Ultraviolet photosensitive device

A technology for photosensitive devices and ultraviolet rays, which is applied to the measurement of ultraviolet rays, electric solid-state devices, semiconductor devices, etc., and can solve problems such as large-scale, band-pass filter degradation, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

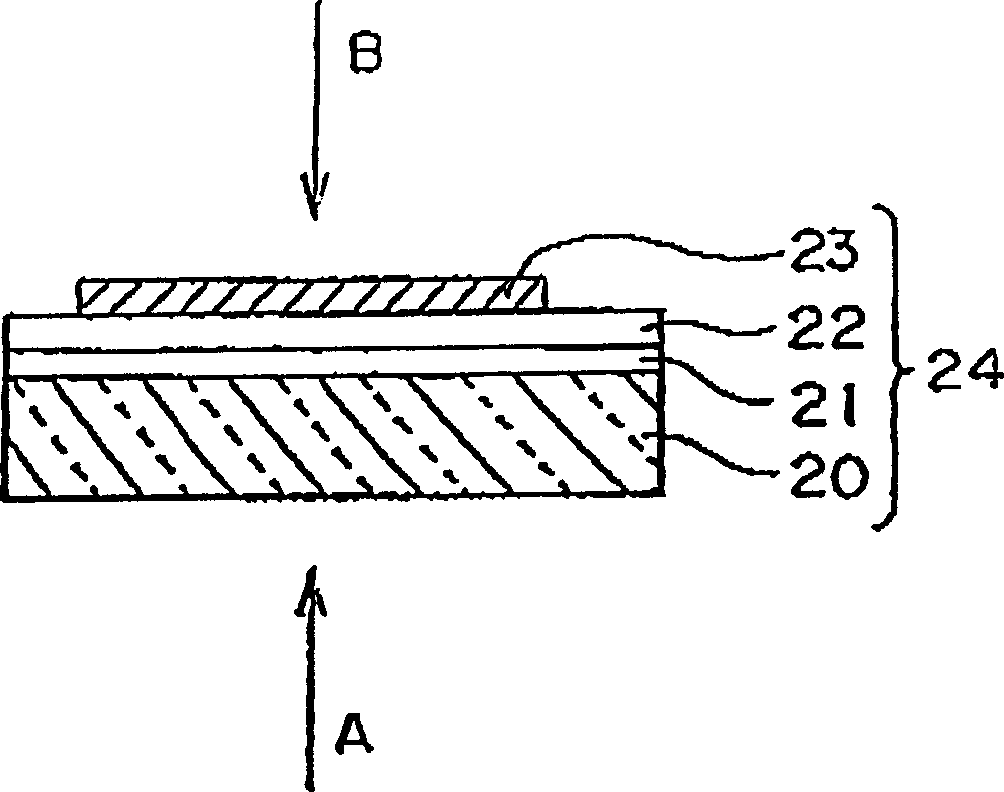

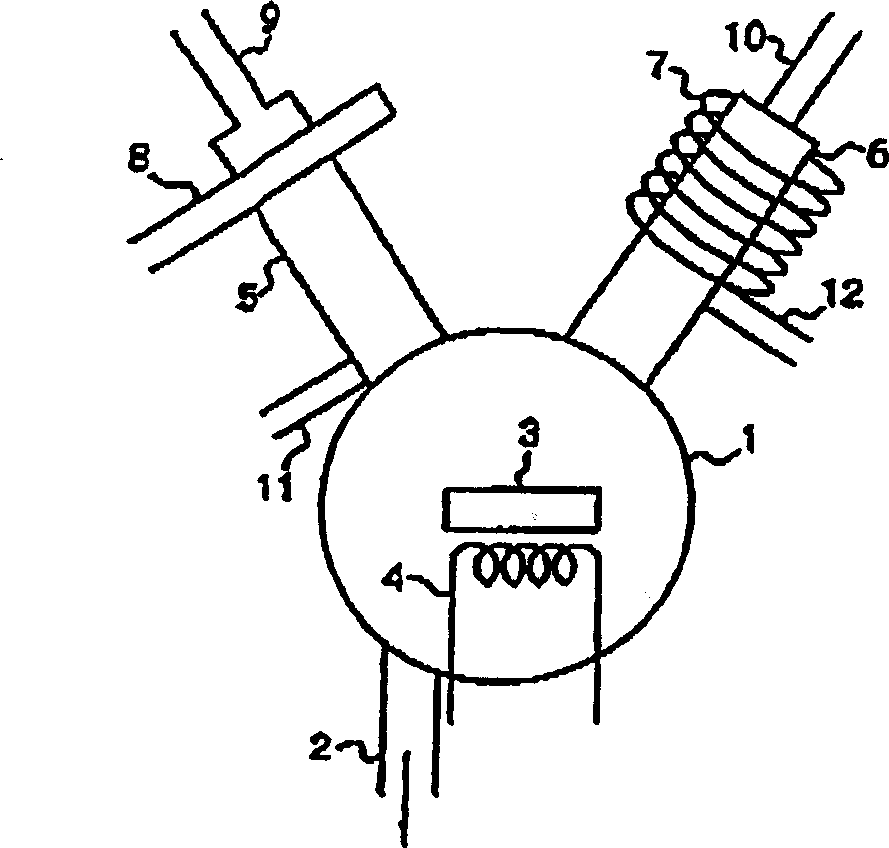

[0118] A cleaned quartz substrate (thickness: 0.2 mm, length: 10 mm, width: 10 mm) was placed on the substrate holder 3 . Then, use a rotary pump and a mechanical booster turbo pump connected to the exhaust port 2 to vacuum exhaust the reaction chamber 1 so that its back pressure is lower than 10 -3 Pa, the above-mentioned quartz substrate is heated to about 500 degrees Celsius by the heater 4 .

[0119] Afterwards, the nitrogen gas of 1000 sccm (standard cubic centimeter per miniutue) is introduced into the quartz tube 5 with a diameter of 25 mm through the gas introduction pipe 9, and the output power of the microwave at 45 GHz is adjusted to 250 W by the regulator, and then passed through the microwave conduit 8 to discharge. The reflected wave at this time was 0W. Furthermore, 1 sccm means that at 1013.25 hPa (1 atmospheric pressure) and 0 degrees Celsius, the flow rate of gas is equivalent to 1 cubic centimeter per minute.

