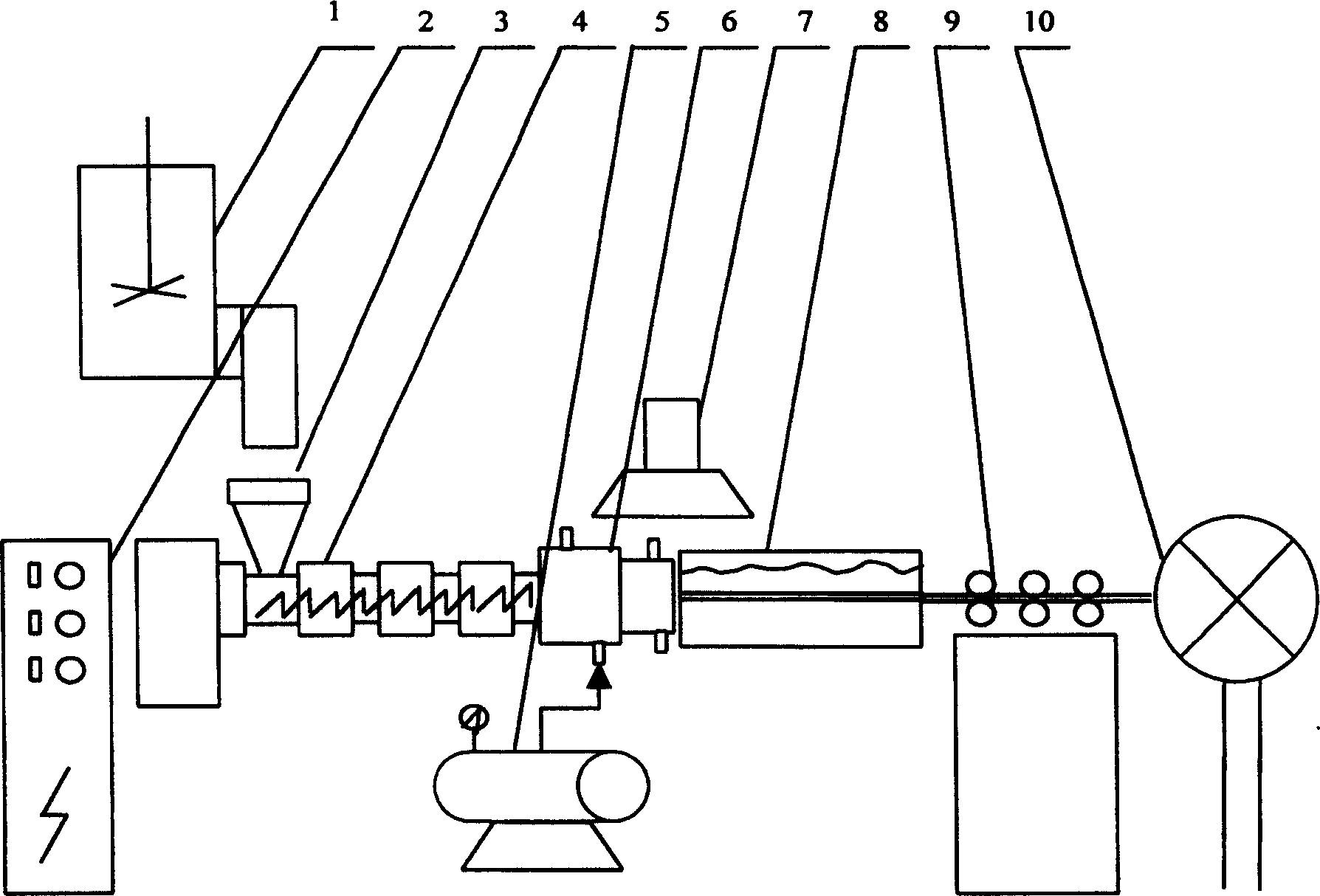

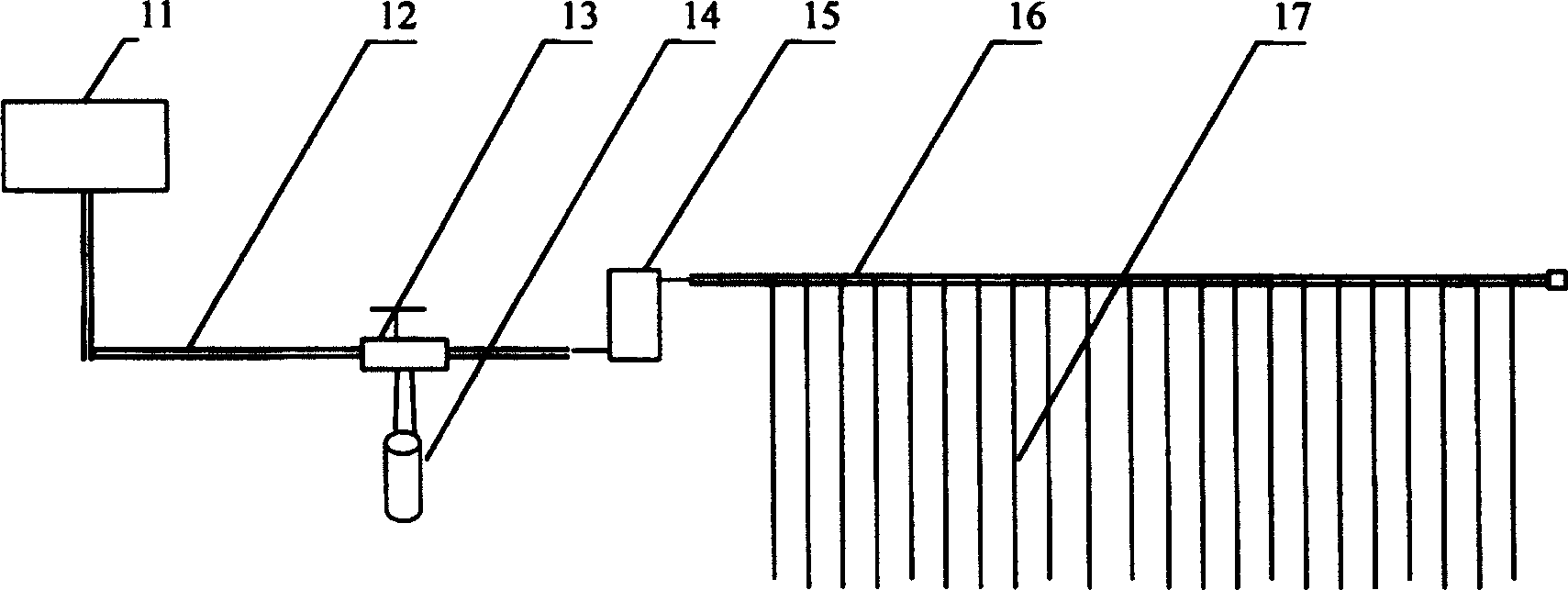

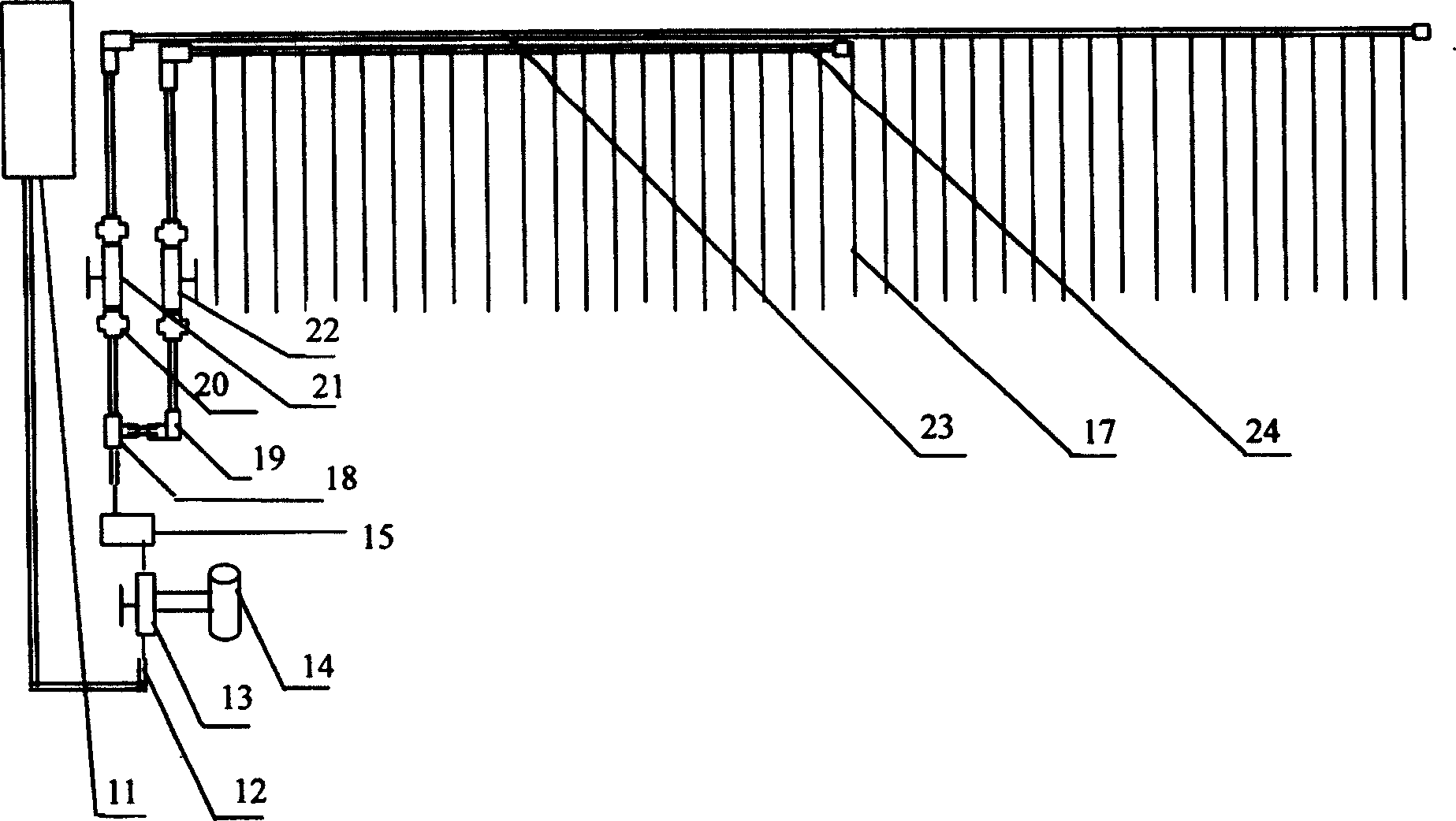

[0039] Such as figure 1 The schematic diagram of the microgravity permeation irrigation pipe production equipment shown in the figure, the above ingredients are put into the mixing tank 1 of the mixer according to the proportion and stirred evenly, the temperature is raised to 90°C, preheated and plasticized, continuously stirred for 30 minutes, and the temperature is lowered to 80°C The following materials are fed into the extruder 4 from the hopper 3, controlled by the power box 2, and melted and plasticized at 210°C, extruded through the mold 6, inflated by the air pump 5, exhausted by the air pump 7, and c...

Embodiment 2

[0041] The difference from Example 1 is:

