Blue light emitting device of III group nitrogen semi-conductor

A technology of nitride semiconductors and light-emitting devices, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large lattice mismatch, high defect density of epitaxial layers, and low mobility, so as to reduce scattering and improve electrical properties , the effect of improving the migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

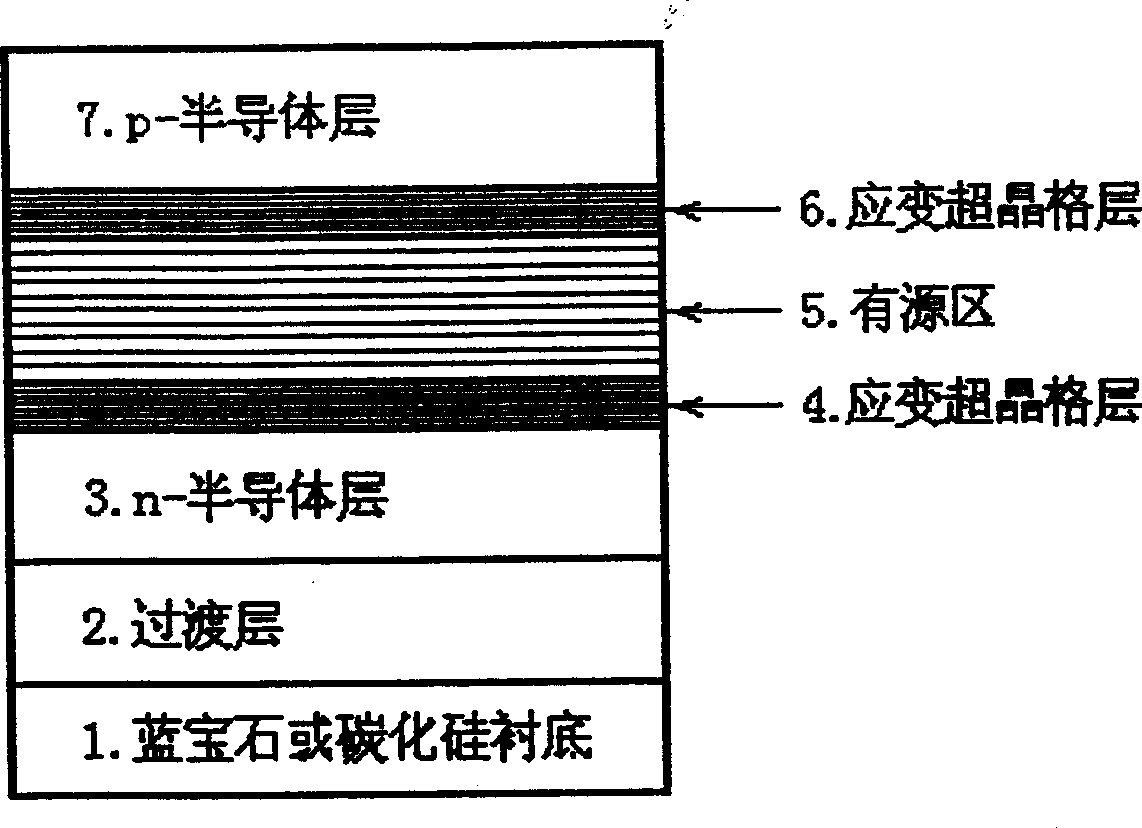

[0021] Such as figure 1 As shown, in α-Al 2 o 3 Undoped GaN2, n-type GaN3, n-type strained layer superlattice 4, InGaN / GaN multiple quantum wells 5, p-type strained layer superlattice 6 and p-type GaN7 are sequentially grown on the substrate 1.

