Synthesis of micron and nano zinc oxide fiber by alloy gas controllable evaporation method

A nanofiber and zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of complex process, difficult scale, low yield, etc., and achieve rapid production process, controllable dimension, easy large-scale continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

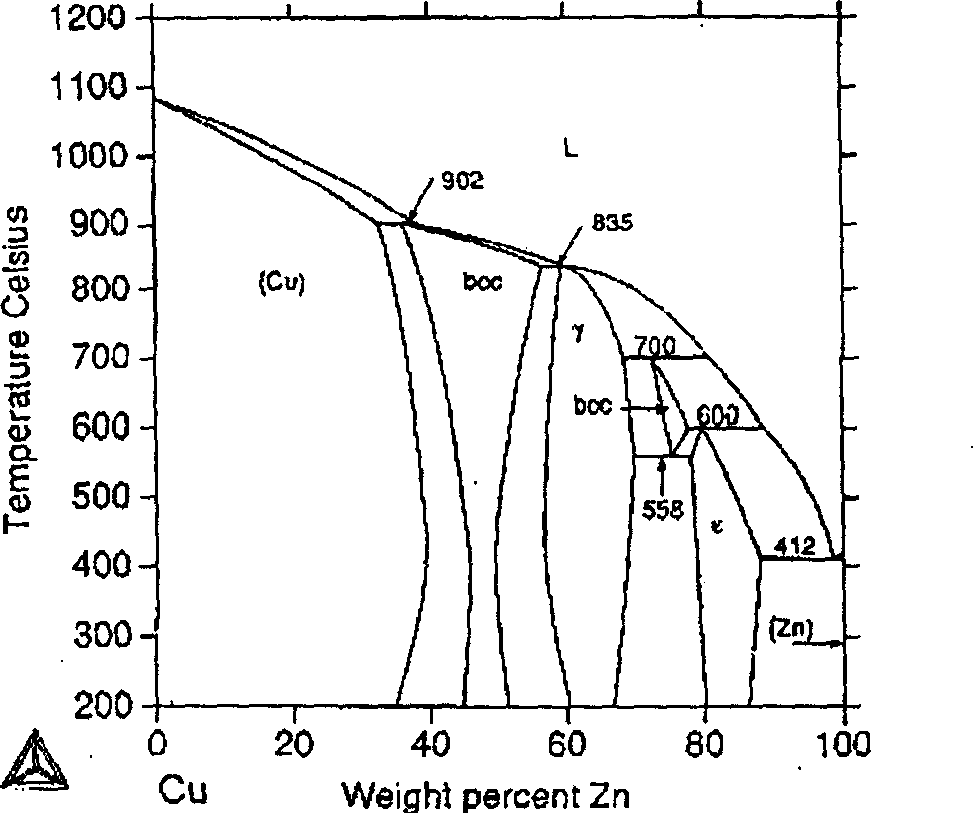

[0020] Example 1: In an open high-temperature silicon-molybdenum rod program temperature-controlled reaction furnace (GWDL-1KY, Luoyang Weida High Temperature Instrument Co., Ltd.), at 1250 ° C, copper-zinc mixed powder with a copper-zinc weight ratio of 50% was mixed in the air Put it in the reaction temperature zone, and the reaction ends in 10 minutes. A large amount of white flocculent product can be received in the downwind direction.

