High pure attapulgite clay and preparation method

A technology of attapulgite and attapulgite, which is applied in the field of high-purity attapulgite and its preparation, can solve problems affecting the use effect and range of use, and achieve the effect of simple and easy purification process, easy-to-obtain raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1: the clay ore of gray-green natural attapulgite containing 17.2% of quartz and 83.8% of attapulgite clay, firstly crushed to 25 microns (200 mesh), was added at 40°C at 1:20, containing 1% sodium polyphosphate In the homogeneous aqueous solution, after 20 minutes of mechanical stirring and 10 minutes of ultrasonic vibration alternately for 3 times, let it stand for 30 minutes to produce obvious off-white suspension and black precipitate layering, pump out or pour out the upper suspension, and vacuum at 80 ~ 100 ° C Spray drying to obtain attapulgite clay particles with a clay content of 99.5% and a whiteness of 87 for the attapulgite.

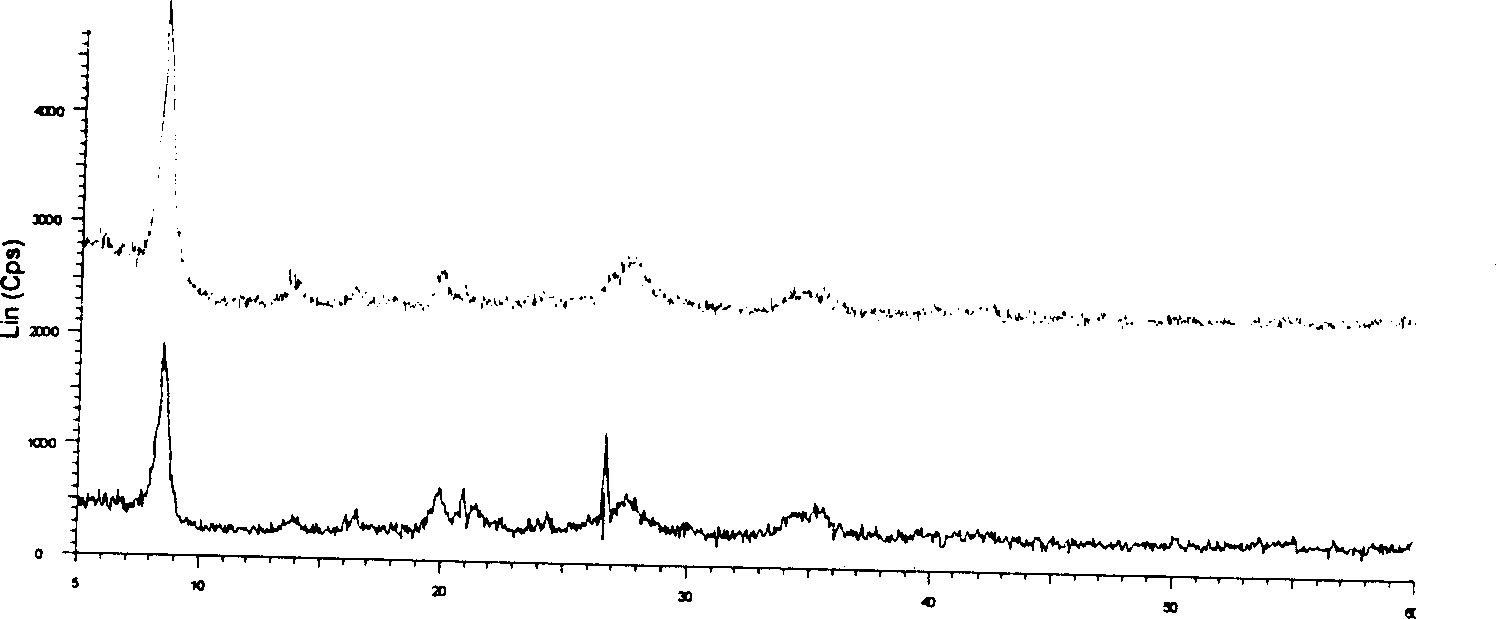

