2D photon Si-base crystal waveguide don insulator with dual insulating burried layers and its preparing process

A two-dimensional photonic crystal and photonic crystal waveguide technology, applied in the field of optoelectronics, can solve the problems of narrow photonic band gap, small dielectric constant, poor repeatability, etc., and achieve the effect of good single crystal quality, low energy loss and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

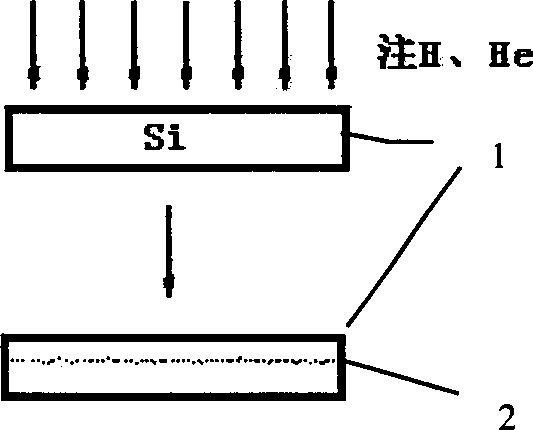

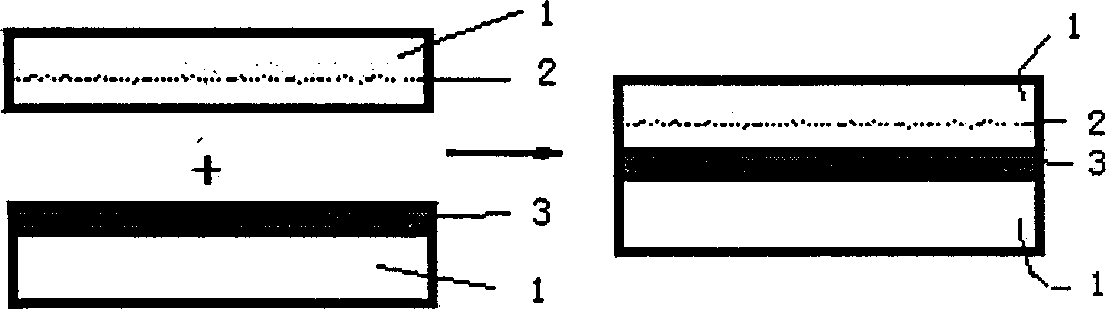

[0036] The high-quality SOI prepared by the improved Smart-Cut method is used as the substrate of the two-dimensional photonic crystal. First implant the energy of 30KeV into the single crystal silicon wafer 1, and the dose is 1×10 16 / cm 2 H + , the re-implantation energy is 33KeV, and the dose is 1×10 16 / cm 2 He + ; During implantation, the ion beam deviates from the normal line of the sample by 7°, while keeping the temperature of the target below 200°C during the implantation process; the support sheet adopts a double buried layer (SiO 2 / Si 3 N 4 ), SiO 2 Prepared by ultra-high vacuum electron beam evaporation (UHV-EBE), the substrate temperature is 200 ° C, Si 3 N 4 Low-pressure chemical vapor deposition (LPCVD) is used, and the substrate temperature is 1000°C. Then bond, and then heat-treat the bonded sheet at 520°C, the sheet is cracked from the bubble layer 2 and facet formed by H and He injection: annealing at 1100°C strengthens the bond and forms a high-q...

Embodiment 2

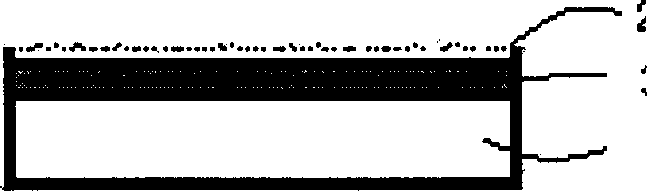

[0039] In order to obtain two-dimensional photonic crystal waveguides with different photonic band gaps, in the air holes of the two-dimensional photonic crystal waveguides formed in method 1, deposit other dielectric materials (SiO 2 ,TiO 2 , Ta 2 o 5 etc.), such as using UHV-EBE method to grow 1μm thick TiO 2 ( Figure 10 )5, the background vacuum of the target chamber reaches 10 -8 ~10 -9 Torr, the substrate temperature is 200°C, and the growth rate is 1 Å / s; the surface is then CMPed to form a two-dimensional photonic crystal waveguide ( Figure 11 ).

Embodiment 3

[0041] The double buried layer used in the support sheet is SiO 2 / AlN, SiO 2 Formation of 0.8μm SiO by thermal oxidation 2 layer, AlN is deposited by low-pressure chemical vapor deposition (LPCVD), the substrate temperature is 900°C, the thickness is 1.2 μm, and the total thickness of the double insulating buried layer is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com