Desulfurization method and novel sorbents for same

An adsorbent and sulfur removal technology, which is applied in the direction of solid adsorbent liquid separation, separation method, adsorption purification/separation, etc., can solve problems such as loss of octane number, achieve sulfur content reduction, and avoid significant decline in octane number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0105] A slurry prepared by mixing 6.5% by weight titanium dioxide, 13.5% by weight zinc oxide and 80% by weight water was spray dried using a Niro spray dryer. The resulting product having an average particle size of 90 µm was calcined at 899°C for 3 hours.

[0106] The zinc titanate product after 100g gained roasting is dissolved in 59.4gNi(NO 3 ) 2 ·6H 2 O impregnation. The nickel-impregnated zinc titanate was then dried at 148.89°C (300°F) for 2 hours and fired at 635°C (1175°F) for 1 hour.

[0107] The resulting calcined nickel oxide-zinc titanate adsorbent was heated in a reactor at 371.11°C (700°F) at 1.03×10 5 Pa (absolute pressure) (15psia) total pressure and 1.03×10 5 Reduction at a hydrogen partial pressure of Pa (15 psi) for 2.5 hrs produced a reduced nickel-zinc titanate solid sorbent in which the nickel component of the sorbent composition was substantially reduced.

Embodiment II

[0110] The desulfurization ability of the granular nickel-zinc titanate adsorbent prepared in Example I was tested as follows.

[0111] A 2.54 cm (1 in) quartz tube reactor was charged with the unreduced sorbent of Example I in the amounts indicated below. The solid nickel-zinc titanate sorbent was placed on a frit in the middle of the reactor and reduced with hydrogen as described in Example I. A gaseous cracked gasoline containing about 340 ppm sulfur (parts by weight of sulfur compounds based on the weight of the gaseous cracked gasoline) and about 95 ppm sulfur based on the weight of the gaseous cracked gasoline was pumped upward through the reactor. % by weight thiophenes (eg, alkylbenzothiophenes, alkylthiophenes, benzothiophenes, and thiophenes). The flow rate is 13.4ml / hr. Produces sulfurized solid sorbent and desulfurized gaseous cracked gasoline.

