Methane synthesizing method and equipment with slurry bed member

A methanol synthesis, slurry bed technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of reduced catalyst utilization, incomplete reaction, shortened residence time, etc., to achieve yield Improved, easy temperature adjustment, the effect of great flexibility in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

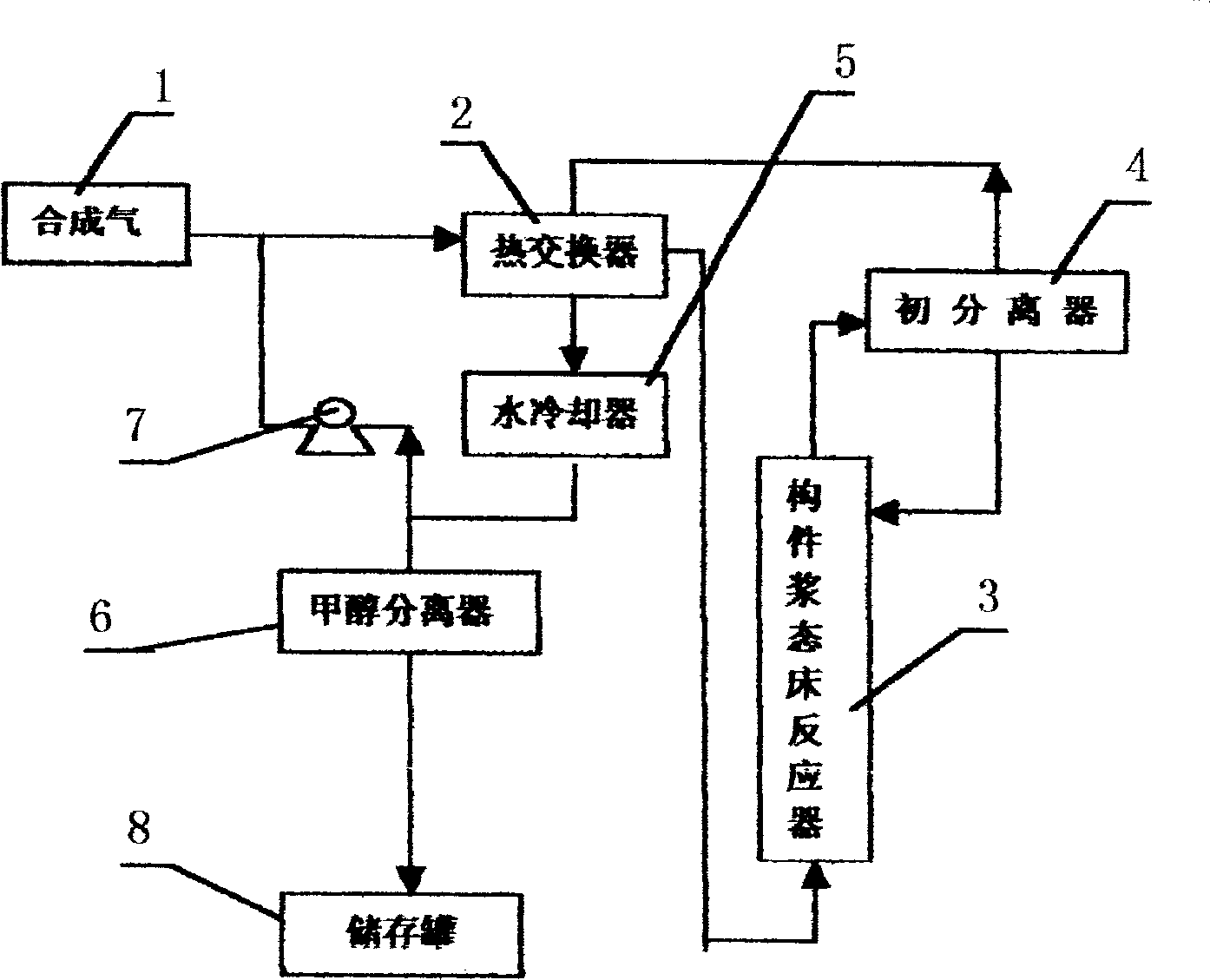

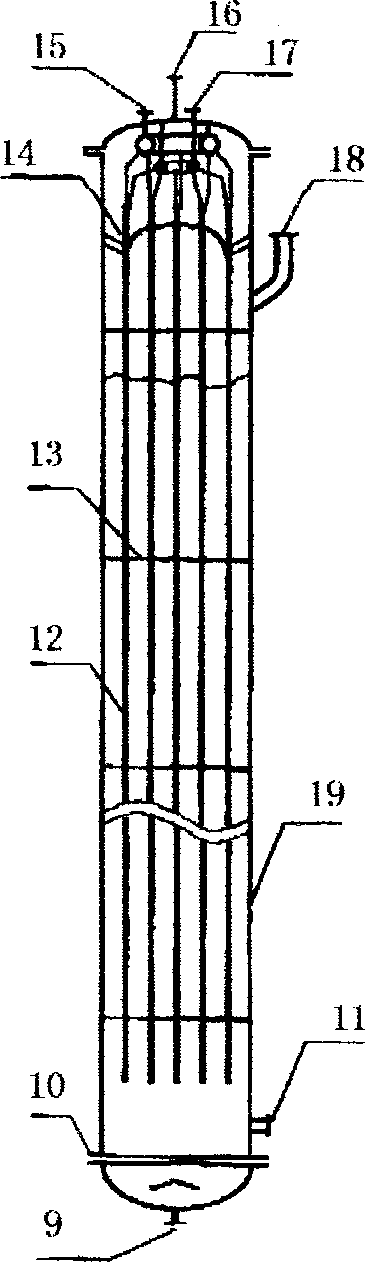

[0024] figure 1 Shown is the reaction process flow chart of methanol slurry bed synthesis. First from the catalyst slurry inlet 18 of the component slurry bed reactor 3 (such as figure 2 shown), add an inert solvent, liquid paraffin, and a methanol synthesis catalyst with a particle size of 150 to 180 meshes, the weight ratio of the catalyst to the inert solvent is 20%, and the methanol synthesis catalyst and the solvent form a slurry system together. Syngas (H 2 , CO, CO 2 )1 After reduction at a certain temperature and pressure, press H 2 / (CO+CO 2 ) is 2:1 synthesis, after heat exchange by the compressor pump 7 and the heat exchanger 2, the synthesis gas inlet 9 at the bottom of the reactor 3 is bubbled into the tank body 19 of the reactor 3 for reaction. Its reaction process is:

