Cross linking high density polyethylene pipe

A technology of high-density polyethylene and polyethylene pipes, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of oil pipelines and high-temperature pipelines that are prone to high-temperature softening, interspersed repairs of old pipelines, etc. Excellent chemical medium, performance improvement, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the present invention adopts the preparation processing of following each component raw material through common polyethylene pipe production technology: HDPE high-density polyethylene resin 100 kilograms, CPE modified resin 20 kilograms, dibutyl ester plasticizer 2 kilograms, 0.5 kg of sulfurized bisphenol antioxidant, 2 kg of diethylsiloxane crosslinking agent, and 1 kg of silanol accelerator.

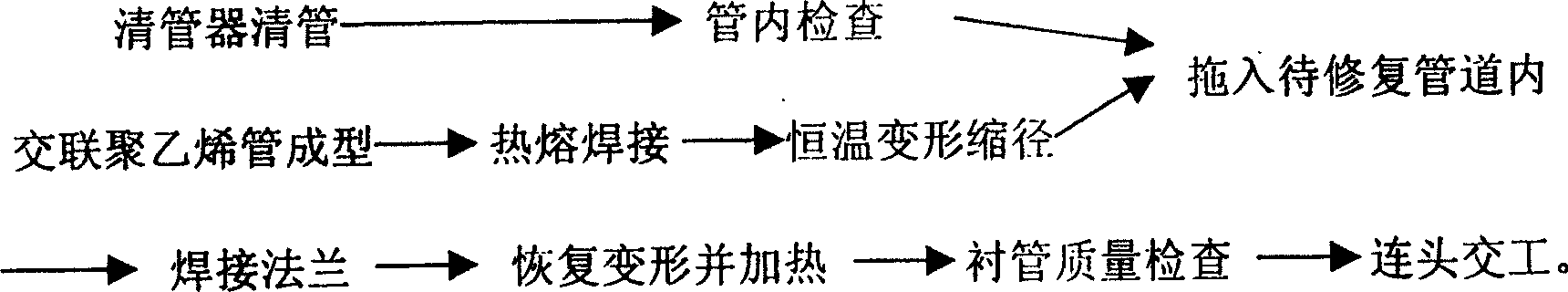

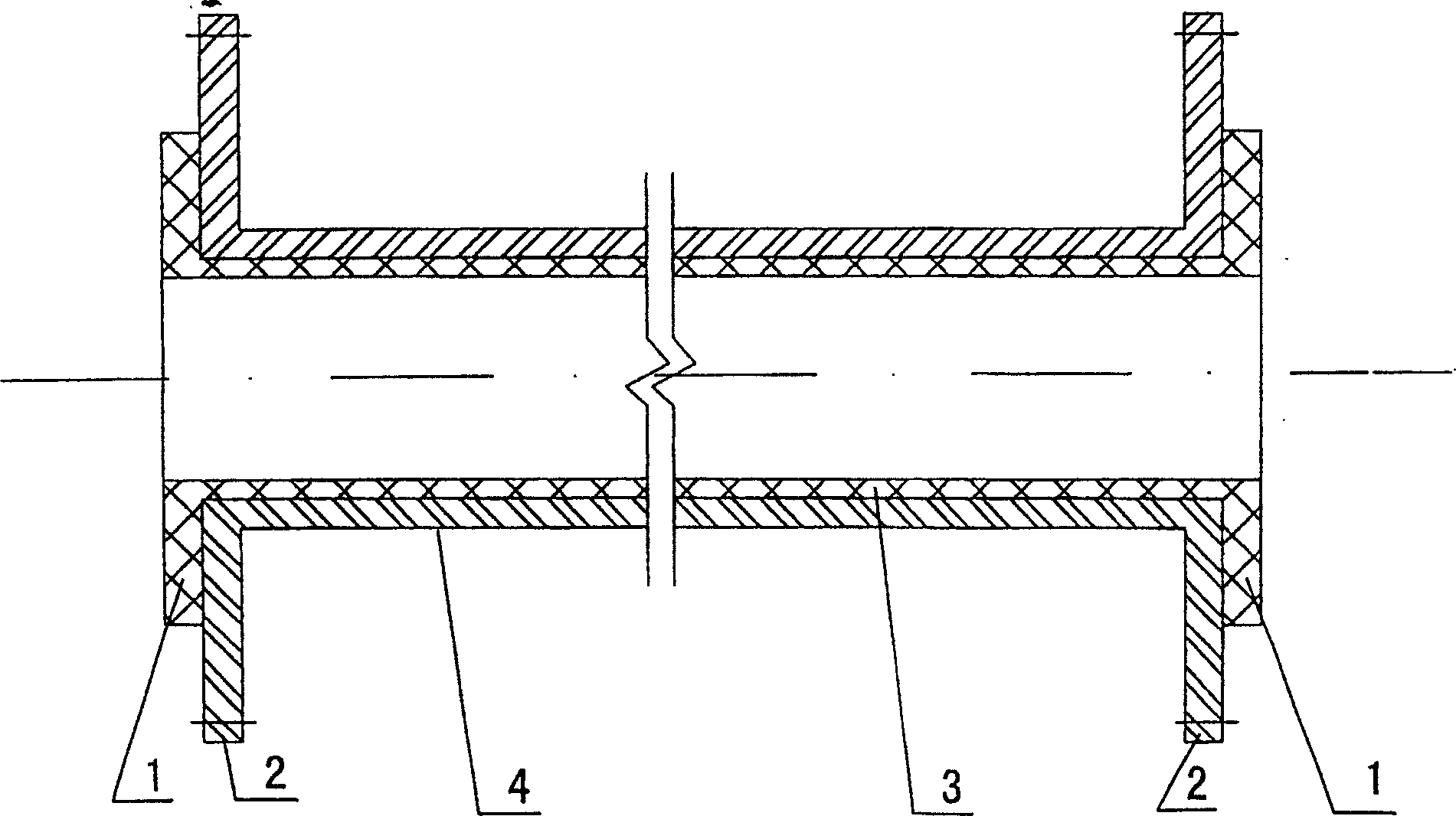

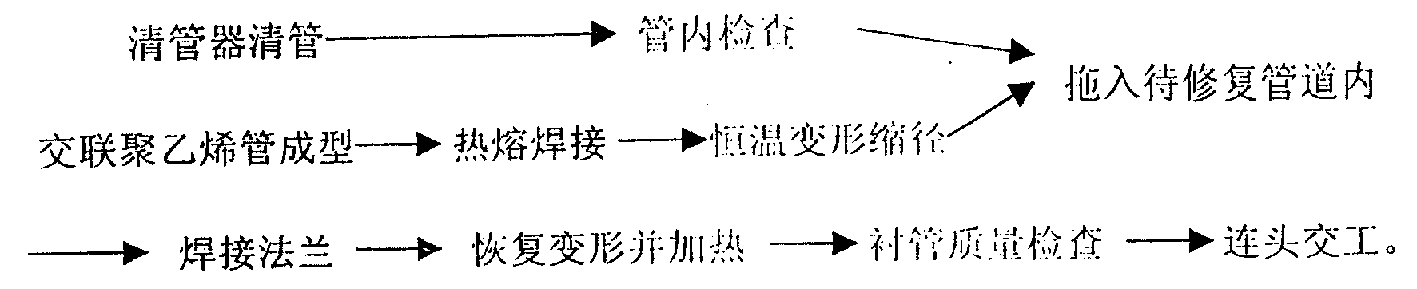

[0027] Such as figure 1 , 2 As shown, the Φ188×6 cross-linked HDPE pipe 3 produced by the present invention according to the above formula is interspersed to repair the Φ219×18 water injection pipe 4. The specific construction process is as follows:

[0028] Step 1: Survey the construction site, detect the direction of the pipeline, find out the pipeline accessories, determine the construction area, dig the operation pit, and weld the flange 2 on the pipeline mouth;

[0029] Step 2: Use a pig to pig the old pipeline 4 to remove the dirt and obstacles in the pipe...

Embodiment 2

[0041] Embodiment 2: the present invention adopts the preparation and processing of following each component raw material through common polyethylene pipe production technology: HDPE high-density polyethylene resin 100 kilograms, CPE modified resin 50 kilograms, dibutyl ester plasticizer 10 kilograms, 8 kg of sulfurized bisphenol antioxidants, 20 kg of diethylsiloxane crosslinking agents, and 10 kg of silanol accelerators.

[0042] The Φ154×5 cross-linked HDPE pipe produced according to the above formula is interspersed to repair the Φ159×6 high water content crude oil pipeline. The specific construction process is as follows:

[0043] The first step: survey the construction site, detect the direction of the pipeline, find out the pipeline accessories, determine the construction area, dig the operation pit, and weld the flange on the pipeline mouth;

[0044] Step 2: Use a pig to clean the old pipeline, remove the dirt and obstacles in the pipeline, and ensure the inner surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com