Manufacturing method and application of single wall carbon nano tube

A technology of single-walled carbon nanotubes and nanotubes, which is applied in the surface field, can solve the problems of uncontrolled spatial helicity and diameter, and no ordered arrays are produced, achieving the effect of high order degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following, various embodiments of the present invention are described.

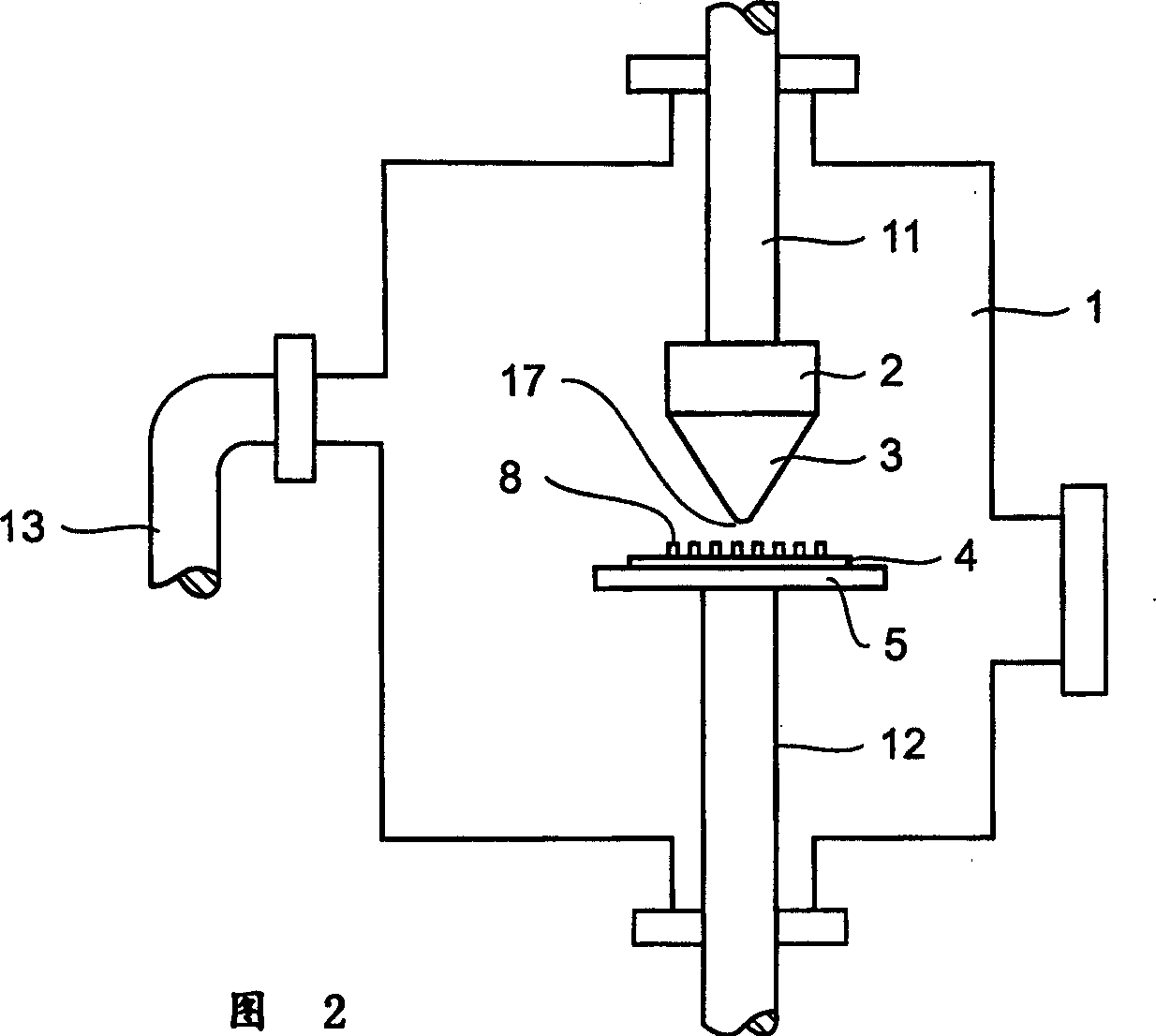

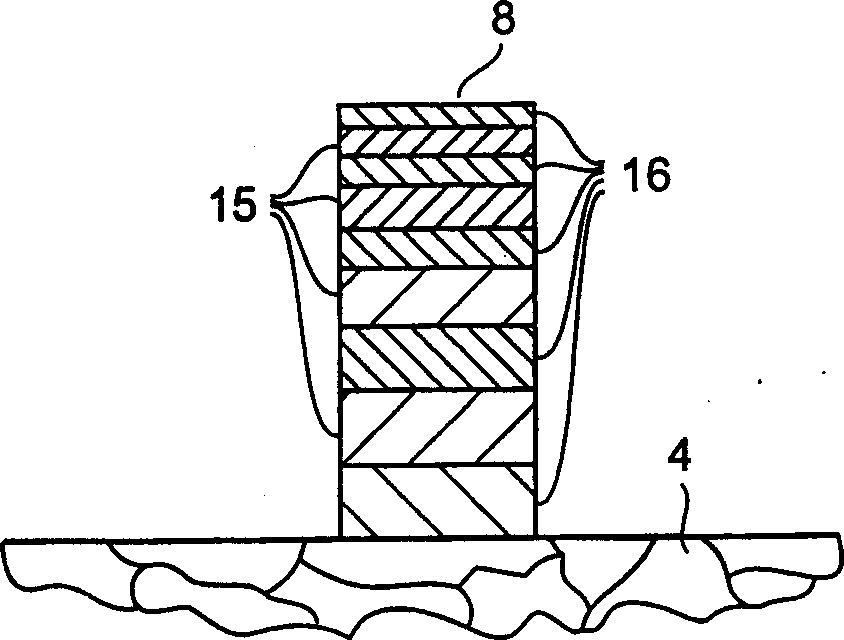

[0031] The method used to fabricate single-walled carbon nanotube crystals involves nanoscale patterning of a solid matrix material. Fullerene (here C 60 molecules) and a controlled mixture of nickel as a catalyst evaporates onto a