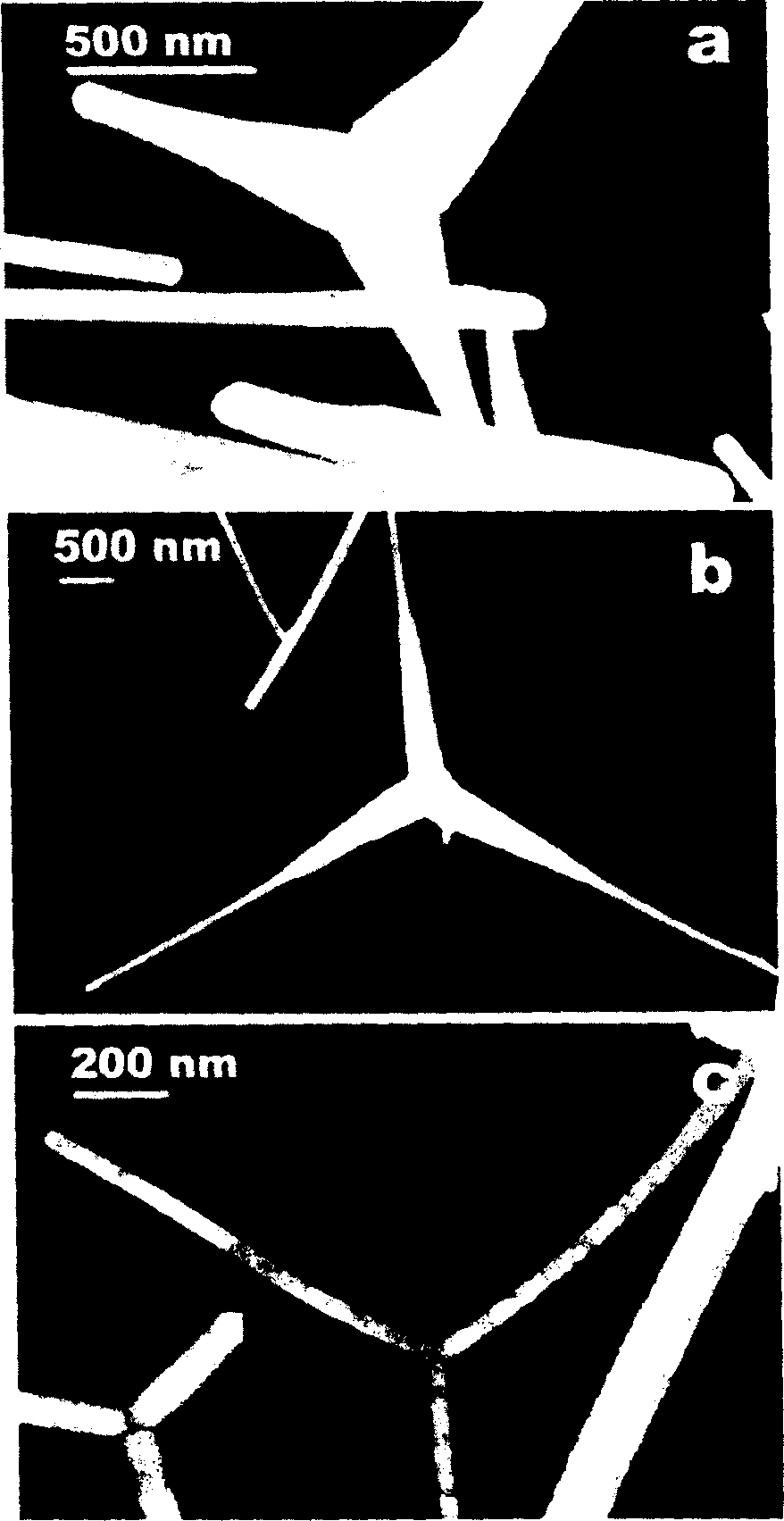

[0021] XRD diffraction analysis shows that the white floc product is zinc oxide with excellent crystallization degree, and no other phases of copper or copper oxide appear. The zinc oxide observed with a scanning electron microscope (SEM) is a uniform three-needle or four-needle fiber (see image 3 ). The dimensions of a single needle are 100nm and the length is 1.5um.

Embodiment 2

[0022] Embodiment 2: In the open high-temperature silicon-molybdenum rod programmed temperature control reaction furnace, at 1250 ° C, a commercially pure brass block (copper content 50wt%-65wt%) is placed in the reaction temperature zone in the air, and reacted for 15 minutes Finish. A large amount of white flocculent product can be received in the downwind direction.

[0023] XRD diffraction analysis shows that the white floc product is zinc oxide with excellent crystallization degree, and no other phases of copper or copper oxide appear. With a scanning electron microscope (SEM) ( Figure 4 a) and transmission electron microscopy (TEM) ( Figure 4 b) It is observed that the obtained zinc oxide is a one-dimensional nano-dimensional linear product. The dimensions of zinc oxide nanowires vary from 10-150nm, but most of them have dimensions of 50-100nm, the distribution of dimensions is relatively uniform, and the length is 3-8um.

[0024] The leftovers after the reaction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com