Process for producing aspartame derivative, crystals thereof, novel production intermediates therefor and process for producing intermediate

A manufacturing method and technology of aspartame, applied in the field of high-intensity sweeteners, can solve the problems such as not being very favorable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

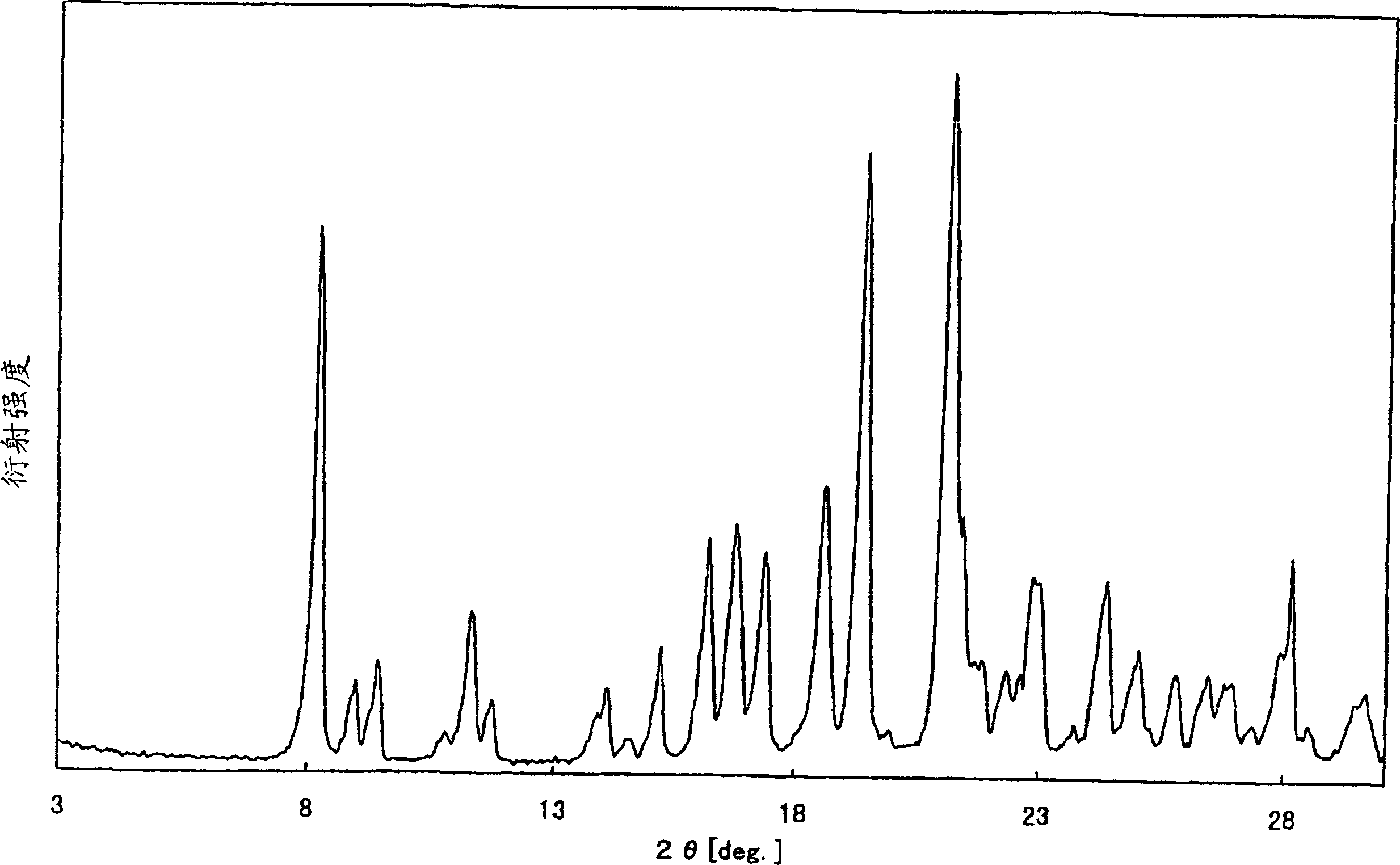

Image

Examples

Embodiment 1

[0115] Synthesis of 3-(3-chloro-4-methoxyphenyl)-3-methylbutanoic acid

[0116] 95% sulfuric acid (72.4 g) and 3-methyl crotonic acid (35.1 g) were added to 2-chloroanisole (100.0 g), heated and stirred at 70° C. for 67 hours, and then water (200 ml) was added to terminate the reaction. After extraction with 400 ml of dichloromethane, 200 ml of 1 N aqueous sodium hydroxide solution was added to the separated organic layer for further extraction. The separated aqueous layer was acidified by adding hydrochloric acid, extracted with dichloromethane, and the solvent was distilled off. The obtained residue was recrystallized from ethyl acetate and hexane to obtain 10.9 g of 3-(3-chloro-4-methoxyphenyl)-3-methylbutanoic acid (yield 12.7%, p-3-methoxyphenyl crotonic acid). 1 HNMR (CDCl 3 )δ: 1.43(s, 6H), 2.61(s, 2H), 3.87(s, 3H), 6.86(d, J=8.6Hz, 1H), 7.10-7.23(m, 1H), 7.35(d, J = 2.4Hz, 1H). ESI-MS calculated value C 12 h 15 35 ClO 3 =242.3, analytical value 241.3 (MH - )....

Embodiment 2

[0118] Synthesis of 3-(3-bromo-4-methoxyphenyl)-3-methylbutanoic acid

[0119] 95% sulfuric acid (27.6 g) and 3-methyl crotonic acid (5.35 g) were added to 2-bromoanisole (50 g), heated and stirred at 70° C. for 27 hours, and then water (100 ml) was added to terminate the reaction. After extraction with 100 ml of dichloromethane, 100 ml of 1 N aqueous sodium hydroxide solution was added to the separated organic layer for further extraction. The separated aqueous layer was acidified by adding hydrochloric acid, extracted with dichloromethane, and the solvent was distilled off. The resulting residue was recrystallized from ethyl acetate and hexane to obtain 3.1 g of 3-(3-bromo-4-methoxyphenyl)-3-methylbutanoic acid (yield 20.3%, p-3-methoxyphenyl crotonic acid).

Embodiment 3

[0121] Synthesis of 3-(3-bromo-4-methoxyphenyl)-3-methylbutanoic acid

[0122] 2-Bromoanisole (102.4 g) and 3-methyl crotonic acid (16.1 g) were stirred and mixed, aluminum chloride (23.5 g) was added to the resulting solution, and stirred at 70° C. for 5 hours, and the The solution was cooled to room temperature, and then 300 ml of 6N hydrochloric acid was added to terminate the reaction. After extraction with 300 ml of toluene, the separated organic layer was further extracted with 500 ml of a 1 N aqueous sodium hydroxide solution. Next, 6 N hydrochloric acid was added to the separated water layer to acidify it, and after extraction with 600 ml of toluene, the organic layer was concentrated under reduced pressure to obtain crude crystals. The resulting crude crystals were recrystallized from ethyl acetate and hexane to obtain 20.7 g of 3-(3-bromo-4-methoxyphenyl)-3-methylbutanoic acid (45% yield, 3- methyl crotonic acid).

[0123] 1 HNMR (CDCl 3 )δ: 1.43(s, 6H), 2.61(s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com