molybdenum substrate. The resulting structure is then pyrolyzed in vacuum in the presence of a magnetic field. A combination of electron diffraction studies and electron energy loss spectroscopy (EELS) confirmed that the resulting structures are nearly perfect columnar crystals of single-walled carbon nanotubes oriented perpendicular to the substrate surface.

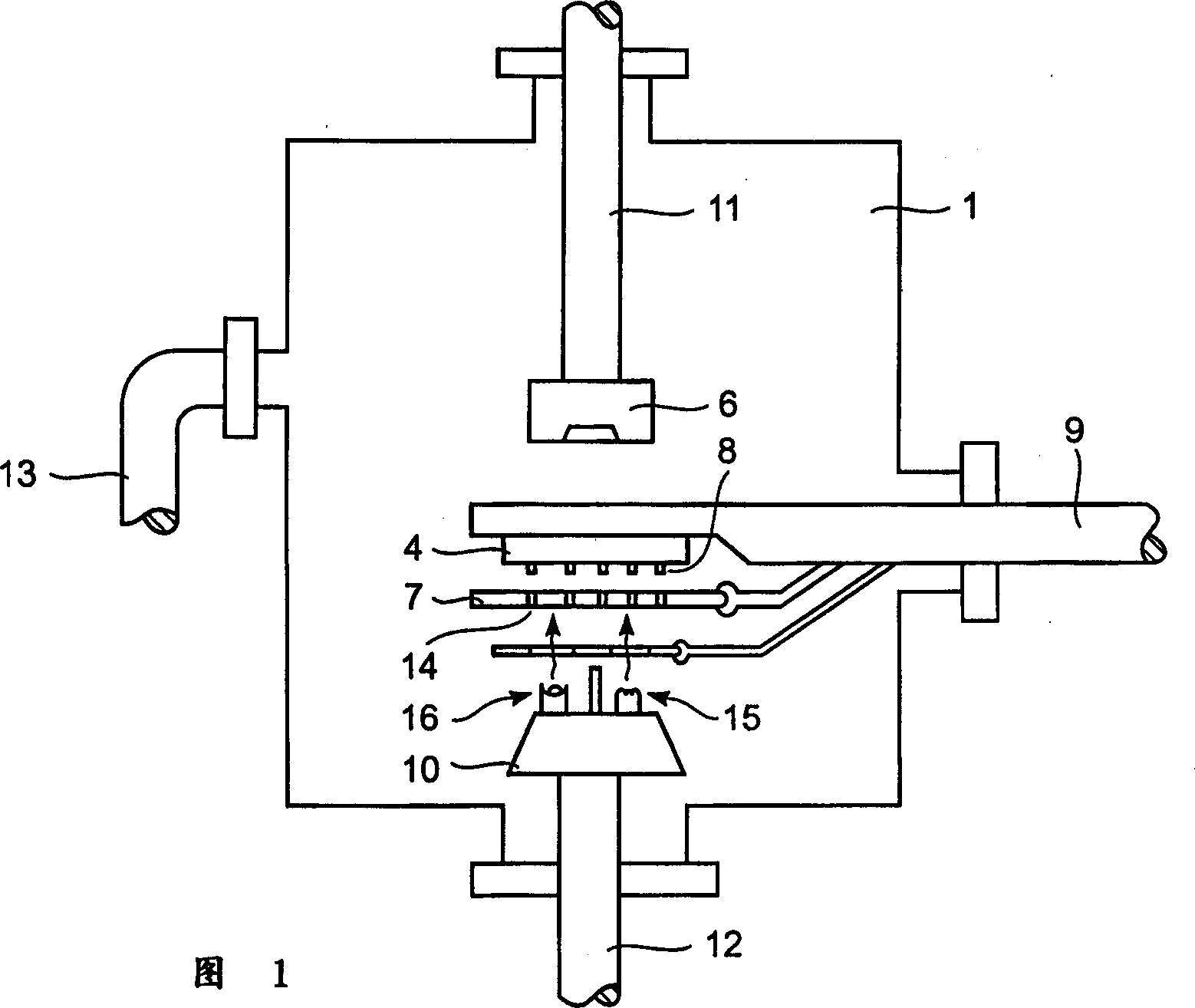

[0032] A first schematic diagram of an apparatus for manufacturing single-walled carbon nanotubes is shown in FIG. 1 .

[0033] The reaction chamber 1 comprises four openings, a first opening through which is passed a sample holder 9 for holding a substrate 4 and a patterned evaporation template 7, also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com