High performance alumina bioceramic sintered under normal pressure and low temp

A bio-ceramic, low-temperature sintering technology, applied in medical science, prosthesis, etc., can solve the problems of reducing alumina, affecting the strength of materials, adverse effects on the biological properties of materials, etc., to achieve the effect of promoting sintering and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

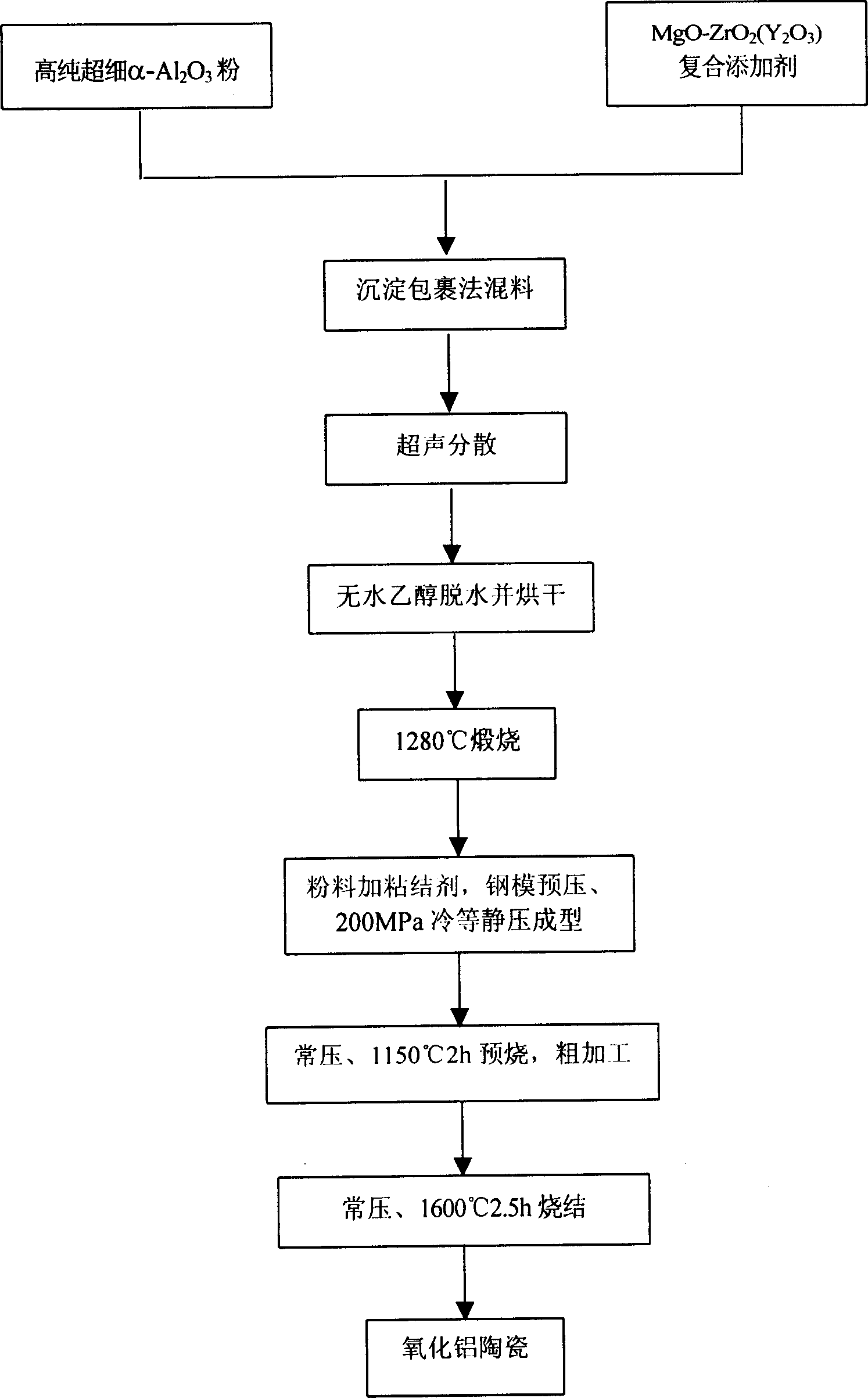

[0030] First, use α-Al with a purity of 99.9% and an average particle size of 0.35 μm 2 o 3 The powder is prepared according to the material-water ratio of 1:3 and the α-Al 2 o 3 Suspension; Mg(NO 3 ) 2 ·6H 2 O, ZrOCl 2 ·8H 2 O+Y 2 o 3 +HCl(3mol%Y 2 o 3 Stable ZrO 2 ) and other aqueous solutions, and mixed so that the concentration of the mixed solution is 1mol / L; the precipitation coating method is used to mix the materials, and while fully stirring, the α-Al 2 o 3 The suspension is introduced into the mixed solution, MgO-ZrO 2 (Y 2 o 3 ) The total weight percentage of the composite additive remains 4%, and excessive 1mol / L ammonia water is added dropwise in the mixture, and its precipitation is complete under the condition that the pH value is 9; Using ultrasonic cavitation to disperse the agglomerates, which is conducive to the uniform dispersion of small particles of additives into α-Al 2 o 3 Particles go in the primary particle.