[0042] Take 70% (w / w) of regenerated rubber powder (particle size is about ≤0.25mm), 20% (w / w) of high-pressure polyethylene, 4% (w / w) of low-pressure polyethylene, 2.5% (w / w) of polyester w), AC foaming agent 1% (w / w), paraffin wax 0.2% (w / w), stearic acid 0.1% (w / w), carbon black 0.2% (w / w), manganese oxide 0.5% ( w / w), calcium carbide 1.5%; put the above ingredients into a mixer in proportion, stir and heat up to 100°C, preheat and plasticize, continue stirring for 20 minutes, stir and cool down to below 80°C, discharge, and melt at 200°C After plasticizing, it is extruded through the mold, cooled, pulled, and rolled to form a product. The outer diameter of the infiltration irrigation pipe is 20mm, the wall thickness of the pipe is 3.0mm, the distribution range of the micropores in the pipe wall is 0.1-0.3mm, and the water permeability 40-50L / h·m.

Embodiment 3

[0044] The difference from Example 1 is:

[0045] Take regenerated rubber powder (particle size is ≤0.177mm) 60% (w / w), high pressure polyethylene 27% (w / w), low pressure polyethylene 7% (w / w), blowing agent 0.7% (w / w), paraffin 0.3% (w / w), manganese oxide 0.2% (w / w), barium stearate 0.3% (w / w), carbon black 0.2% (w / w), magnesium hydroxide 0.3% ( w / w), calcium carbide 4%; put the above ingredients into the mixer in proportion, stir and heat up to 95°C, preheat and plasticize, continue stirring for 15 minutes, stir and cool down to below 80°C, discharge, and melt at 190°C After plasticizing, it is extruded through the mold, cooled, pulled, and rolled to form a product. The outer diameter of the infiltration irrigation pipe is 10mm, the wall thickness of the pipe is 2.0mm, and the distribution range of micropores in the pipe wall is 0.02-0.1mm. 10-30L / h·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com