Method for promoting high-density polyethylene /carbon ink composite material positive temperature coefficient property

A high-density polyethylene, positive temperature coefficient technology, applied in the direction of chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of high cost, high environmental atmosphere requirements, high PTC strength, etc., to achieve cost Low cost, no pollution to the environment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

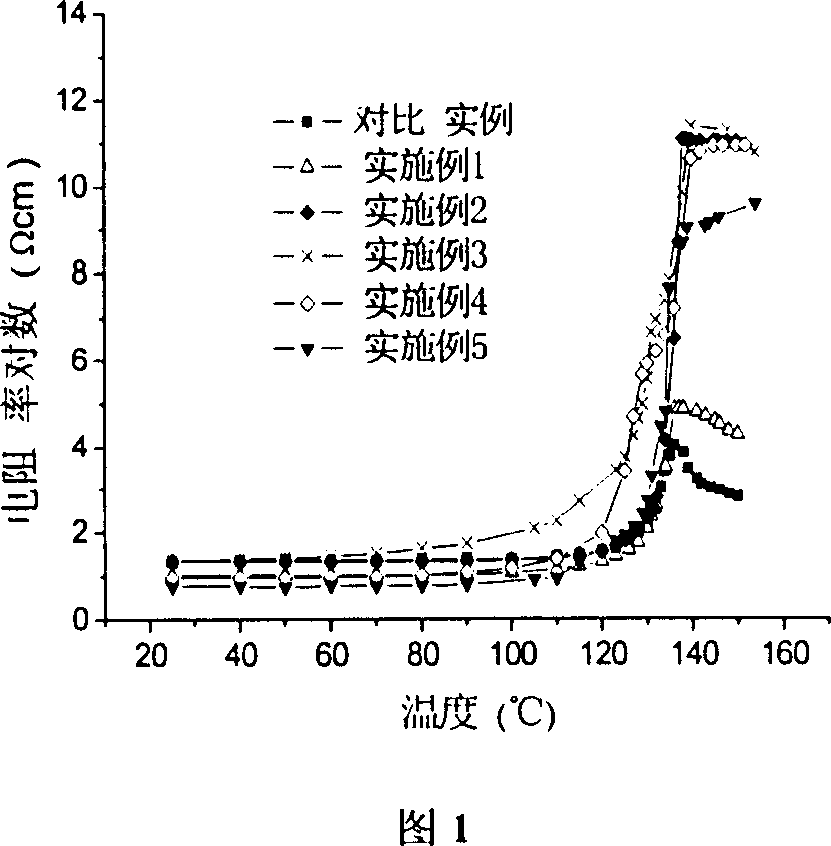

Embodiment 1

[0023] Example 1: The HDPE powder was irradiated with a dose rate of 1kGy / h and a dose of 5kGy to obtain γ-HDPE, then take 100g of γ-HDPE, 36g of untreated CB, 0.3g of antioxidant 1010 and antioxidant 168, Put it into an open mixer for mixing, the mixing temperature is 150-160°C, and the mixing time is 10-15min. The obtained compound is compression molded into a 2mm thick sheet with a flat vulcanizer, and the molding temperature is 175-185 °C, the molding pressure is 10-15MPa, and then the surface of the prepared sheet is heated to 140-160 °C to press into the copper electrode sheet.

Embodiment 2

[0024] Example 2: HDPE is irradiated with a dose rate of 0.1kGy / h and a dose of 10kGy to obtain γ-HDPE, then take 100g of γ-HDPE, 40g of untreated CB, 0.5g of antioxidant 1010 and antioxidant 168 are added to Mixing is carried out in an open mill, the mixing temperature is 150-160°C, and the mixing time is 10-15min. The obtained compound is compression molded into a 2mm thick sheet with a flat vulcanizer, and the molding temperature is 175-185°C. The molding pressure is 10-15MPa, and then the surface of the prepared sheet is heated to 140-160°C and pressed into the copper electrode sheet.

Embodiment 3

[0025] Example 3: The HDPE powder was irradiated with a dose rate of 1kGy / h and a dose of 5kGy to obtain γ-HDPE, and the carbon black was placed in an ozone reactor and treated for 30min at 60°C with an ozone concentration of 11mg / L to obtain o -CB, then take 100g of γ-HDPE, 42g of o-CB, 0.5g of antioxidant 1010 and antioxidant 168, and add them to the open mixer for mixing. The mixing temperature is 150-160°C, and the mixing time is 10-15min, the obtained compound is compression molded into a 2mm thick sheet with a flat vulcanizer, the molding temperature is 175-185°C, the molding pressure is 10-15MPa, and then the surface of the obtained sheet is heated to 140-160 Press into the copper electrode sheet at ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com