Composition containing semicrystalized polymer gelled liquid fatty phase

A semi-crystalline polymer and composition technology, which can be used in pharmaceutical combinations, medical preparations containing active ingredients, and fat generation, etc., can solve the problems of lack of gloss of the composition, uncomfortable feeling of use of the composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

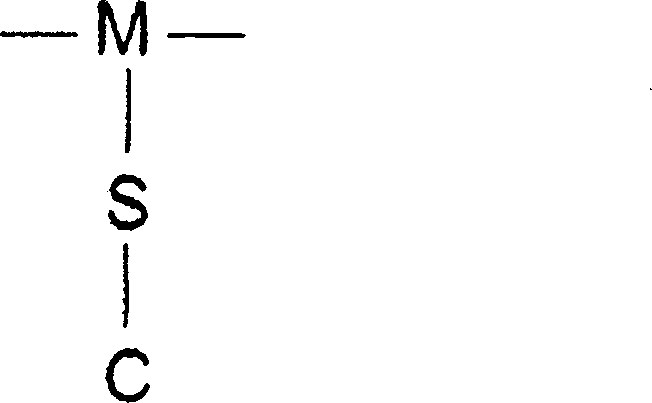

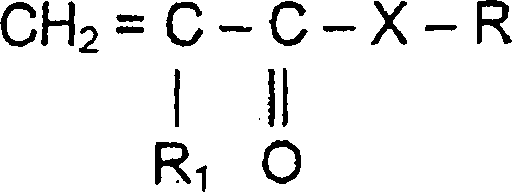

Method used

Image

Examples

Embodiment 1

[0150] Example 1: Acidic polymer with a melting point of 40°C

[0151] 120g Parleam was added to a 1-liter reactor equipped with a central anchor stirrer, reflux condenser and thermometer, and heated from room temperature to 80°C over 45 minutes. Add the following mixture C after 2 hours at 80℃ 1 : 40g cyclohexane+4g Triganox 141 [2,5-bis(2-ethylhexanoylperoxy)-2,5-dimethylhexane]. After 30 minutes, in mixture C 1 Add to mixture C after 1 hour and 30 minutes 2 , Its composition is as follows: 190g stearyl acrylate+10g acrylic acid+400g cyclohexane. After the two were added, the reaction mixture was allowed to continue to act at 80°C for 3 hours, and then all cyclohexane in the reaction mixture was distilled off under normal pressure. Then a polymer containing 60% by weight of active ingredient in Parleam is obtained. Its weight average molecular weight M w It is 35000, characterized by polystyrene equivalent, and its melting temperature M.t. is 40℃±1℃, measured by D.S.C.

Embodiment 2

[0152] Example 2: Basic polymer with a melting point of 38°C

Embodiment 3

[0154] Example 3: Acidic polymer with a melting point of 60°C

[0155] The same procedure as in Example 1 was applied, but instead of stearyl acrylate, behenyl acrylate was used. The resulting polymer is 60% by weight of the active ingredient present in Parleam, and its weight average molecular weight is M w It is 42000, and the melting point M.t. is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com