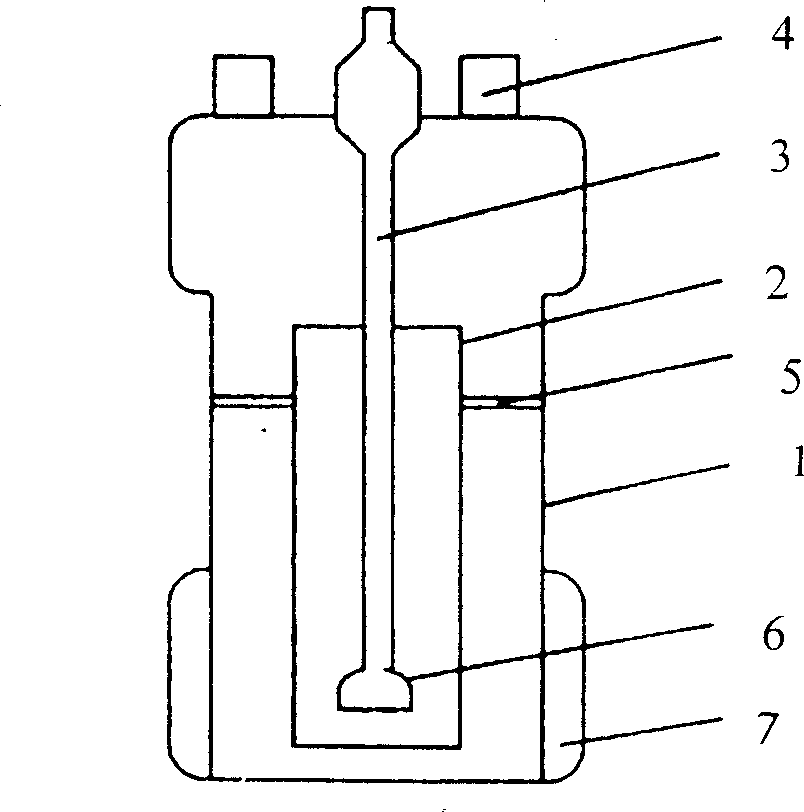

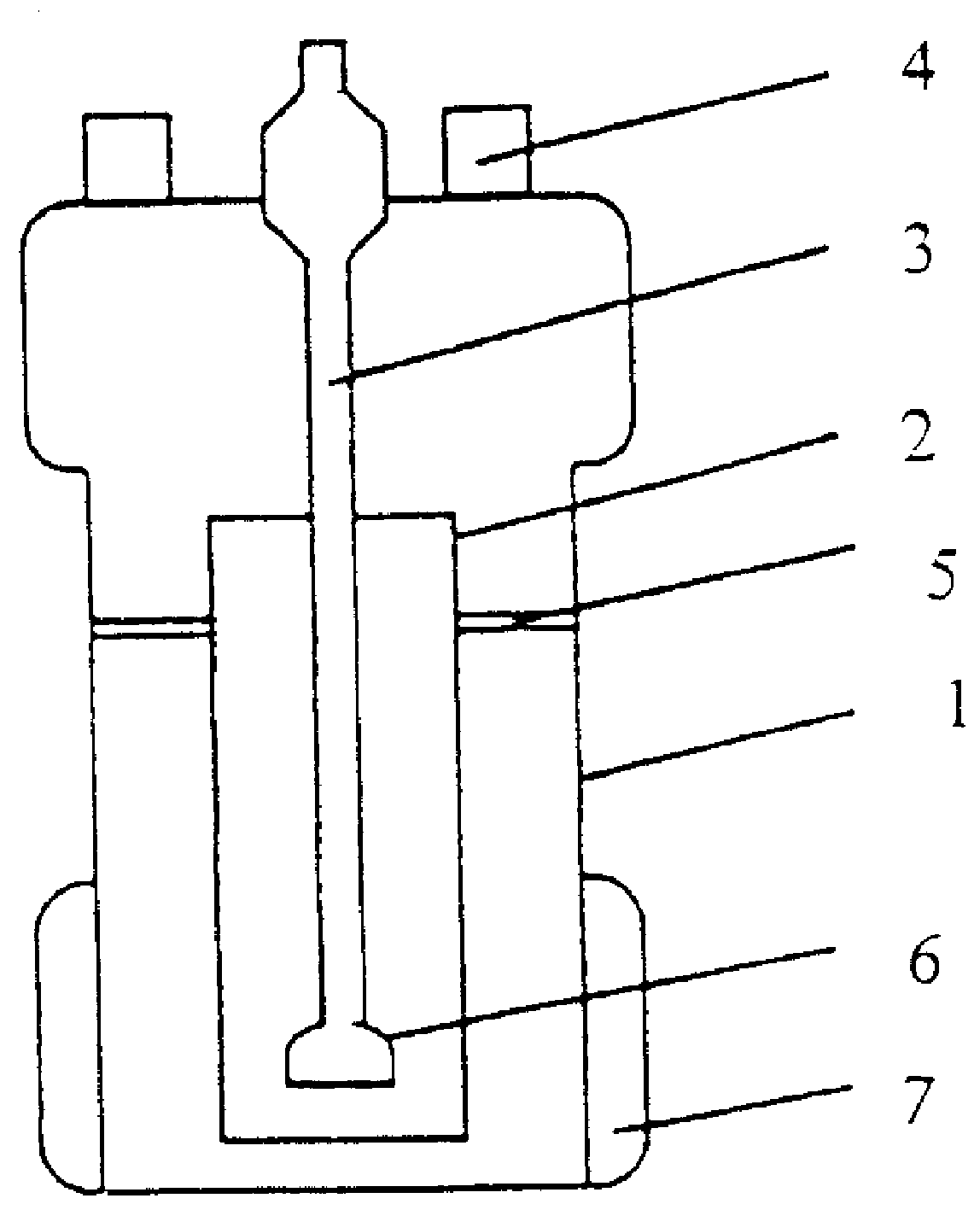

Integral pneumatic lifting photobiological reactor and use thereof

A photobioreactor and airlift technology, applied in the field of closed photobioreactors, can solve the problems of inconvenient laboratory use, inconvenient processing and manufacturing, and long time-consuming use, etc., to achieve shortened cultivation cycle, stable operation, mixed full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The tank body 1 has a diameter of 182 mm, the riser 2 has a diameter of 131 mm, and the effective volume of the entire reactor is 2.5 liters. The gas distributor 6 is a glass sand sintered perforated plate with a diameter of 30 mm and a pore diameter of 80 μ. The whole reactor is made of hard borosilicate glass. Four to eight 20W energy-saving fluorescent lamps are evenly distributed around the tank to provide light. The single-celled marine cyanobacterium Synechococcus.sp.PCC.7002 is cultivated in the reactor, and Medium A is used as the medium, and 1% CO is introduced from the air pipe 3 2 Air carbon dioxide mixed gas, the gas volume is 400ml / min, and the inoculation density is 0.13g / L dry weight. After culturing for 5 days, the final density of algae cells reached 2.36g / L.

Embodiment 2

[0031] An airlift photobioreactor with an effective volume of 2.5 liters as in Example 1. The mixed nutrient culture of single-celled marine cyanobacteria Synechococcus.sp.PCC.7002 is carried out in this reactor. Medium A is used as the medium, 3g / L of glucose is added, and 1% CO 2 Air carbon dioxide mixed gas, the gas volume is 400ml / min, and the inoculation density is 0.13g / L dry weight. After culturing for 5 days, the final density of algae cells reached 3.6g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com