A kind of hybrid organic framework material loaded with rare earth and its preparation method and application

A metal-organic framework and hybridization technology, which is applied in chemical instruments and methods, refined hydrocarbon oil, and other chemical processes, can solve the problems of limited service life of materials, unassisted desulfurization application technology, and high development costs, and achieve offset space position Resistant effect, enhanced desulfurization effect, strong thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

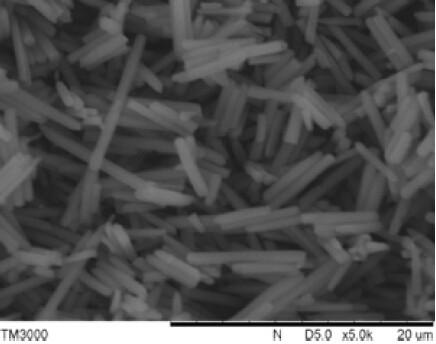

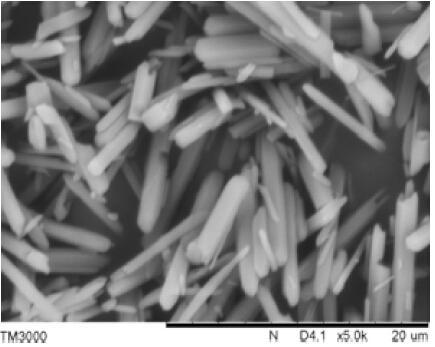

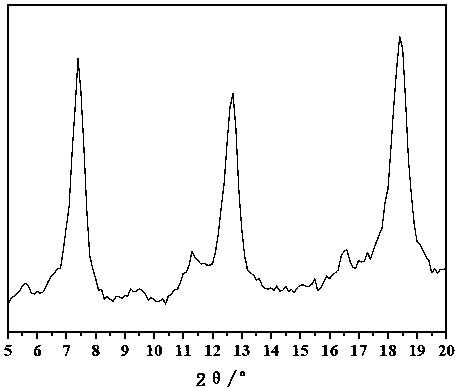

Image

Examples

Embodiment 1

[0045] (1) Preparation of hybrid metal-organic framework materials a

[0046] Weigh 5gCu(NO 3 ) 2 ·3H 2 O. Add 3g of 1,4,5,8-naphthalene tetracarboxylic acid into 2000g of acetone aqueous solution, the volume ratio of acetone and water is 1:2, the pH after mixing is 0.73, and put it in an ultrasonic oscillator after airtight, adjust the ultrasonic The frequency is 100KHz, the ultrasonic power is 450W, and it is ultrasonically oscillated at room temperature until a sky blue precipitate appears. Add dropwise an aqueous solution containing 0.27 g of soluble starch in mass concentration, wherein the concentration of soluble starch is 25 wt %, keep the ultrasonic conditions unchanged, and continue ultrasonication for 35 min. The obtained mixed solution is suction-filtered, and the filter cake is put into an aqueous acetone solution containing ammonium chloride. The mass ratio of the filter cake to ammonium chloride is 1:1, and the ratio of ammonium chloride to acetone is 1g:120m...

Embodiment 2

[0050] The method and raw material are basically the same as in Example 1, except that the copper source is replaced by CuSO 4 ·5H 2 O, other reaction conditions and material composition remain unchanged, and the CeO 2 The hybrid metal-organic framework B.

Embodiment 3

[0052] The method and raw materials of Example 1 are basically the same, the difference is that the volume ratio of acetone and water in the solvent is increased to 1:10, and other reaction conditions and material composition are unchanged, and the CeO is loaded 2 The hybrid metal-organic framework C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com