Process for preparing internally degradable tubular liver tissue frame material

A technology of frame material and liver tissue, which is applied in the field of three-dimensional liver tissue frame materials, can solve the problems of material exchange, nutrients cannot be replenished, and metabolic waste cannot be discharged in time, so as to achieve the effect of prolonging the survival period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

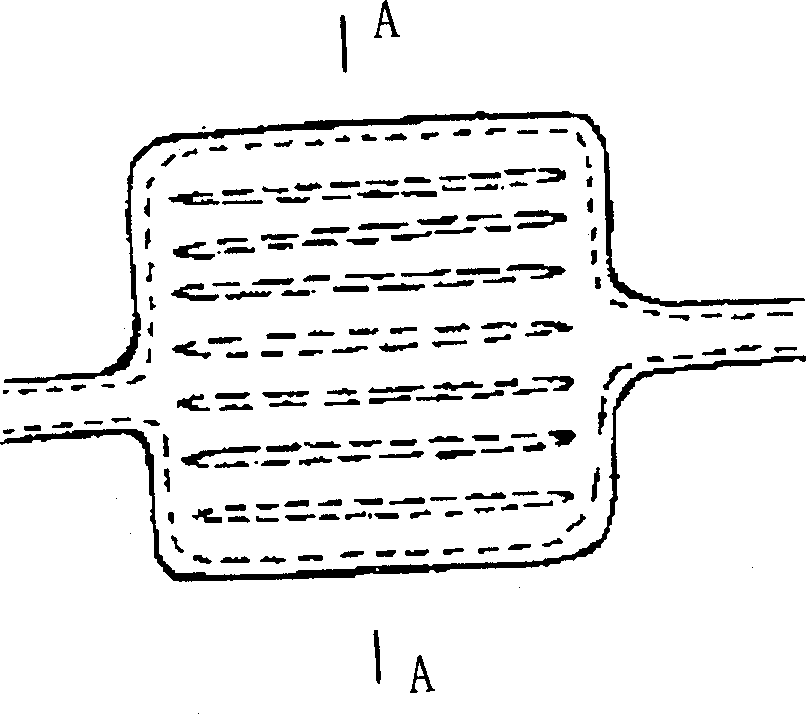

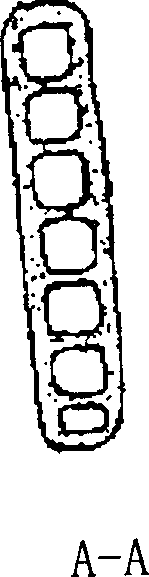

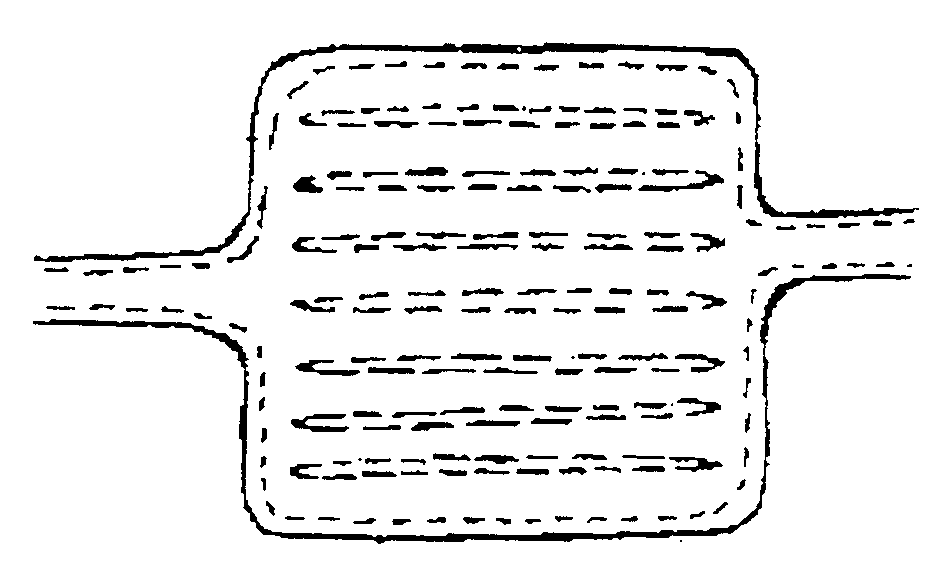

Image

Examples

Embodiment 1

[0036] (1) Heat and mix sliced paraffin wax and stearic acid in a 1:1 (W / W) ratio in a water bath at 60°C to make a blank, and then carve it into a fine mesh mold.

[0037] (2) Dissolve a certain amount of polylactic acid (Mw: 3×10) in 1,4-dioxane to make a solution with a concentration of 5 (W / V)% and add 0.5 (W / V)% The pore-forming agent ammonium bicarbonate is uniformly mixed and coated on the mold in (1), freeze-dried and formed into a film.

[0038] (3) Soak the sample with 0.05M hydrochloric acid to remove the pore-forming agent, and demold it with xylene to prepare a multi-tubular scaffold material with a pore diameter of 50-100 μm and a porosity of 45%.

[0039] (4) After the above sample is activated with 0.5M NaOH solution, the excess sodium hydroxide is neutralized with 0.1mol / L hydrochloric acid solution, and rinsed with deionized water; in 0.5wt% 1-ethyl-3- Soak in (3-dimethylaminopropyl)carbodiimide hydrochloride aqueous solution at 4°C for 12h, use 2-(N-morphol...

Embodiment 2

[0044] (1) Paraffin wax and stearic acid were mixed in a beaker at a ratio of 1.25:1 (W / W) to 65°C to make a blank, and then carved into a fine mesh mold.

