High-energy accumlator with nano active carbone fibres (CNT) electrode

A nano-carbon fiber and battery technology, applied in the direction of active material electrodes, lead-acid batteries, lead-acid battery electrodes, etc., can solve the problems of reducing payload and effective energy consumption, and achieve shortened charging time, reduced weight, and high specific energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

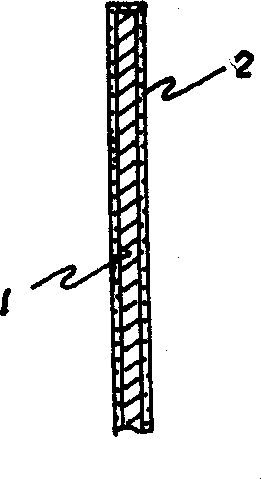

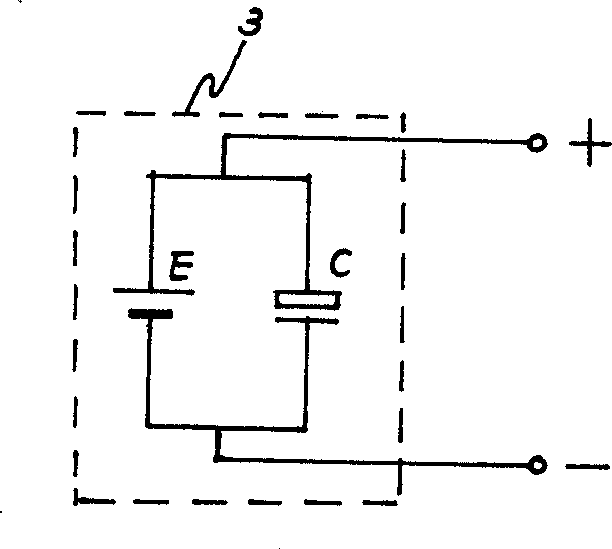

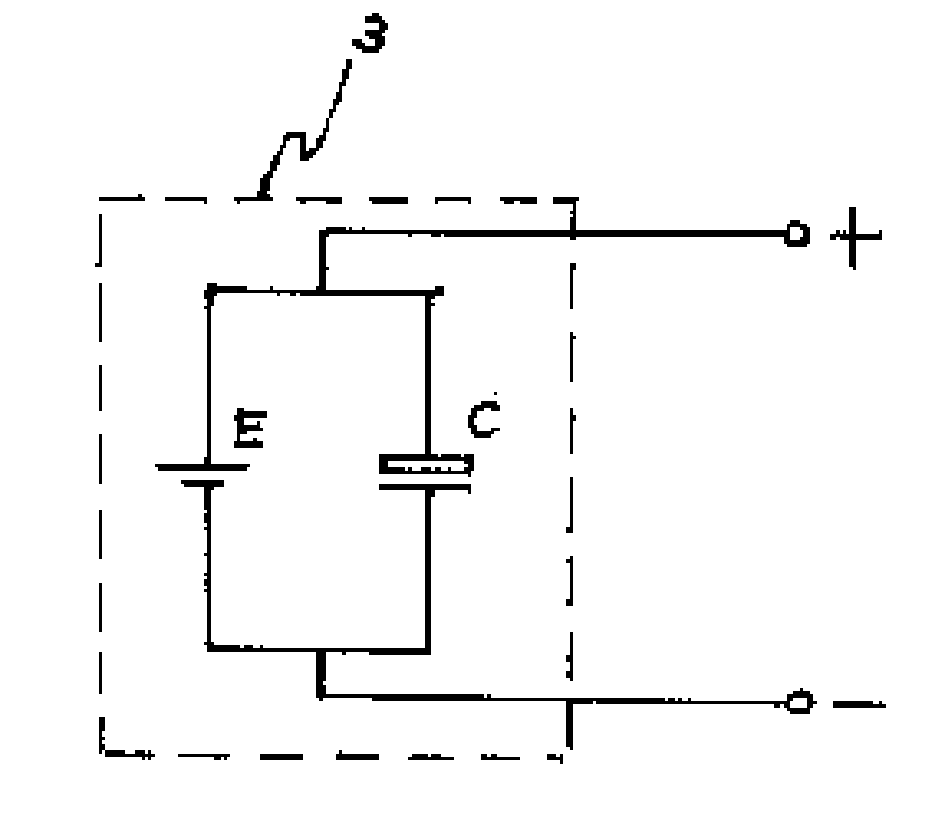

[0018] Embodiment 1. A kind of active carbon nanofiber (CNT) electrode high-energy accumulator. It consists of battery tank, tank cover, electrolyte, positive and negative plates, diaphragm and positive and negative electrodes. The positive plate is composed of an aluminum grid and an active nano-carbon fiber layer, and the negative plate is composed of a copper grid and an active nano-carbon fiber layer. The active carbon nanofibers have a diameter of 20nm and a length of 290nm. Each set of positive and negative plates and their separators have a small spacing that makes them large capacitors. It is equivalent to connecting this large capacitor in parallel with the battery. The diaphragm is made of polymer non-woven fabric with high dielectric strength, and its size is the same as the internal size of the battery tank. It can charge and discharge with high current, and the charging time is shortened to 1 / 17 of the past. The specific energy is as high as 8 times that of co...

Embodiment 2

[0019] Embodiment 2. An active carbon nanofiber (CNT) electrode high-energy storage battery, which belongs to storage battery technology. It consists of battery tank, tank cover, electrolyte, positive and negative plates, diaphragm and positive and negative electrodes. The positive plate is composed of an aluminum grid and an active nano-carbon fiber layer, and the negative plate is composed of a copper grid and an active nano-carbon fiber layer. The active carbon nanofibers have a diameter of 80nm and a length of 300nm. The rest are the same as embodiment 1. It can charge and discharge with high current, and the charging time is shortened to 1 / 10 of the past. The specific energy is up to 7 times that of conventional lead-acid batteries, and the weight is greatly reduced.

Embodiment 3

[0020] Embodiment 3. An active carbon nanofiber (CNT) electrode high-energy storage battery, which belongs to storage battery technology. It consists of battery tank, tank cover, electrolyte, positive and negative plates, diaphragm and positive and negative electrodes. The positive plate is composed of an aluminum grid and an active nano-carbon fiber layer, and the negative plate is composed of a copper grid and an active nano-carbon fiber layer. The active carbon nanofibers have a diameter of 60nm and a length of 200nm. The rest are the same as embodiment 1. It can charge and discharge with high current, and the charging time is shortened to 1 / 20 of the past. The specific energy is as high as 10 times that of conventional lead-acid batteries, and the weight is greatly reduced.

[0021] Embodiments 1 to 3 can be widely used in various fields such as industrial equipment, vehicles, and national defense weapons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com