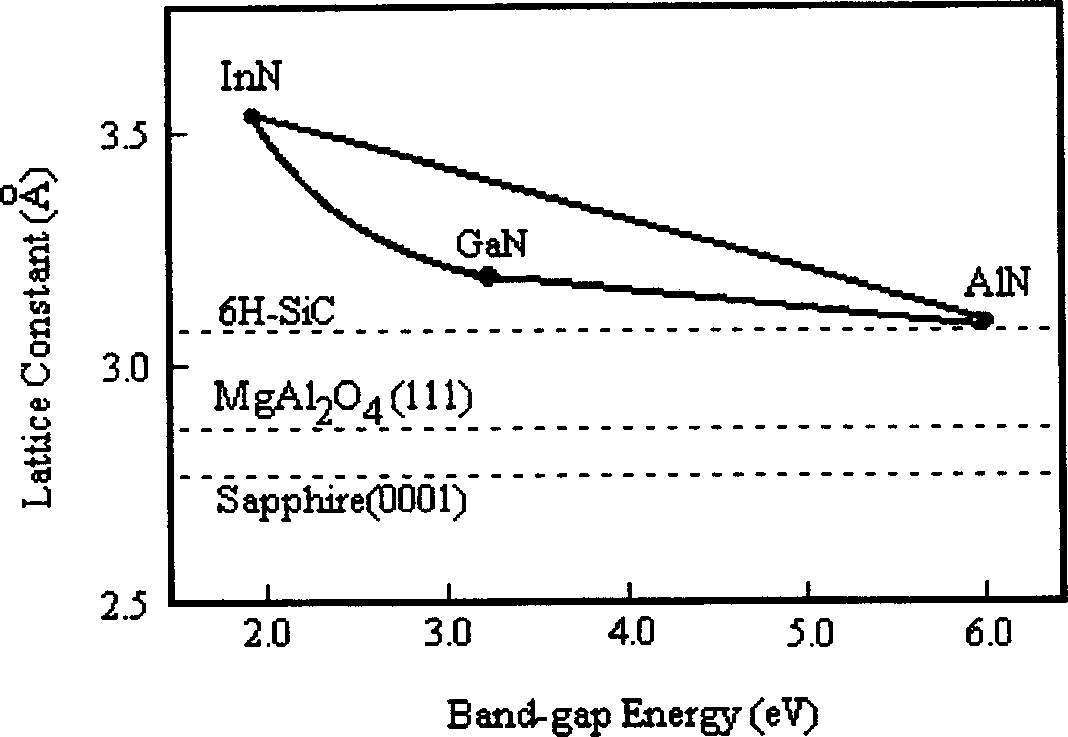

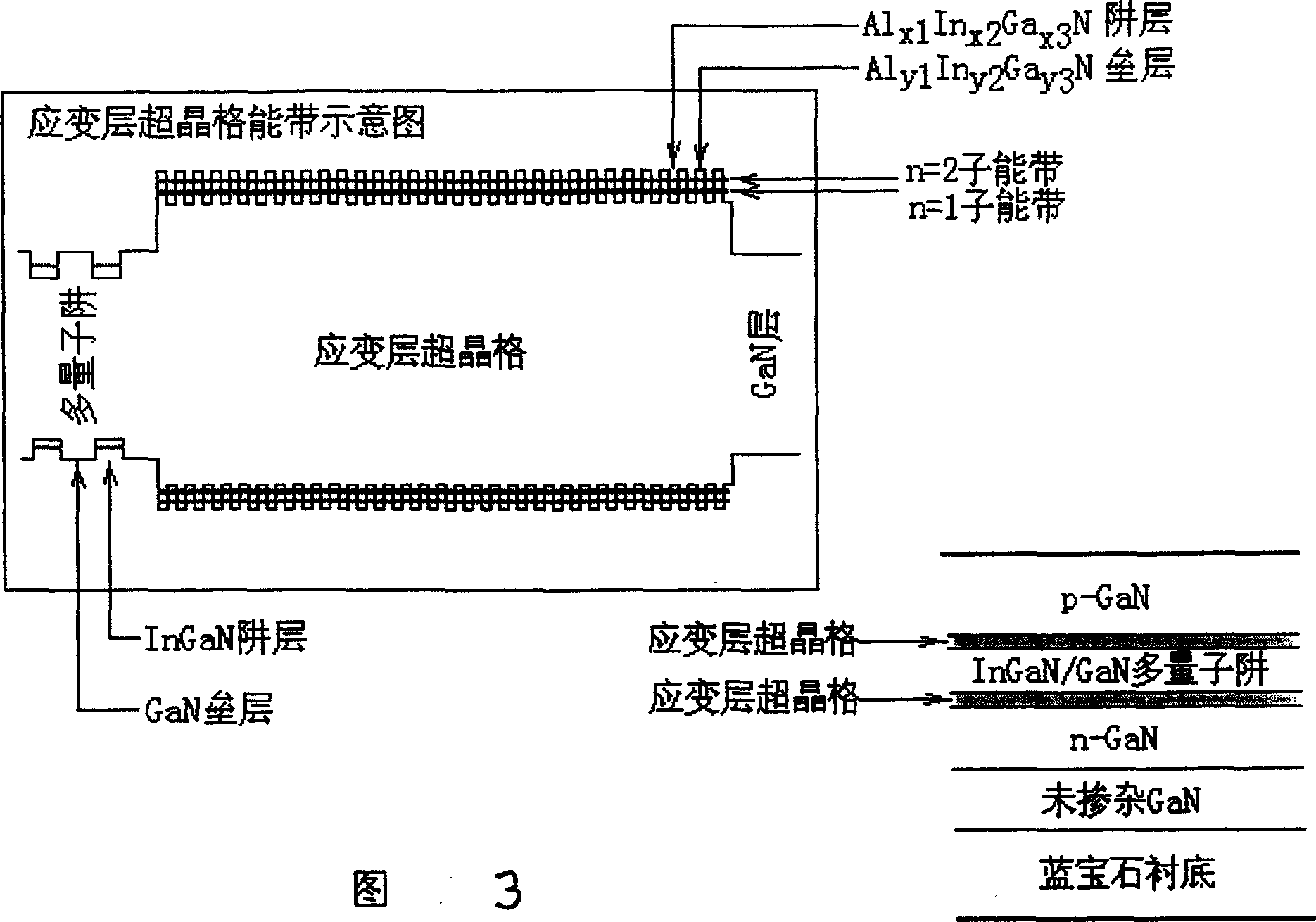

[0022] Such as figure 2 As shown, it represents III-V semiconductor materials GaN, InN, AlN and substrate materials 6H-SiC, MgAl 2 o 4 (111), α-Al 2 o 3 The lattice constant and energy band gap. It can be seen that the lattice constant of InN is larger than GaN, and the band gap is smaller than GaN; while the lattice constant of AlN is smaller than and close to GaN, and the band gap is much larger than GaN. Therefore, the M shown in Figure 3 can be selected * (Al x1 In x2 Ga x3 N-Al y1 In y2 Ga y3 N) Strained layer superlattice as cladding. At this time, y2 takes zero or a smaller value, Al y1 In y2 Ga y3 The lattice constant of the N barrier layer is similar to that of the usual AlGaN cladding layer, and slightly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com