Photoinduction SiO2 gel preparation and microfine pattern making method thereof

A technology for the preparation of fine graphics and thin films, which is applied in the production of optical splitters, grooved substrates, and optical diffraction components such as gratings. The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

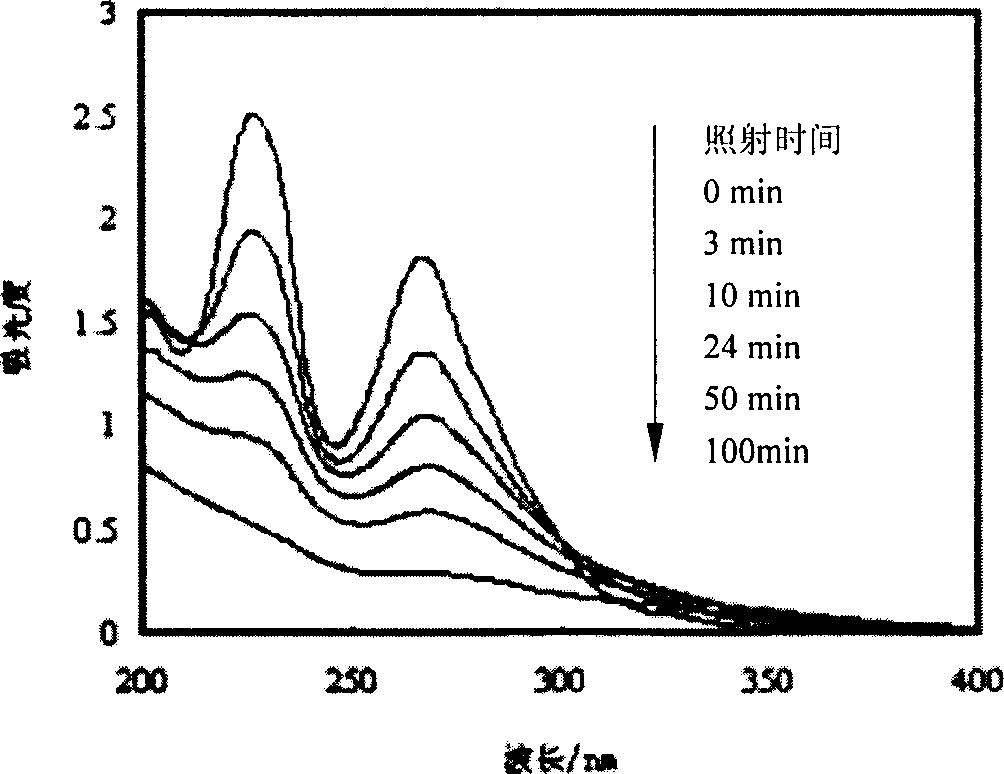

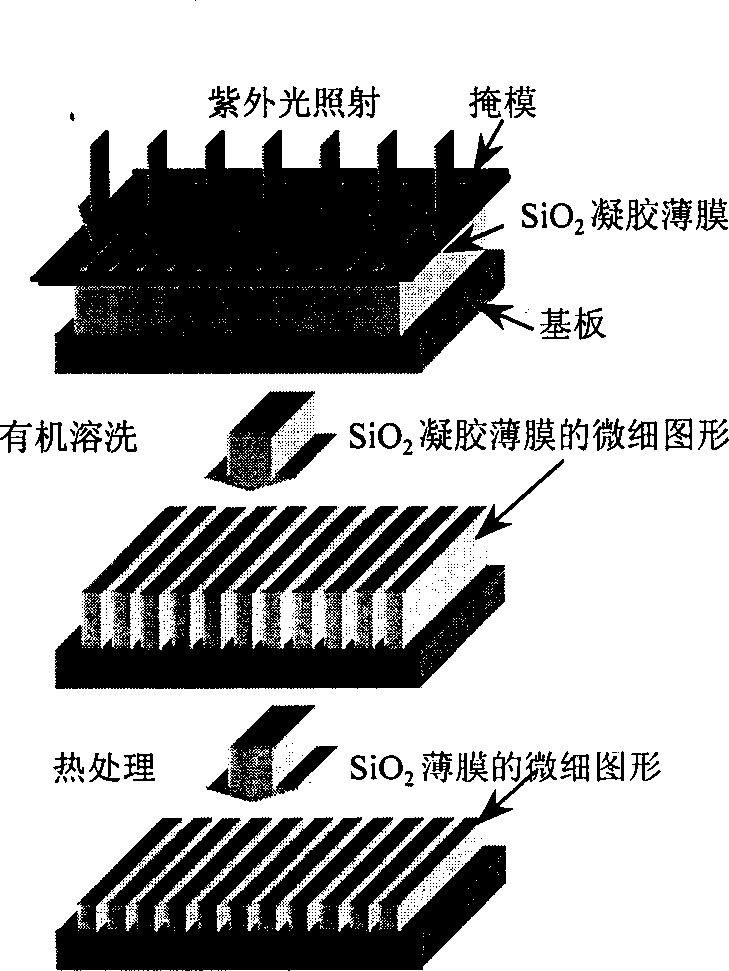

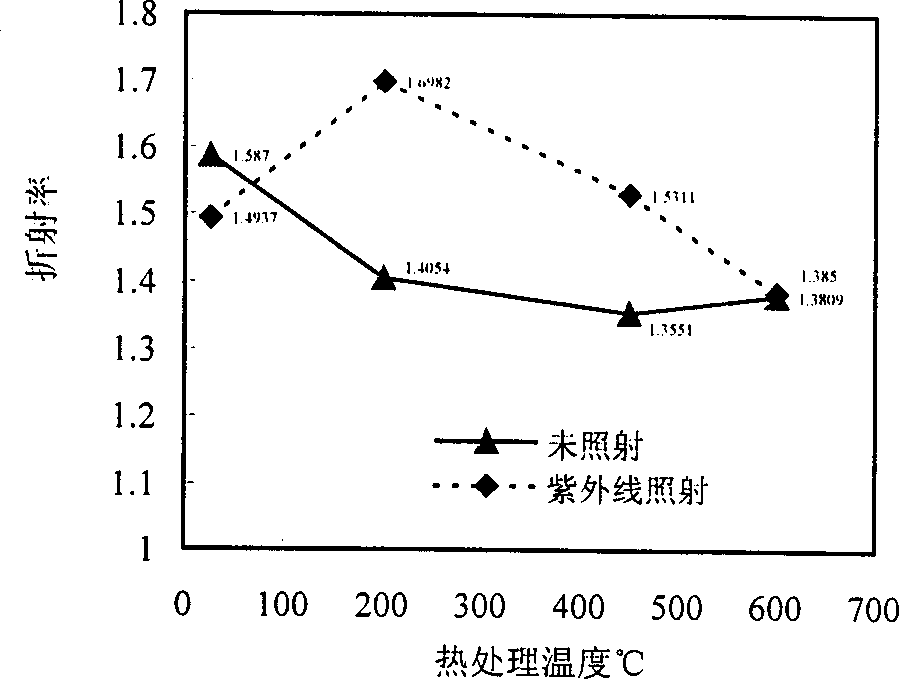

[0034] Example 1: see Figure 1~3 , the photosensitive SiO of the present invention 2 Gel thin film preparation and its fine pattern making method are carried out as follows: (1) photosensitive SiO 2 Sol preparation

[0035] Firstly, the photosensitive sol is prepared by chemical modification method, and the components and proportions of the sol are as follows:

[0036] TEOS:H 2 O:HCl:EeOH:Ph=1:4:0.05:20:0.5

[0037] TEOS:---Ethyl Orthosilicate (Si(OC 2 h 5 ) 4 ) to generate SiO 2 basic raw material

[0038] EeOH:----ethanol (C 2 h 5 OH) solvent

[0039] Ph:---Philoline (C 12 h 8 N 2) Chemical modifiers that form photosensitive chelates

[0040] h 2 O---water is the basic raw material for water addition reaction with TEOS

[0041] HCl---hydrochloric acid is a catalyst to accelerate the reaction.

[0042] After mixing and stirring the chemical reagents of the above components for 4 hours, a uniform and transparent sol can be obtained. (2) SiO 2 Film preparat...

Embodiment 2

[0048] Embodiment 2: The difference between this embodiment and 1 is that the photosensitive SiO 2 When the sol is prepared, the composition and proportion of the sol change, namely:

