Method for preparing high-activity titanium dioxide film self-cleaning glass material

A technology of titanium dioxide and glass materials, which is applied in the field of self-cleaning glass materials for the preparation of high-activity titanium dioxide films, which can solve the problems of difficult control of coating quality, low photocatalytic activity, and no self-cleaning, and achieve the effect of easy and effective control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] T, D, H, E and P represent butyl titanate, diethanolamine, water, absolute ethanol and polyethylene glycol (PEG), respectively.

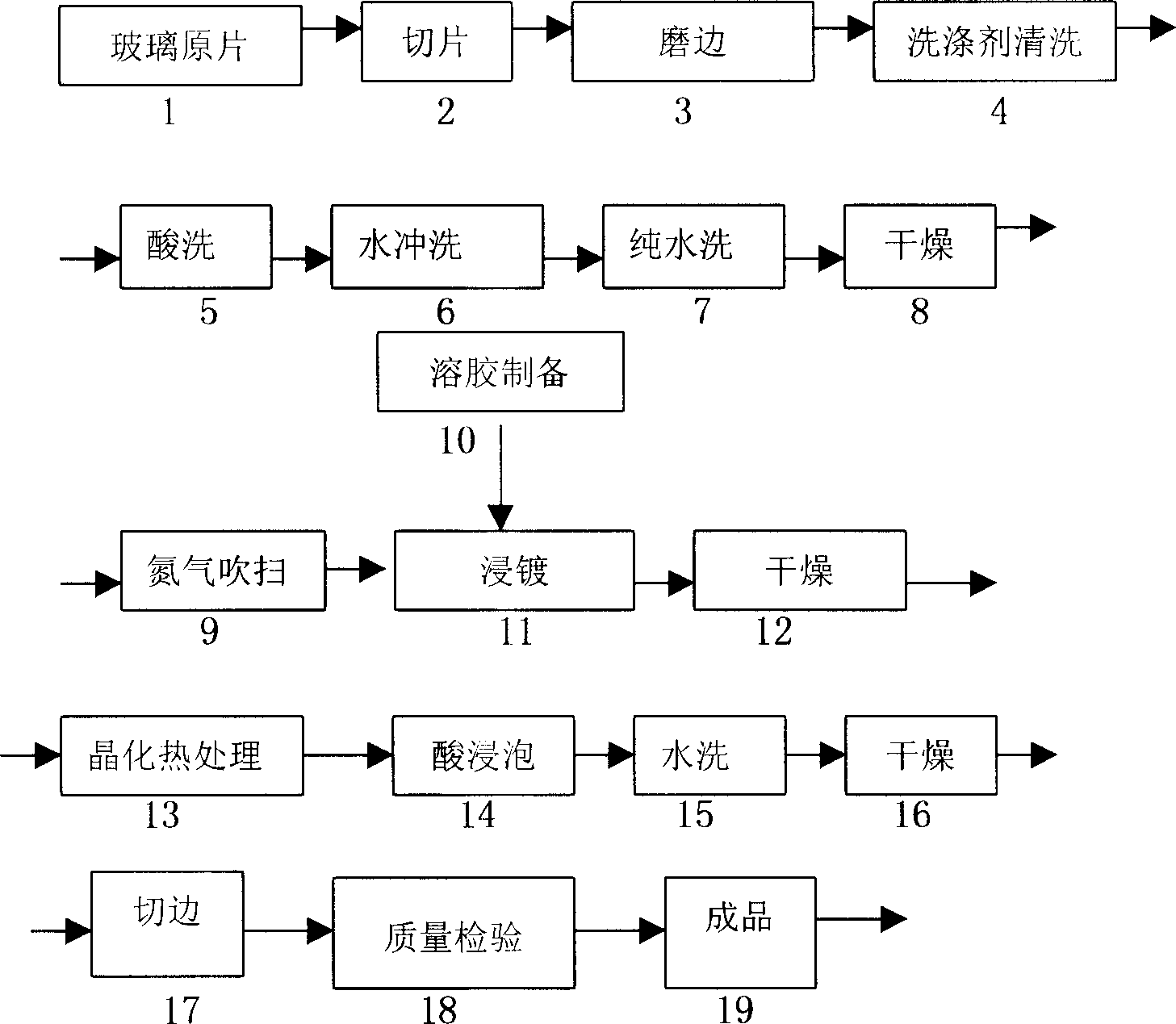

[0034] The method suitable for industrial production is as follows:

[0035] 1. Original glass sheet: Select high-quality original float glass sheet and mount it on a rack for use. The glass is required to be fresh and free of appearance defects such as scratches.

[0036] 2. Slicing: Cut the glass according to the requirements of the production process and the needs of the user. Size error ≯±1.5mm.

[0037] 3. Edge grinding: Use an abrasive belt edger to grind the glass cutting edge. It is required that there are no burrs around the glass.

[0038] 4. Detergent cleaning: Clean the glass surface with detergent on the washing machine to remove organic matter such as oil and hand grease on the glass surface.

[0039] 5. Acid cleaning: Clean the glass surface with a dilute acid solution on the cleaning machine to remove inorganic substances...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com