[0045] (2) Take a certain amount of polylactic acid and polyglycolic acid copolymer (70:30M / M) and dissolve it in 1,4-dioxane to make a solution with a concentration of 15 (W / V)% and add 0.5 (W / V)% disodium hydrogen phosphate, uniformly mixed and coated on the mold in (1), freeze-dried and film-formed.

[0046] (3) Soak the sample in deionized water to remove the pore-forming agent, and demold it with xylene to prepare a multi-tubular scaffold material with a pore diameter of 80-150 μm and a porosity of 60%.

[0047] (4) After the above sample is activated with 0.75M NaOH solution, the excess sodium hydroxide is neutralized with 0.5mol / L hydrochloric acid solution, and rinsed with deionized water, in 0.75wt% 1-ethyl-3- Soak in (3-dimethylaminopropyl) carbodiimide hydrochloride aqueous solution at 4°C for 24 hours, use 2-(...

Embodiment 3

[0051] (1) Paraffin wax and stearic acid are mixed in a beaker at a ratio of 1.4:1 (W / W) to 70°C to make a blank, and then carved into a fine mesh mold.

[0052] (2) Take a certain amount of polycaprolactone (Mw: 5×10 4 ) was dissolved in 1,4-dioxane to make a solution with a concentration of 25 (W / V)%, and 1 (W / V)% disodium hydrogen phosphate was added, mixed evenly and coated on (1 ) on the mold, freeze-dried and film-formed.

[0053] (3) Soak the sample in deionized water, and demold it with xylene to obtain a multi-tubular scaffold material with a pore diameter of 100-300 μm and a porosity of 75%.

[0054] (4) After the above-mentioned sample is activated with 1M NaOH solution, excessive sodium hydroxide is neutralized with 1mol / L hydrochloric acid solution, and rinsed with deionized water; In dimethylaminopropyl) carbodiimide hydrochloride aqueous solution, soak 36h at 4 ℃, adopt 2-(N-morpholine)-ethane-sulfonic acid as stabilizer, adjust pH=6.0, in 1wt% Chitosan aceti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com