Copper base catalyst for catalyzing wet oxidation method treating industrial waste water

A copper-based catalyst, industrial wastewater technology, applied in oxidation water/sewage treatment, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation (I) of catalyst

[0028] Take 550ml of Na with a concentration of 1.0mol / L 2 CO 3 The solution was placed in a water bath with a water bath temperature of 70° C. and heated for 20 minutes. Take 1.0mol / L Cu(NO 3 ) 2 Solution 100ml, 1.0mol / L Zn(NO 3 ) 2 Solution 110ml, take 0.5mol / L of AL 2 (NO 3 ) 3 Solution 75ml, transferred to a beaker, mixed evenly, slowly added dropwise to the Na 2 CO 3 solution in a beaker while stirring rapidly. After the titration, ensure that the pH of the mother solution is ≥ 9, and let the precipitate and the mother solution age together for a day and night.

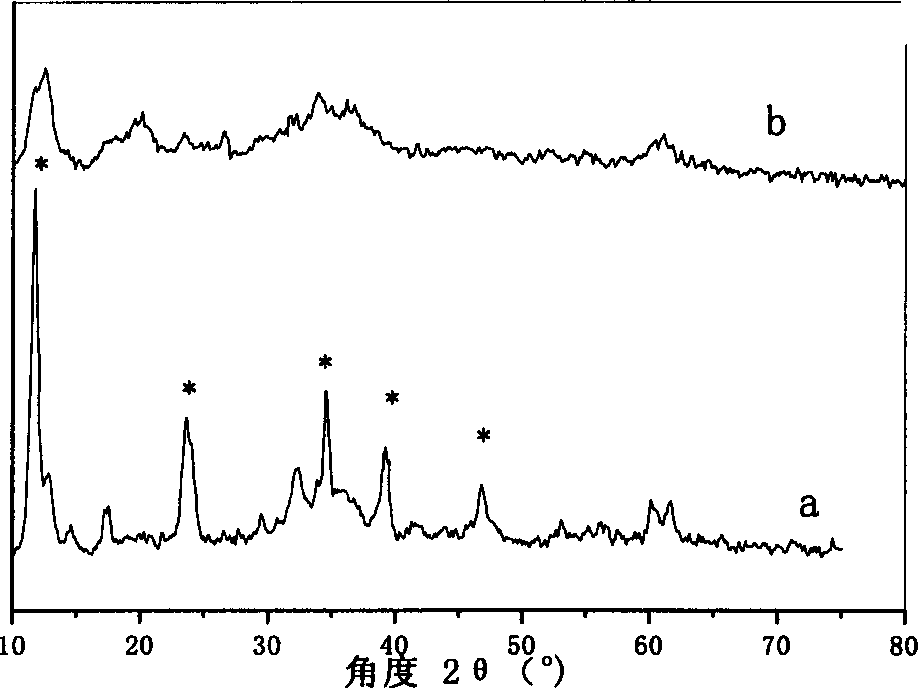

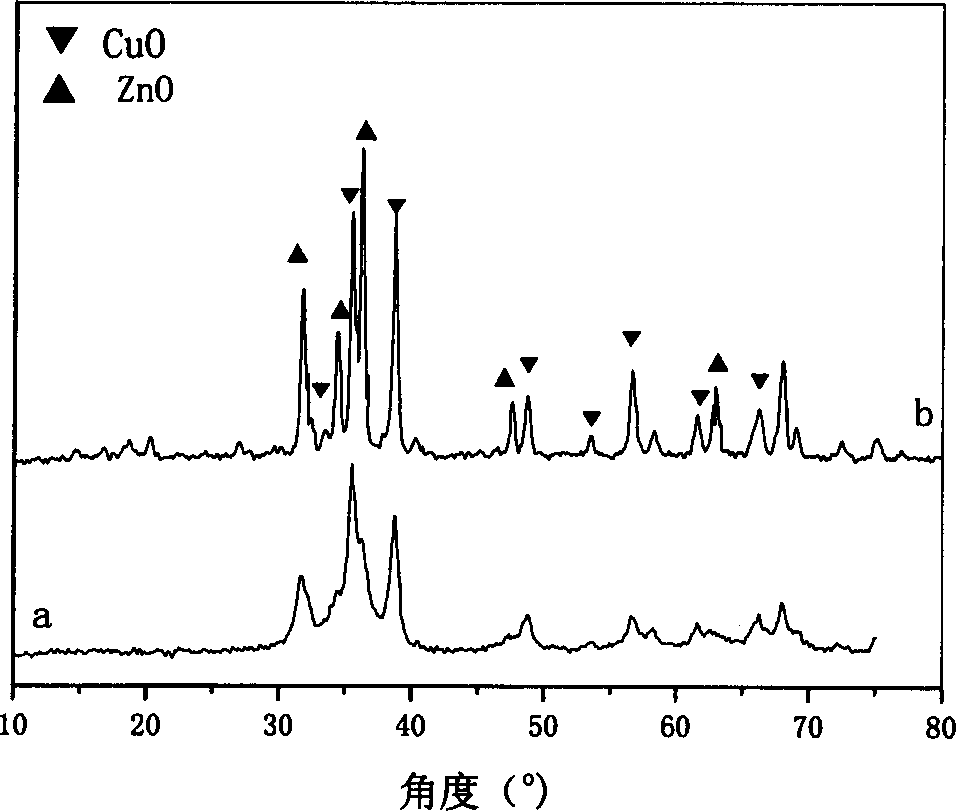

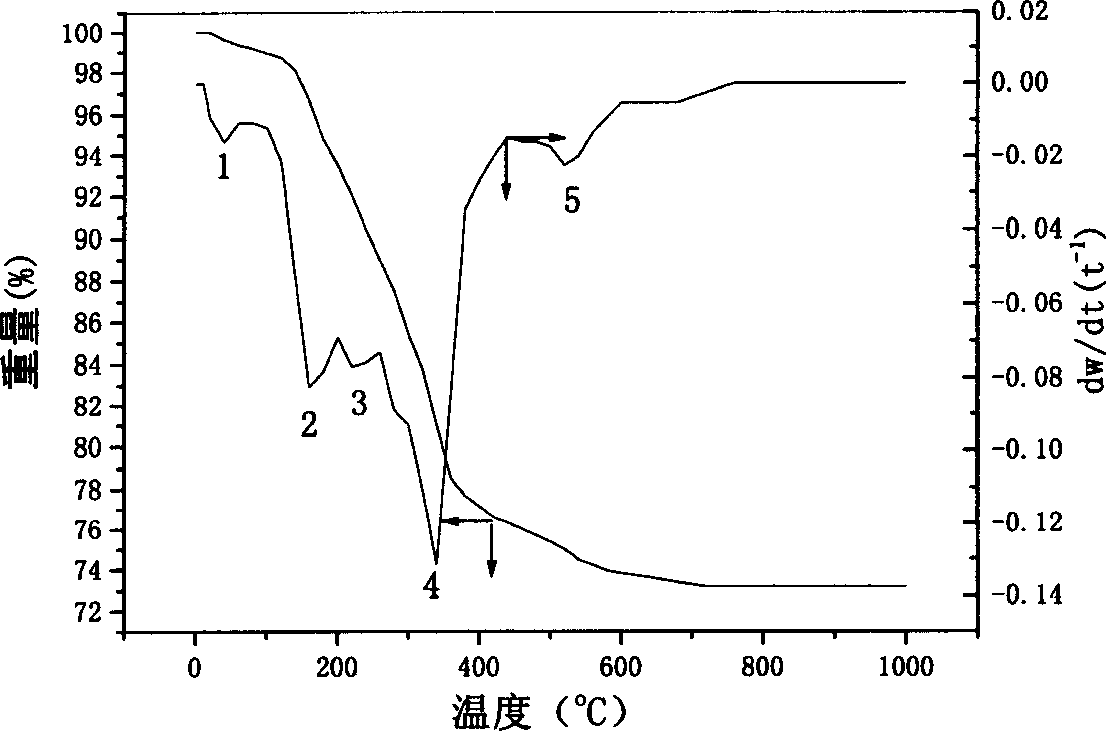

[0029]After aging, use vacuum filtration to separate the precipitate from the mother liquor, and wash with deionized water four times under the condition of vacuum filtration to remove impurity ions. Squeeze the precipitate into a Φ3 strip, dry it in the air, and then dry it at 110°C for 2 hours to obtain a dry precipitate for use. Its XDR spectru...

Embodiment 2

[0031] Embodiment 2: the preparation of catalyst (II)

[0032] Take 560ml of Na with a concentration of 1.0mol / L 2 CO 3 Solution replaces the Na of 550ml among the embodiment 1 2 CO 3 solution, and weigh La 2 (NO 3 ) 3 .nH 2 O crystal 1.0g, Ce(NO 3 ) 3 ·6H 2 1.14 g of O crystals were dissolved in the mixed salt solution, and other conditions were the same as in Example 1 to prepare catalyst B.

Embodiment 3

[0033] Embodiment 3: the preparation of catalyst (III)

[0034] Take 700ml of Na with a concentration of 1.0mol / L 2 CO 3 Solution replaces the Na of 550ml among the embodiment 1 2 CO 3 solution, take 1.0mol / L of Mg(NO 3 ) 2 Solution 130ml replaces 1.0mol / L of Zn(NO 3 ) 2 Solution 110ml, take 0.5mol / L Cr 2 (NO 3 ) 3 Solution 120ml instead of 0.5mol / L Al 2 (NO 3 ) 3 Solution 75ml, calcination temperature is 600 ℃ and processing time is 10 hours, other conditions are the same as embodiment 1, can prepare catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com