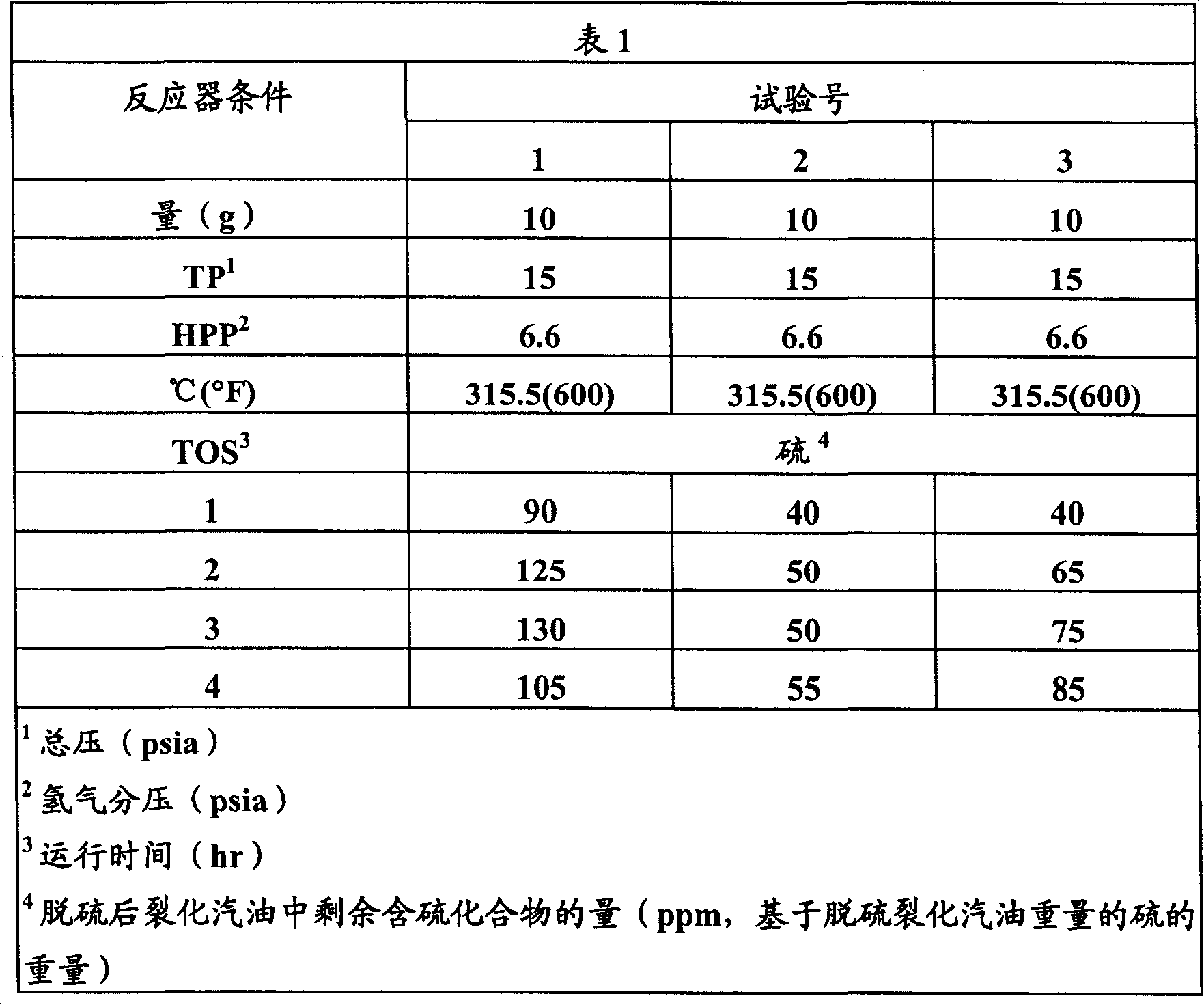

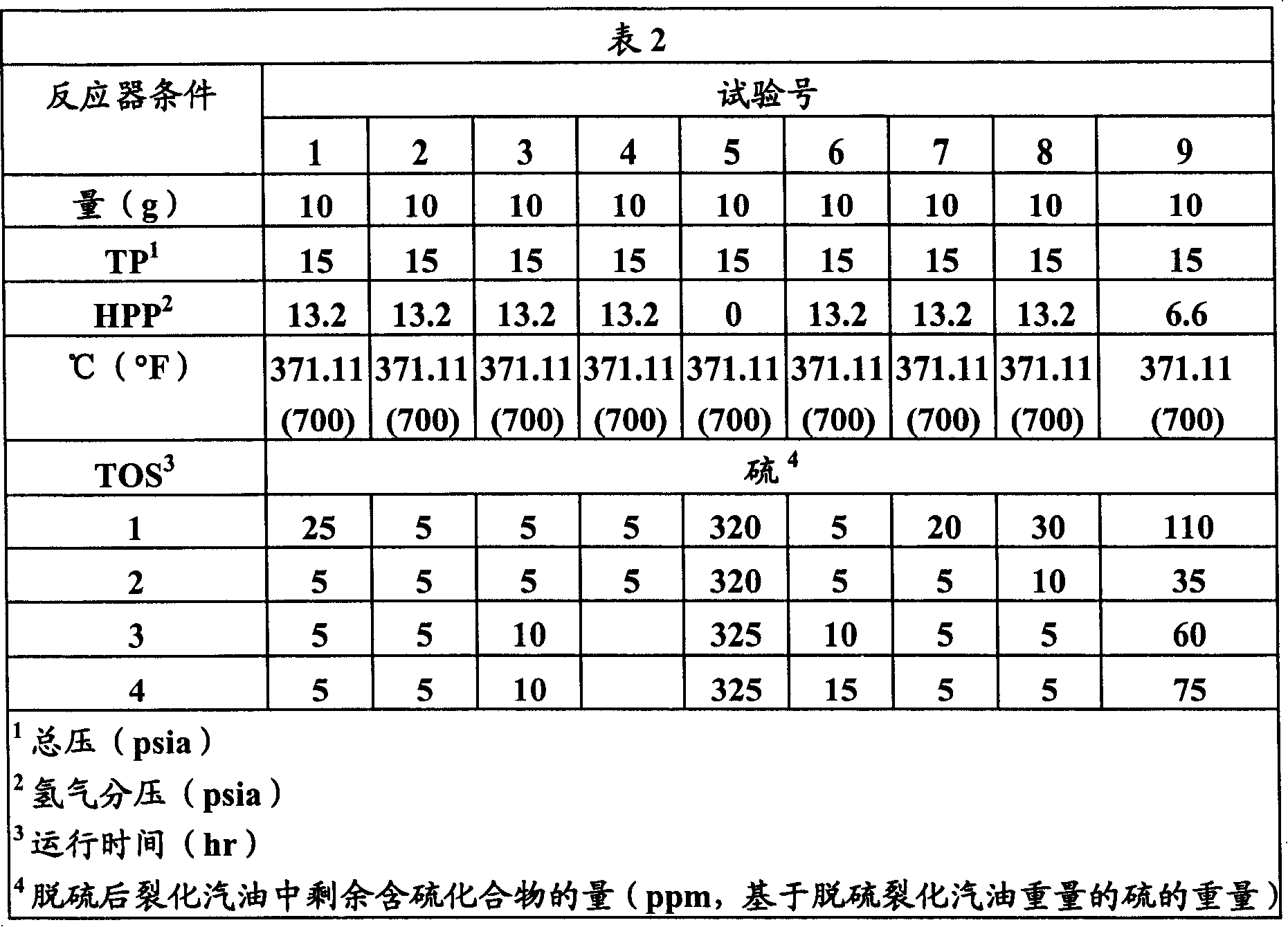

[0112] and get the following result:

[0113] Under the conditions shown in Table 1, the sulfur in gasoline decrease...

Embodiment III

[0119] A slurry prepared by mixing 6.5% by weight titanium dioxide, 13.5% by weight zinc oxide and 80% by weight water was spray dried using a Niro spray dryer. The resulting product having an average particle size of 90 µm was calcined at 899°C for 3 hours.

[0120] The zinc titanate product after 100g gained roasting is dissolved in 59.4gNi(NO 3 ) 2 ·6H 2 O impregnation. The nickel-impregnated zinc titanate was then dried at 148.89°C (300°F) for 2 hours and fired at 635°C (1175°F) for 1 hour.

[0121] 50 g of the resulting nickel-impregnated zinc titanate sorbent was impregnated a second time with 29.7 g of nickel nitrate hexahydrate dissolved in 4 g of deionized water heated to 82.2°C (180°F). After the secondary impregnation, the impregnated sorbent was dried at 148.89°C (300°F) for 1 hour and calcined at 635°C (1175°F) for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com