Atractylodes polyose with antineoplastic and immunoregualting functions and its preparing process and application

An Atractylodes macrocephala polysaccharide and a production method technology are applied in the directions of antitumor drugs, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as no biological activity reports, etc., achieve simple extraction and separation methods, inhibit tumor growth, and enhance immunity. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Wash and dry 1 kg of crude drug Atractylodes macrocephala, crush it, soak it in 10 liters of deionized water at room temperature for 1 hour, decoct it under normal pressure for 1 hour without constant stirring, and filter. Continue decocting the residue with 5 liters of deionized water for 1 hour, filter, combine the filtrates, and concentrate under reduced pressure at 60°C to 2-4 liters. Then use 95% ethanol for precipitation, the final concentration of ethanol is 80%, and alcohol precipitation for 24 hours. Centrifuge, dissolve the precipitate with 2.5 liters of water, centrifuge, and dialyze with deionized water for 48-72 hours. Concentrate under reduced pressure at 60°C and freeze-dry to obtain 100 grams of Atractylodes macrocephala polysaccharide. Add 2 liters of water to dissolve, centrifuge, add 4 liters of 95% ethanol to the supernatant for 24 hours, and centrifuge. Add 4 liters of 95% ethanol to the supernatant for 24 hours, centrifuge, dissolve the precipita...

Embodiment 2

[0029] Wash and dry 1 kg of the crude drug Atractylodes macrocephala, crush it, soak it in 10 liters of deionized water at room temperature for 2 hours, decoct it under normal pressure for 1 hour without constant stirring, and filter. Continue decocting the residue with 5 liters of deionized water for 1 hour, filter, combine the filtrates, and concentrate under reduced pressure at 60°C to 4 liters. Then use 6 times volume of 95% ethanol for precipitation, the final concentration of ethanol is 82%, and alcohol precipitation for 72 hours. Centrifuge, dissolve the precipitate with 4 liters of water, centrifuge, and dialyze with deionized water for 72 hours. Concentrate under reduced pressure at 55°C and freeze-dry to obtain 120 grams of Atractylodes macrocephala polysaccharide. Add 2 liters of water to dissolve, centrifuge, add 4 liters of 95% ethanol to the supernatant for 24 hours, and centrifuge. Add 4 liters of 95% ethanol to the supernatant for 24 hours, centrifuge, dissol...

