Method for detecting organic molecule in solution by nano material catalytic light emitting and detector

A nano-material and luminescence detection technology, which is applied in the field of nano-material catalytic luminescence detection of organic molecules in solution, to achieve the effects of easy operation, good repeatability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

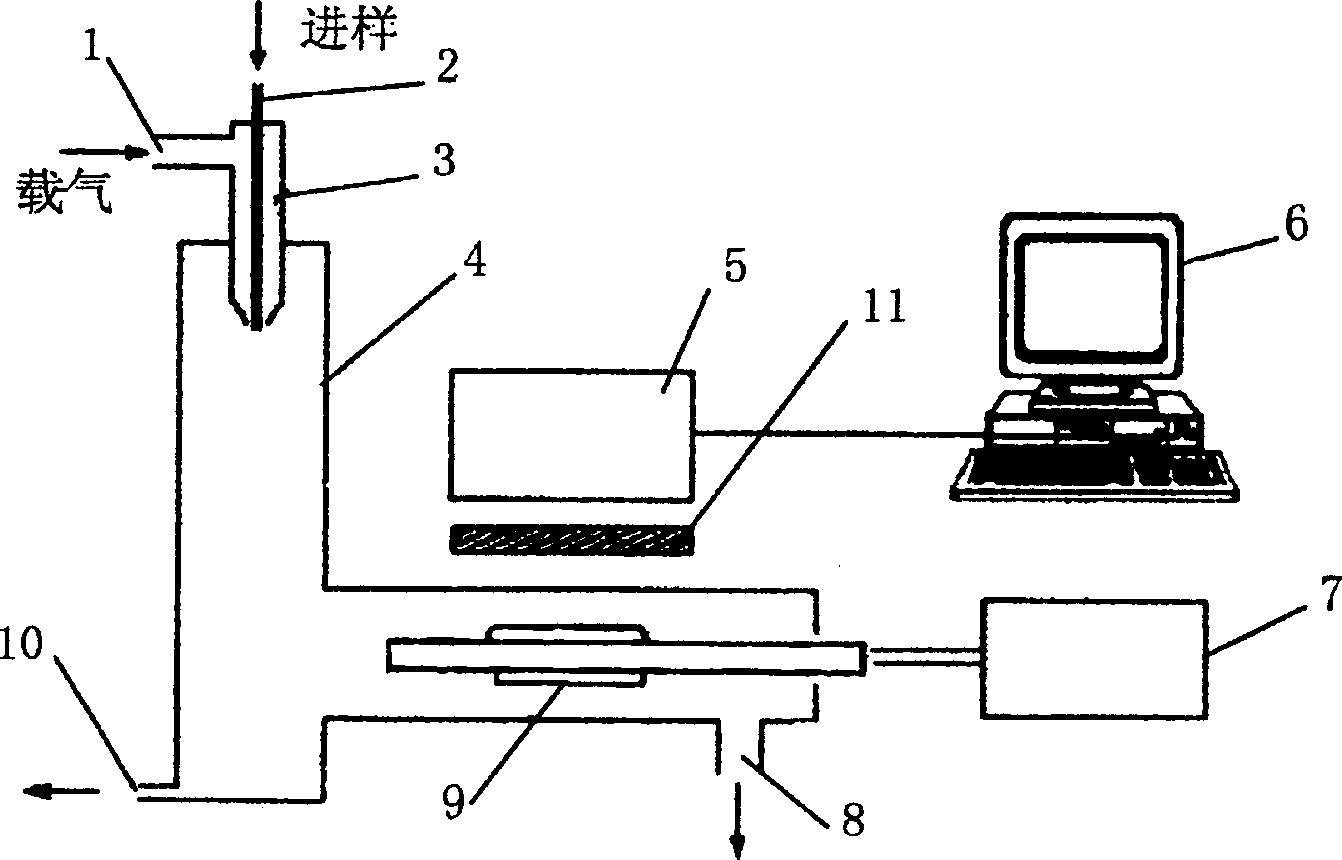

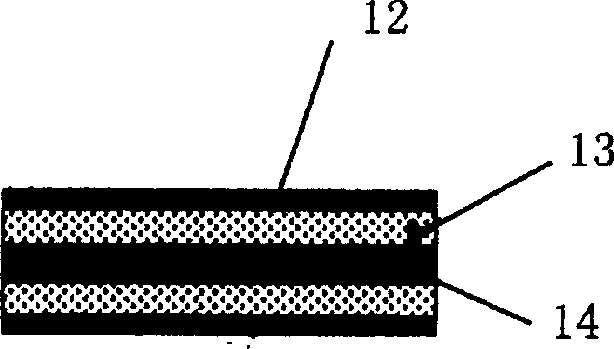

Method used

Image

Examples

Embodiment 1

[0010] Embodiment one: the nanomaterial γ-Al 2 o 3 It is coated or sintered on the surface of the ceramic heater in the form of powder or film, and the temperature is raised to 500°C and kept for 30 minutes to eliminate the interference of adsorbate. The working temperature is 100°C, and the carrier gas is N 2 :O 2 Mixed gas (ratio in the range of 1:99-99:1), the flow rate is 10L / min, and the detection wavelength can be changed from 400-700nm. Take a quantitative sample solution, such as 50 μL of sucrose or glucose or other sugar compound aqueous solution, inject it into the detector from the injection port, the test solution is atomized and brought to the catalytic luminescent device for reaction, and the optical signal is detected by the photomultiplier tube , the computer automatically collects the signal. The optical signal changes linearly with the concentration of the solution. For example, for sucrose solution, the linear range is 10-1000μg / mL; for glucose solution,...

Embodiment 2

[0011] Embodiment two: the nanomaterial SrCO 3 It is sintered on the surface of the ceramic heater in the form of powder or film, and the temperature is raised to 500°C and kept for 30 minutes to eliminate the interference of adsorbate. The working temperature is 30°C, and the carrier gas is N 2 :O 2 Mixed gas (ratio in the range of 1:99-99:1), the flow rate is 0.5L / min, and the detection wavelength can be changed from 400-700nm. Take a quantitative solution, such as 50 μL of ethanol and other alcohol compound solutions, inject it into the detector through the injection port, the test solution is atomized and brought to the catalytic luminescent reaction device for reaction, the optical signal is detected by the photomultiplier tube, and the computer The signal is collected automatically, and the optical signal changes linearly with the concentration of the solution. For example, for ethanol solution, the linear range is 10-1000μg / mL.

Embodiment 3

[0012] Example three: the nanomaterial γ-Al 2 o 3 It is sintered on the surface of the ceramic heater in the form of powder or film, and the temperature is raised to 500°C and kept for 30 minutes to eliminate the interference of adsorbate. The working temperature is 250°C, and the carrier gas is N 2 :O 2 Mixed gas (ratio in the range of 1:99-99:1), the flow rate is 15L / min, and the detection wavelength can be changed from 400-700nm. Take a quantitative sample solution, such as 50 μL of valine or other amino acid compound aqueous solution, inject it into the detector from the injection port, the test solution is atomized and brought to the catalytic luminescent device for reaction, and the optical signal is detected by the photomultiplier tube , the computer automatically collects the signal. The optical signal changes linearly with the concentration of the solution, such as for valine solution, the linear range is 20-1000μg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com