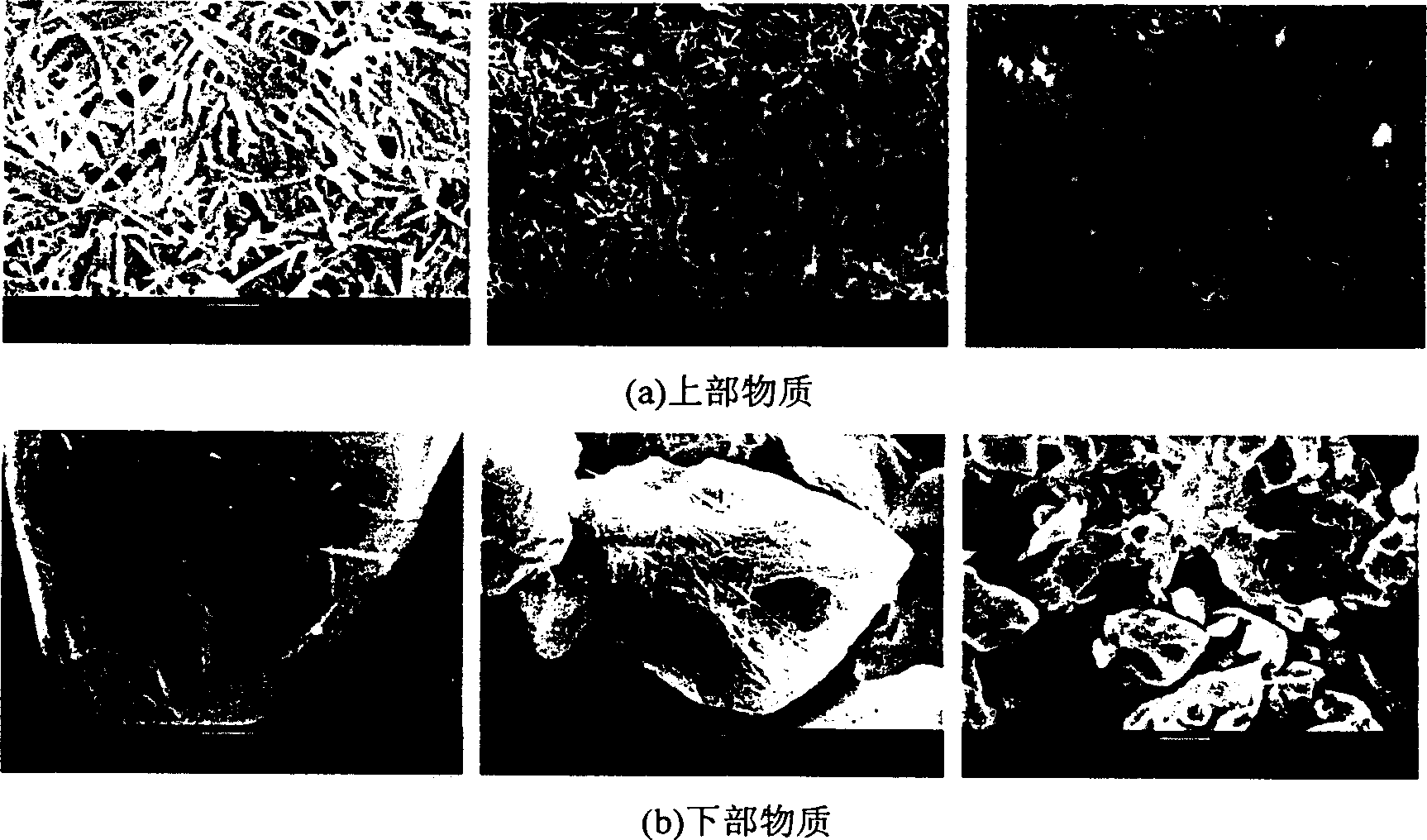

[0018] The x-diffraction and scanning electron microscope detection of the attapulgite clay before and after purification are as follows: figure 1 and Figure 2 Show.

example 2

[0019] Example 2: The clay ore of gray-white natural attapulgite containing dolomite and quartz 47.5% is first crushed to 48 microns (300 orders), and added in a homogeneous aqueous solution containing 2.5% sodium silicate at 60° C. by 1:15, mechanically for 30 minutes Stirring and 20min ultrasonic oscillation alternate twice each, then stand still for 60min, pour out the upper suspension, and carry out centrifugation to obtain the clay crystal slurry of the attapulgite, and then vacuum freeze-dry at 40°C to obtain the clay content of the attapulgite 90% attapulgite clay particles with a whiteness of 91.

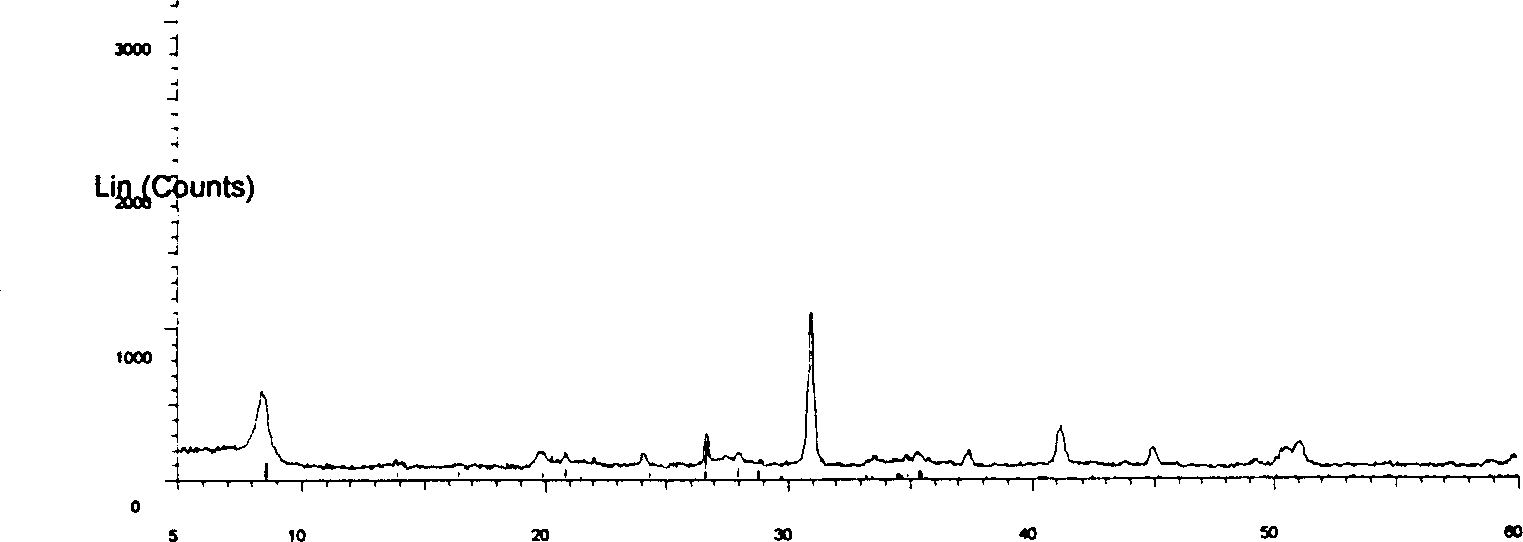

[0020] The x-diffraction and scanning electron microscope detection of the attapulgite clay before and after purification are as follows: image 3 and Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com