Polymer and curable composition

A composition and polymer technology, applied in the direction of non-polymer organic compound adhesives, hydrocarbon copolymer adhesives, monocarboxylic acid ester copolymer adhesives, etc., can solve the limitations and sacrifice pressure-sensitive adhesives Agent performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

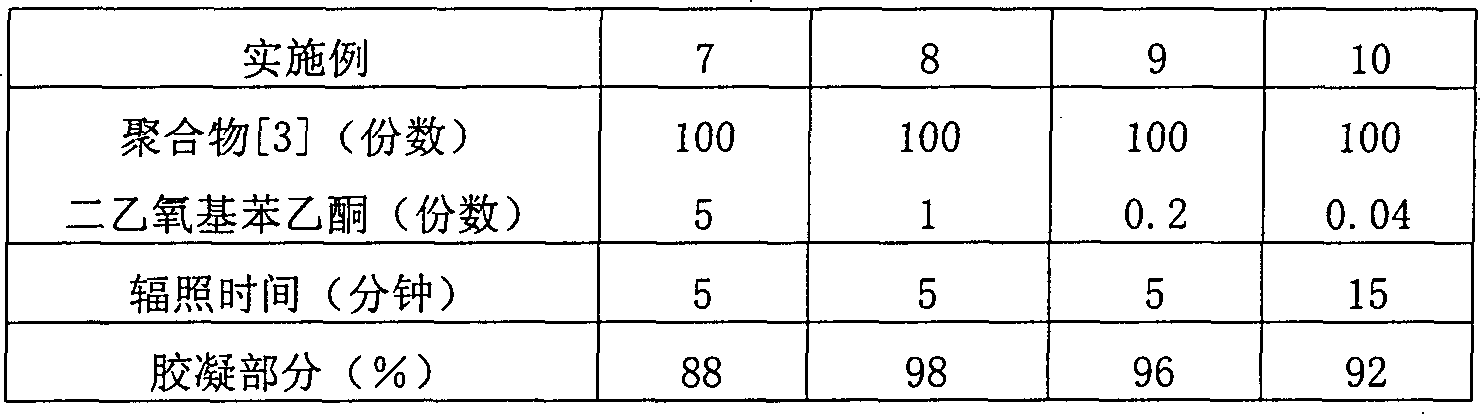

Examples

Embodiment 1

[0271] (embodiment 1) (synthetic potassium methacrylate)

[0272] Methanol (800 mL) cooled to 0°C was added to the flask. Potassium tert-butoxide (130 g) was added in portions. Keeping the mixture at 0°C, a methanol solution of methacrylic acid (100 g) was added dropwise. After the dropwise addition, the temperature of the reaction system was raised from 0°C to room temperature, and the volatile part in the reaction mixture was distilled off under reduced pressure, and potassium methacrylate of the following formula (hereinafter referred to as compound (1)], CH 2 =C(CH 3 )CO 2 K.

Embodiment 2

[0273] (embodiment 2) (synthetic potassium acrylate)

[0274] Methanol (500 mL) cooled to 0°C was added to the flask. Potassium tert-butoxide (78 g) was added portionwise. Keeping the mixture at 0°C, a solution of acrylic acid in methanol (50 g) was added dropwise. After the dropwise addition, the temperature of the reaction system was raised from 0°C to room temperature, and the volatile part in the reaction mixture was distilled off under reduced pressure, and potassium acrylate of the following formula [hereinafter referred to as compound (2)], CH 2 =CHCO 2 K.

Embodiment 3

[0275] (Example 3) (synthesis of poly(n-butyl acrylate) end-capped by methacryloyl group)

[0276] Using copper(I) bromide as catalyst, pentamethyldiethylenetriamine as ligand and diethyl 2,5-dibromoadipate as initiator, n-butyl acrylate was polymerized to obtain number average molecular weight A bromine-terminated n-butyl acrylate polymer of 10900 and a ratio of molecular weight distribution [Mw / Mn] = 1.12 (hereinafter referred to as polymer [1]). 20.0 g of the above polymer [1] was dissolved in N,N-dimethylacetamide followed by the addition of 1.46 g of compound (1), and the mixture was stirred at room temperature for 2 days. The reaction mixture was diluted with ethyl acetate (50 mL), and the insoluble portion was removed by filtration. The filtrate was further diluted with ethyl acetate (150 mL), washed with water and brine. use Na 2 SO 4 The organic layer was dried, and the volatile portion was distilled off under reduced pressure to obtain methacryloyl-terminated pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com