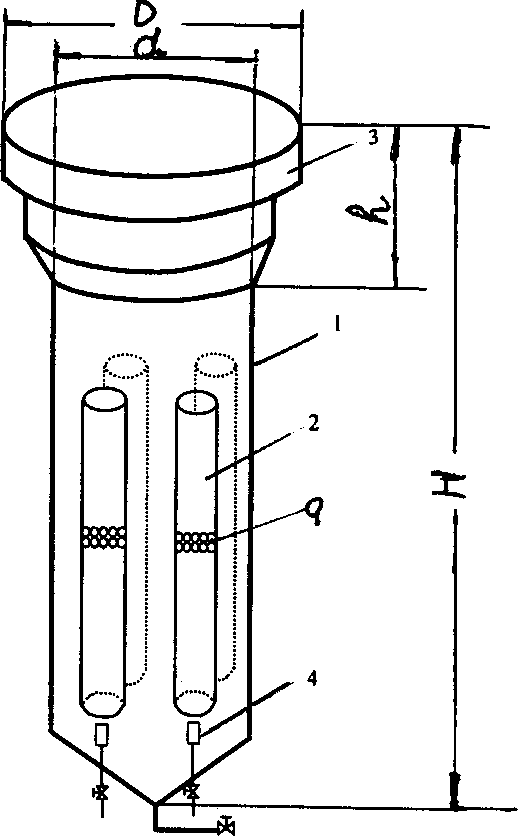

Multi-stage circulating aerating tower

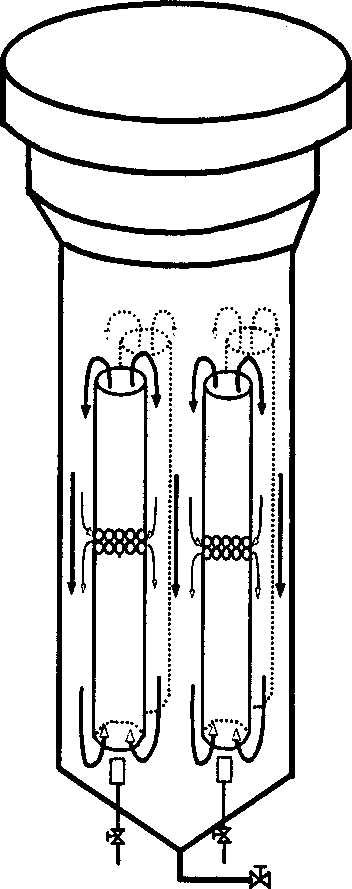

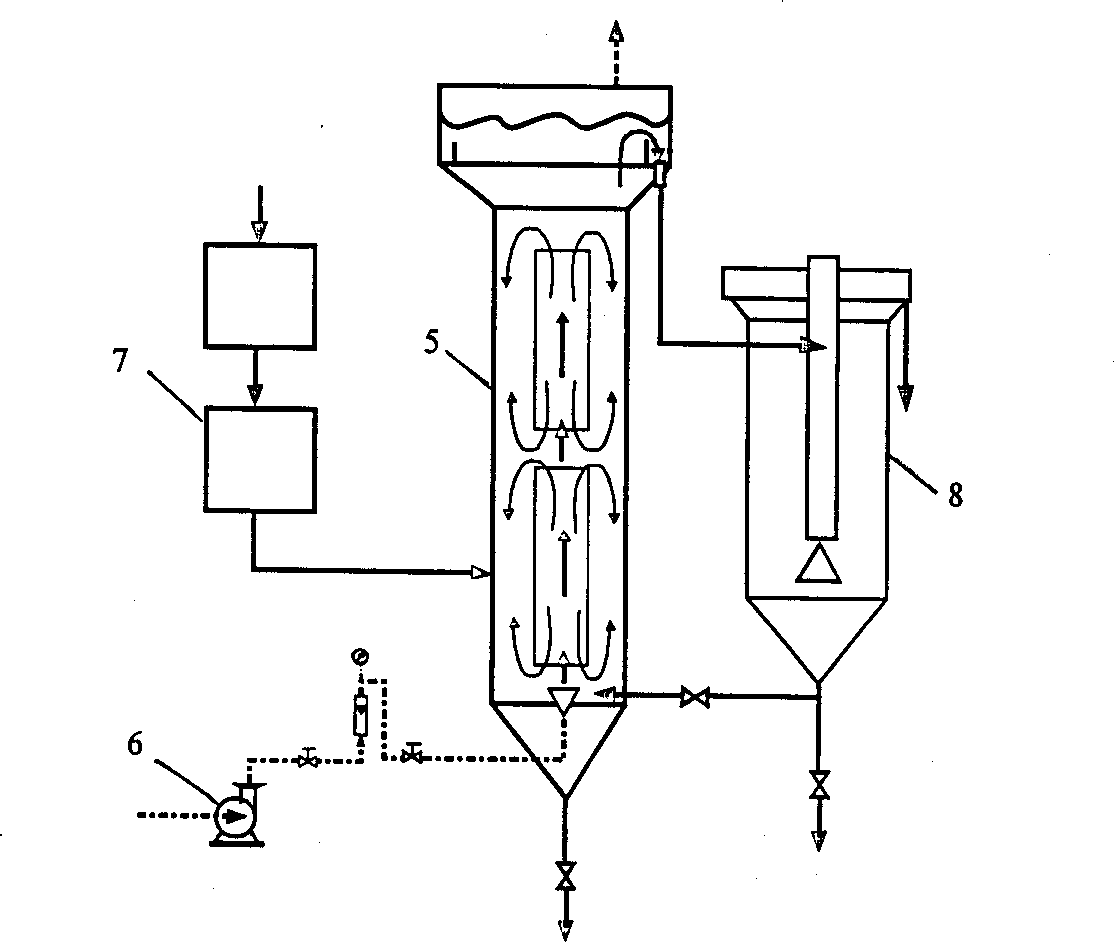

A technology of aeration and aeration head, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. Uneven three-phase mixing and other problems, to achieve the effect of small footprint, reduced footprint and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The circulation aeration tower is made of borosilicate glass, and the inside is equipped with a multi-stage guide tube. Flow tube, sewage is phenol-acetone industrial sewage, mainly contains phenol, acetone, acetophenone and benzyl alcohol, etc., COD is 1000mg / l, adopts continuous operation at room temperature, the concentration of activated sludge is 3-6g / l, sewage The residence time in the tower is 4-6 hours. The COD of the treated water is reduced to 122-166, and the COD removal rate is 83.4-87.8%.

Embodiment 2

[0025] Embodiment 2: the circulation aeration tower is the same as embodiment 1, the sewage is polyolefin catalyst workshop sewage, COD is 1000mg / l, adopts continuous operation under room temperature, the concentration of activated sludge is 3-6g / l, the sewage in the tower The residence time is 2-4 hours. The COD of the treated water is reduced to 50-60. The COD removal rate is 94-95%.

Embodiment 3

[0026] Embodiment 3: The size of the multi-stage circulation aeration tower is: the height of the tower is 1.5 meters, the diameter of the tower body is 15 centimeters, a guide tube is arranged inside, the sewage is petrochemical comprehensive wastewater, and the COD is 1000 mg / l. Continuous operation at room temperature, the concentration of activated sludge is 3g / l, and the residence time of sewage in the tower is 6 hours. The COD of the treated water is reduced to 200. COD removal rate is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com