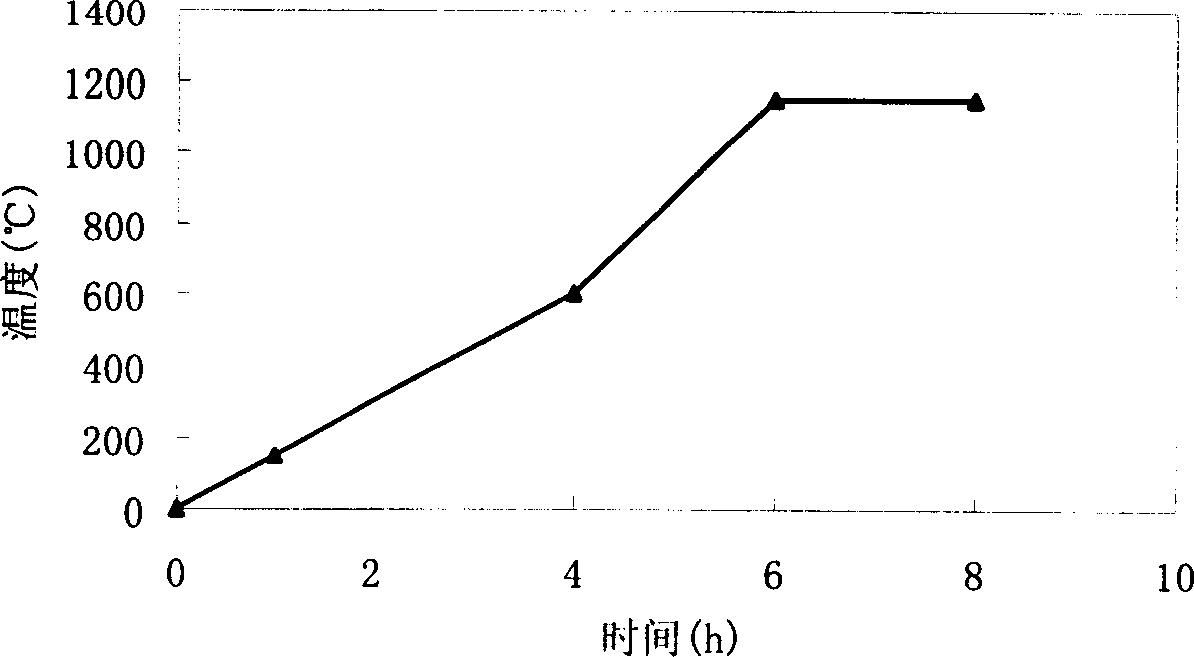

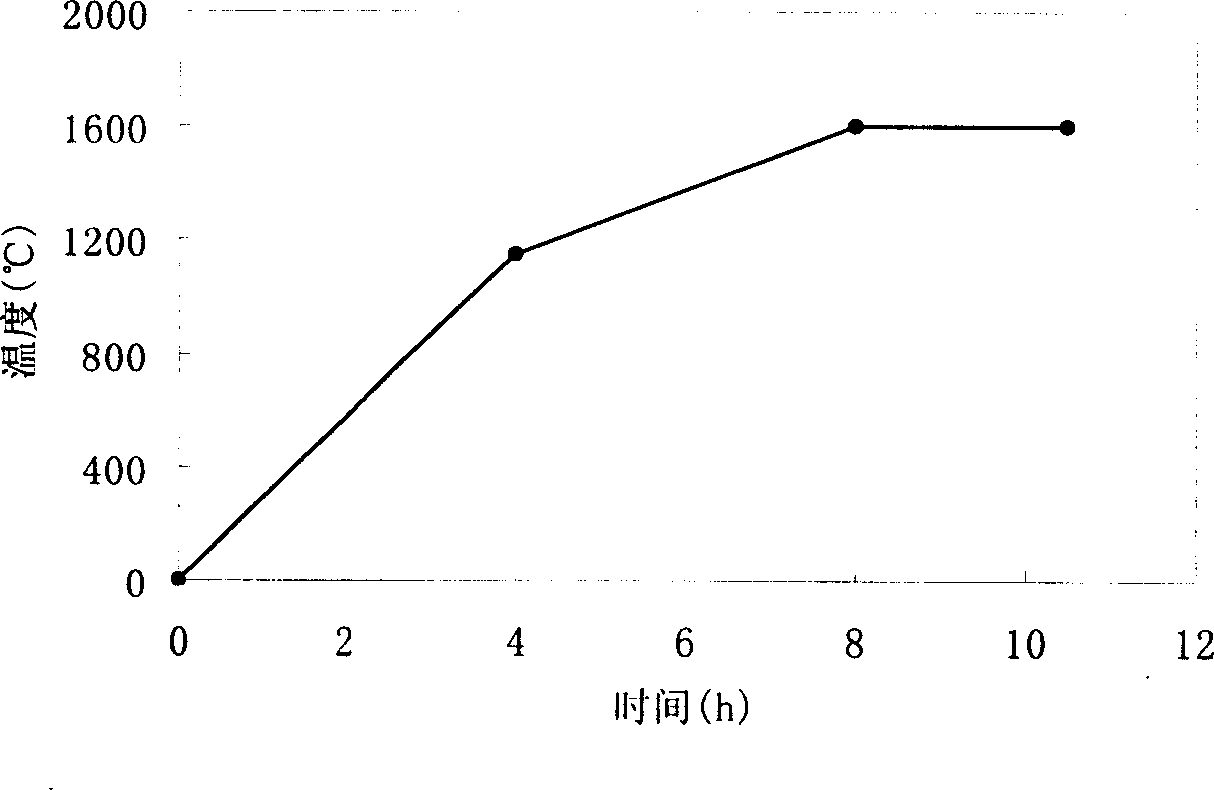

[0031] Then, dehydrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com