Fibre for tissue engineering scaffold and making method thereof

A tissue engineering scaffold and fiber technology, applied in the field of biomedical engineering materials, can solve the problems of difficult biodegradation, high price, unfavorable cell attachment, division, proliferation, etc., and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First put 0.6 kg of leftover raw silk (the by-product of cocoon reeling in the silk reeling factory) into 10 liters of sodium carbonate aqueous solution with a concentration of 0.05%, boil for 0.5 hour, repeat the treatment three times, and remove the sericin on the periphery of the silk to obtain pure silk. Silk fibroin.

[0018] The pure silk fibroin after natural drying is dissolved in 1.5 liters of 80% phosphoric acid at a temperature of 30°C for 2 hours, purified by filtration, and ultrasonically defoamed for 1 hour to make a spinning stock solution;

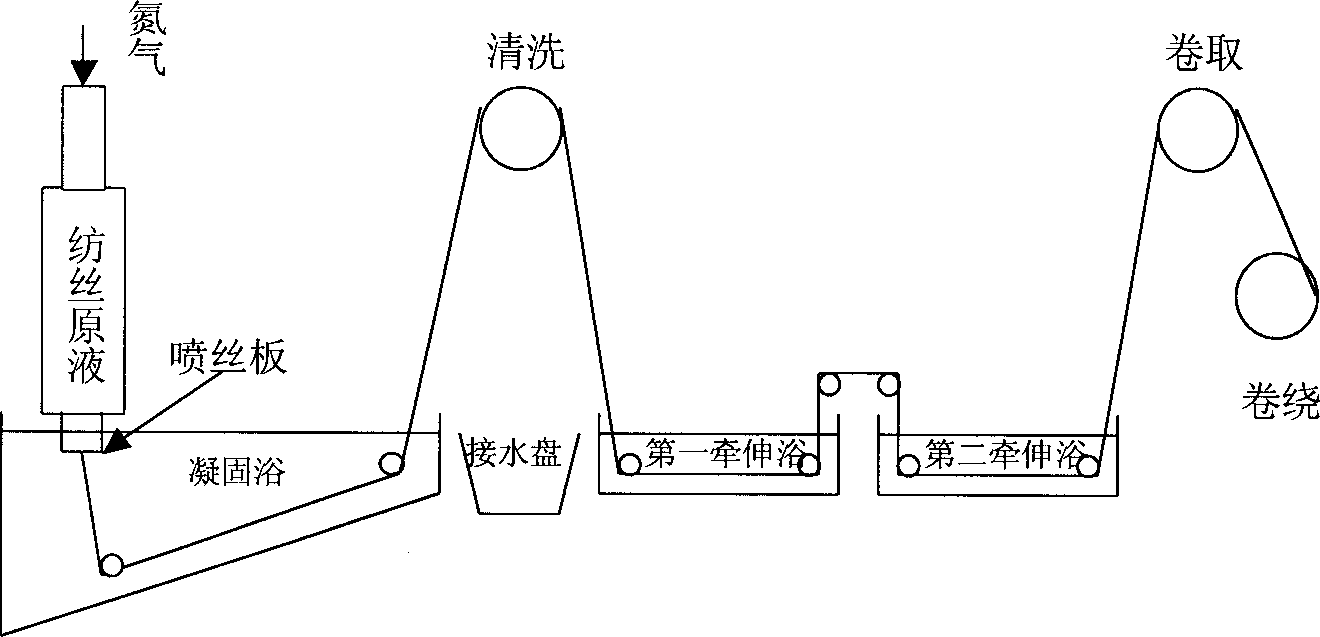

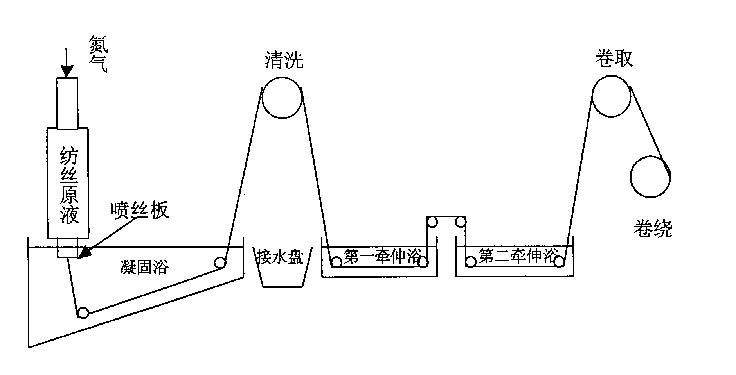

[0019] See attached figure 1 , under the action of 0.4MPa nitrogen, use a spinning hole with a diameter of 0.5mm, and at a temperature of 25°C, spray the silk fibroin spinning stock solution at a speed of 2 grams per minute, and enter the concentration of 25% ammonium sulfate In the coagulation solution, the temperature of the coagulation bath is 30° C., and the primary silk fibroin fibers are coagulated by spinning...

Embodiment 2

[0022] Put 1 kg of cocoon layer into 20 liters of 0.5% neutral soap solution, boil for 2 hours, remove all the sericin around the silk fibroin, and get pure silk silk fibroin after fully washing with hot water.

[0023] The dried pure silk fibroin was dissolved into a silk fibroin mixed solution with 1.5 liters of a ternary solution of lithium bromide, ethanol and water in a weight ratio of 44:50:6 and stirred at 75°C for 4 hours. Filtration and purification, ultrasonic defoaming for 1.5 hours to make spinning stock solution.

[0024] as attached figure 1 As shown, under the action of 0.3MPa nitrogen, use two spinning holes with a diameter of 0.5mm, and at a temperature of 30°C, spray the silk fibroin spinning stock solution at a speed of 3 grams per minute, and enter the concentration of methanol at 20°C. In the 60% coagulation solution, it is coagulated into primary silk fibroin fibers.

[0025] After washing with water, immerse in the first drawing bath, the drawing solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com