[0025] 1). Put H 2 / (CO+CO 2 ) the synthesis gas 1 with a volume ratio of 1:1 to 4:1, passes through the synthesis gas compression pump 7 and the heat exchanger 2, so that the synthesis ...

Embodiment 2

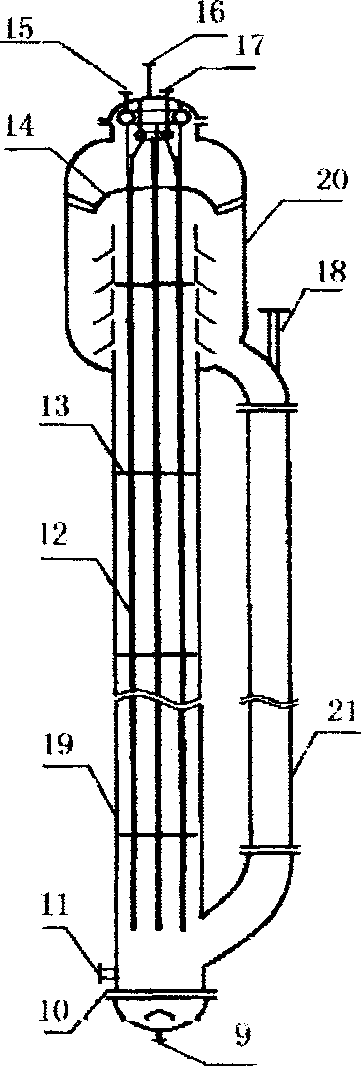

[0032] image 3 Shown is the progress of the methanol synthesis process in the component circulating slurry bed reactor, which is basically the same as in Example 1, the difference is that the weight ratio of the catalyst to the inert solvent is 30%, and the synthesis gas space velocity is 3000h -1 . The main products produced by the reaction are methanol and a small amount of methane, the single-pass conversion rate of CO can reach 55%, and the selectivity of methanol is greater than 98%. In addition, a gas-liquid separation chamber 20 is installed on the top of the reactor 3, and is communicated with the lower part of the tank body 19 by a downcomer 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com