[0049] TEOS:H 2 O:HCl:EeOH:Ph=1:3:0.1:30:1

[0050] TEOS:---Ethyl Orthosilicate (Si(OC 2 h 5 ) 4 ) is the basic raw material to generate SiO2

[0051] EeOH:----ethanol (C 2 h 5 OH) solvent

[0052] Ph:---Philoline (C 12 h 8 N 2 ) Chemical modifiers that form photosensitive chelates

[0053] h 2 O---water is the basic raw material for water addition reaction with TEOS

[0054] HCl---hydrochloric acid is a catalyst to accelerate the reaction.

[0055] Others are all the same as embodiment 1, and the purpose of embodiment 1 can be reached equally.

Embodiment 3

[0056] Embodiment 3: The difference between this embodiment and 1 is that the photosensitive SiO 2 When the sol is prepared, the composition and proportion of the sol change, namely:

[0057] TEOS:H 2 O:HCl:EeOH:Ph=1:2:0.2:40:2

[0058] TEOS:---Ethyl Orthosilicate (Si(OC 2 h 5 ) 4 ) is the basic raw material to generate SiO2

[0059] EeOH:----ethanol (C 2 h 5 OH) solvent

[0060] Ph:---Philoline (C 12 h 8 N 2 ) Chemical modifiers that form photosensitive chelates

[0061] h 2 O---Water reacts with TEOS to generate raw materials

[0062] HCl---hydrochloric acid is a catalyst to accelerate the reaction.

[0063] Others are all the same as embodiment 1, and the purpose of embodiment 1 can be reached equally.

[0064] Of course, the composition and proportion of its sol can also be adjusted, such as TEOS:H 2 O:HCl:EeOH:Ph=1:2.5:0.15:25:1.5 or TEOS:H 2 O: HCl: EeOH: Ph = 1: 3.5: 0.2: 40: 1, ... within the range described in the technical solution, the purpose of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com