[0120]Furthermore, 500 sccm of hydrogen gas ...

example 2

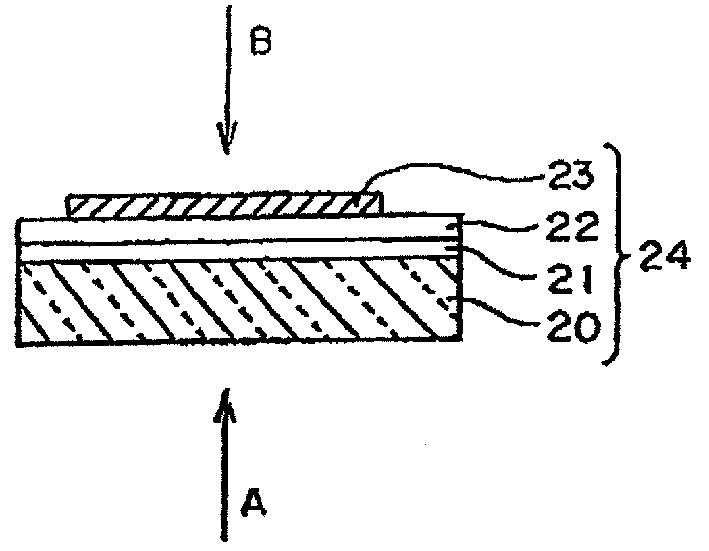

[0138] Except that when forming the first electrode layer, only trimethylaluminum, which is the raw material of group IIIA elements, is introduced into the gas introduction tube 11 under the same conditions as in Example 1, all the others are carried out under the same conditions as in Example 1. Formation of an electrode layer.

[0139] Thus, on the surface of the quartz substrate, a silicon-doped AlN:H film with a film thickness of 100 nm was formed as a first electrode layer. In addition, the hydrogen content in the film measured by the IR method (infrared spectroscopic analysis method) was 5 atomic %.

[0140] Then, after the film-forming chamber 1 returns to atmospheric pressure, the quartz substrate on which the first electrode layer has been formed is taken out from the film-forming chamber 1, and the end of the first electrode layer is covered with a metal mask, and then the aforementioned substrate is formed with the first electrode layer. An electrode layer is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com