Embodiment 3

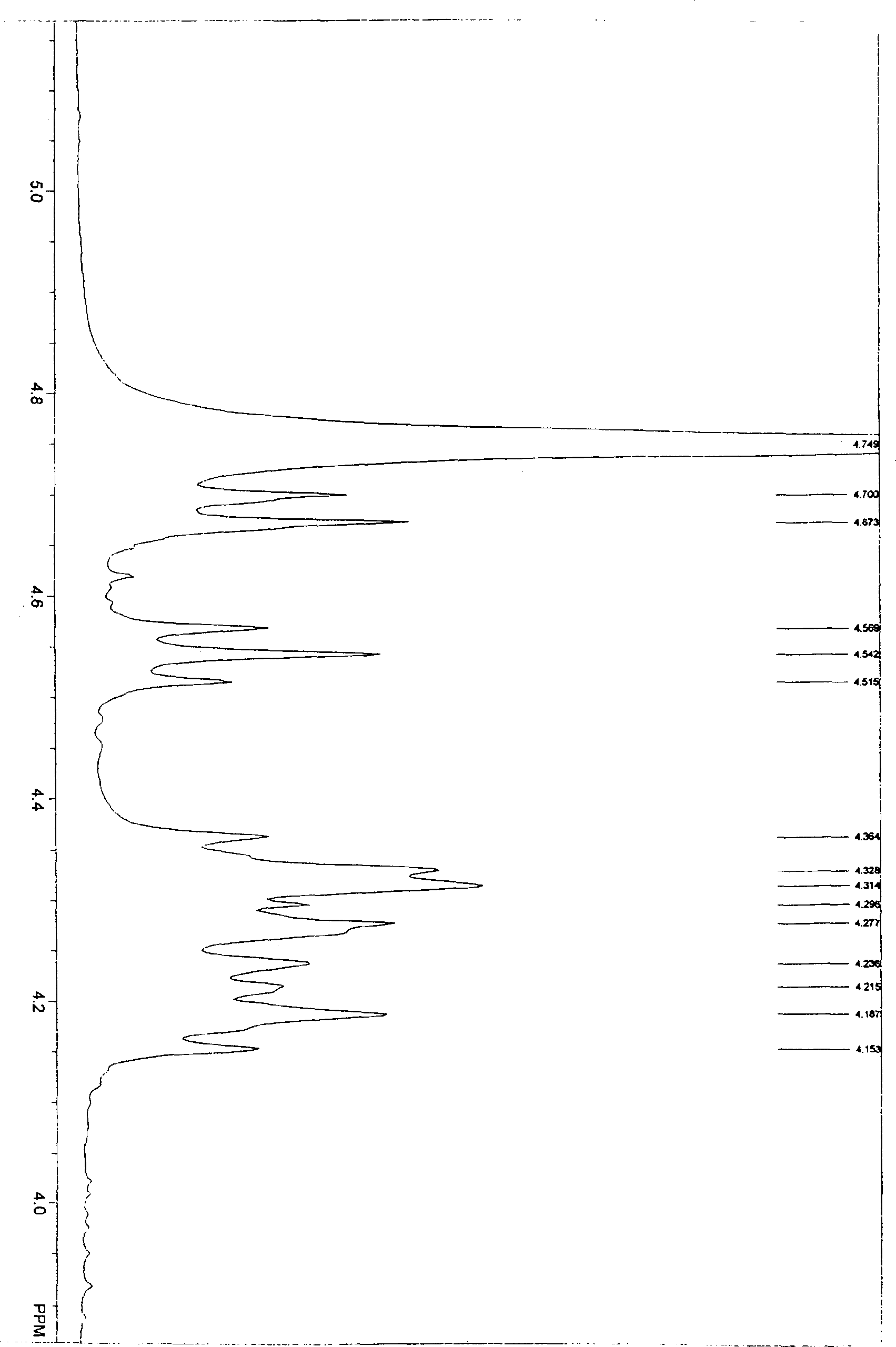

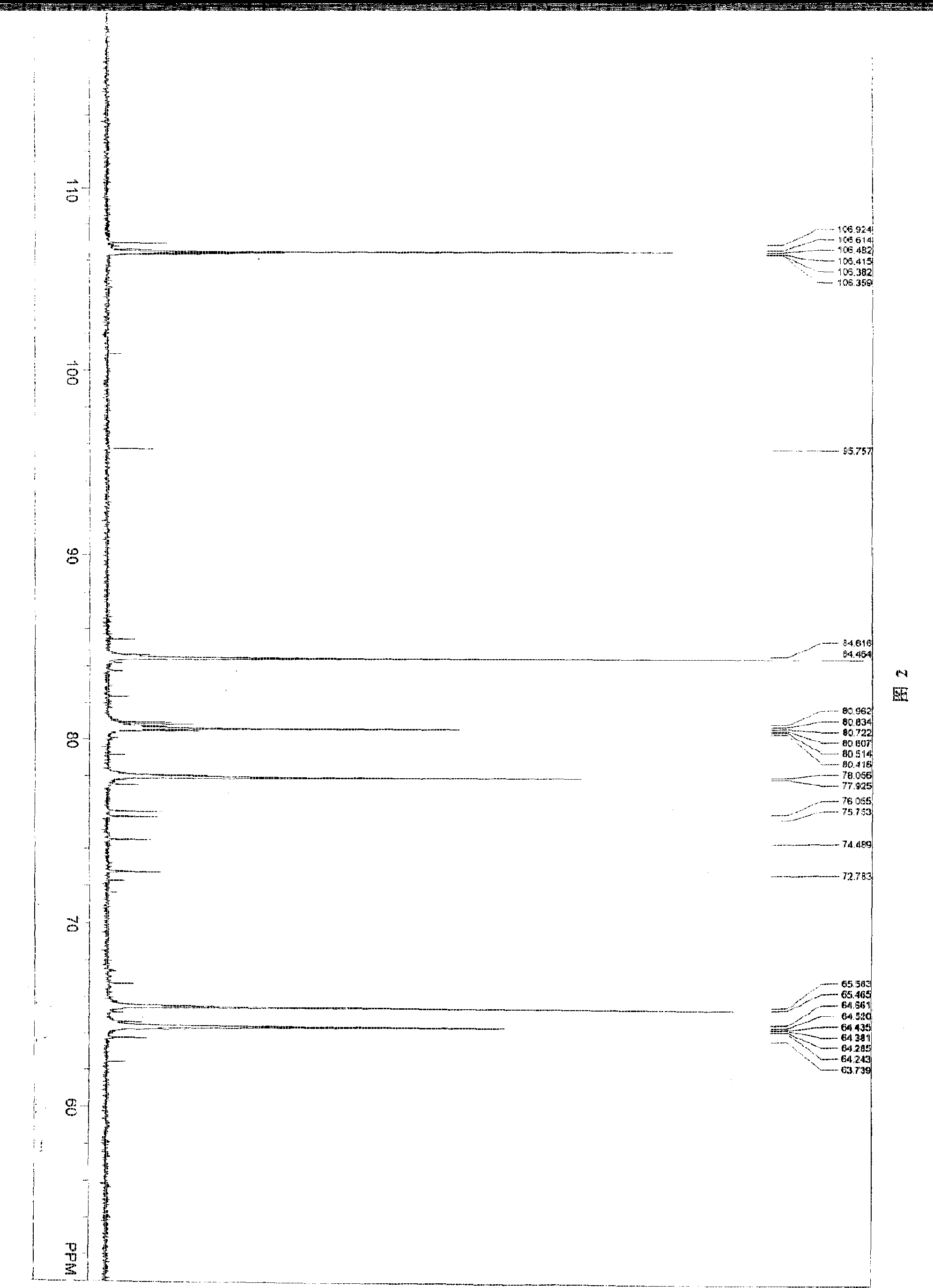

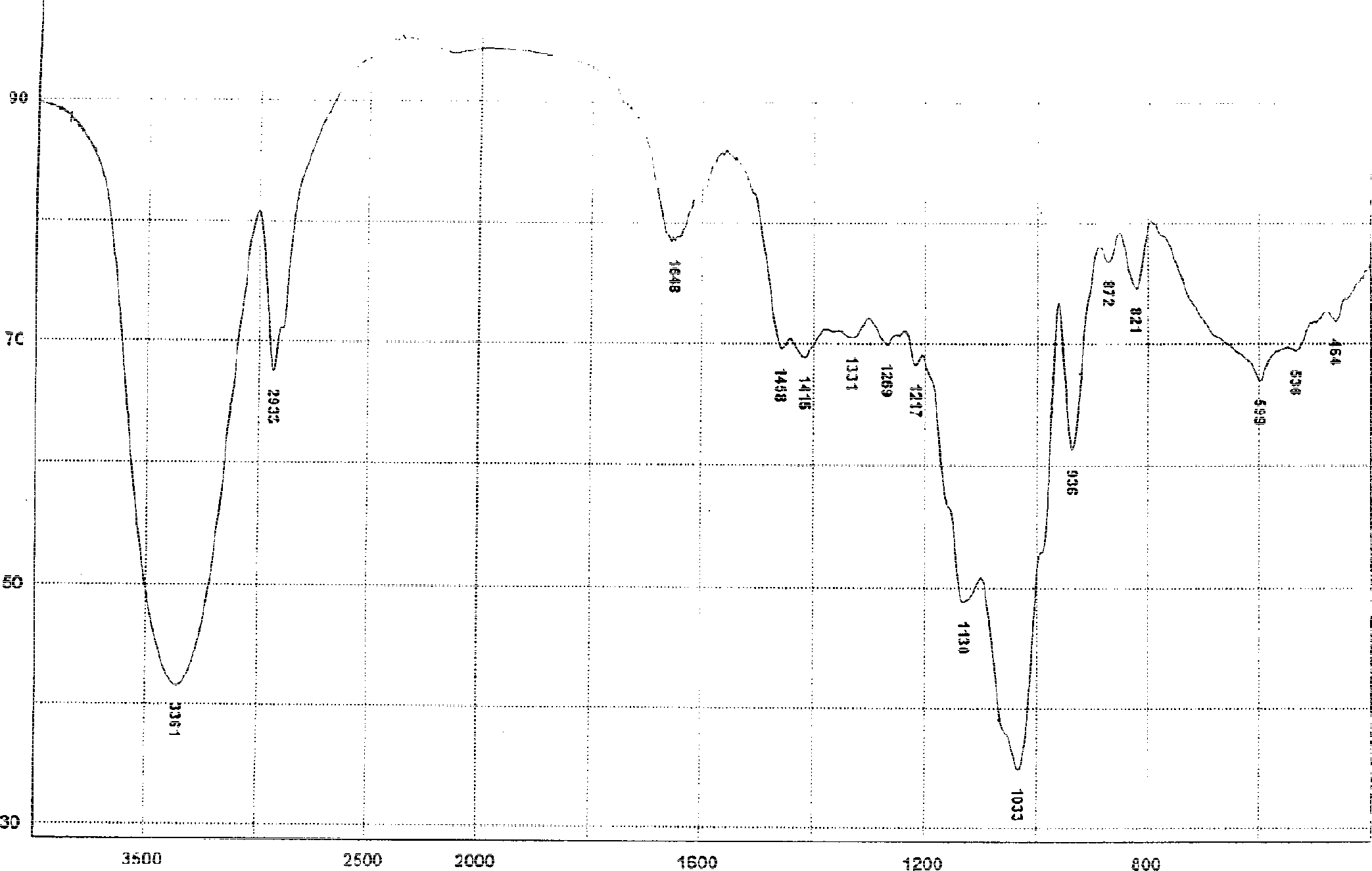

[0031] The total polysaccharides of Atractylodes macrocephala were fractionated and precipitated with different concentrations of ethanol to obtain refined polysaccharides with a molecular weight of about 3800, with a purity of 90-95%. The polysaccharides were then subjected to Sephadex-G-25 column chromatography to obtain pure polysaccharides with a purity of 99%. Specific separation method: Weigh 150mg of refined polysaccharide, dissolve in 3-5ml distillation, and centrifuge (4500r / min, 10min). Put the supernatant on a glass column (1.5cm*100cm), elute with 0.1M NaCl at a flow rate of 0.5ml / min, collect 3-5ml in each tube, and about 10-20 tubes are the absorption peak. Collected, dialyzed with distilled water for 24 hours, and freeze-dried to obtain 110 mg of pure polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com