Diamine modified poly-latic acid, method for preparing same and use thereof

A polylactic acid and amine modification technology, which is applied in the field of diamine-modified polylactic acid and its preparation, can solve the problems of accelerating body degradation behavior and not considering acidity, etc., achieve good hydrophilicity, improve hydrophilicity, and excellent hydrophilicity Effects of water and cell affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

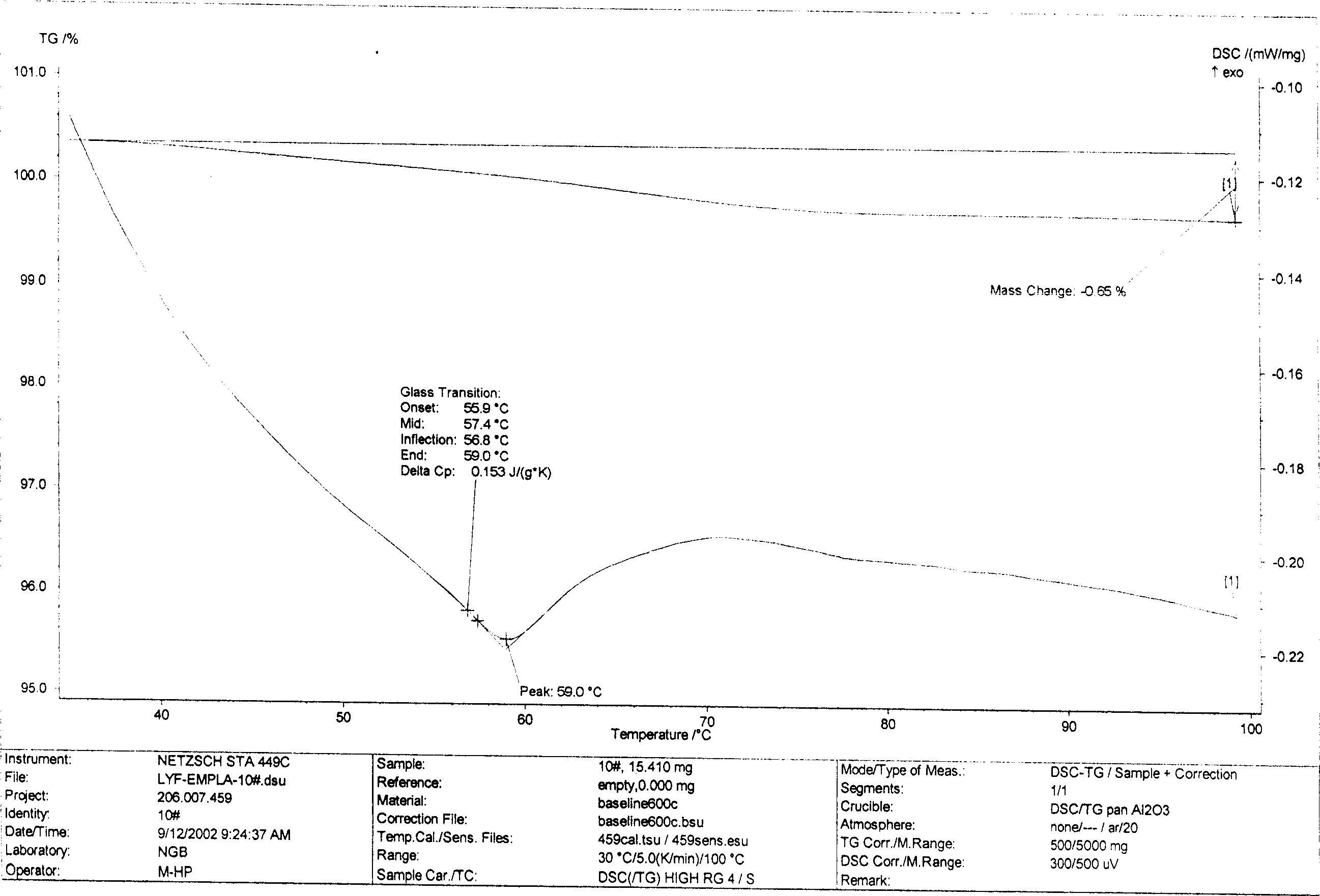

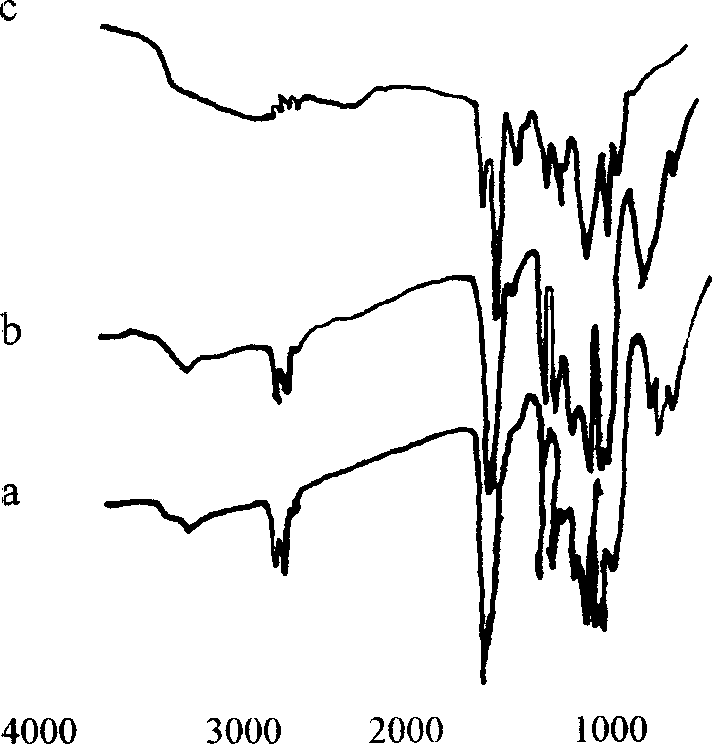

[0018] Example 1 Preparation of maleic anhydride-modified polylactic acid. Grind 5.0 grams of poly(D, L-lactic acid) (molecular weight is 200,000, static water contact angle θ=51°) and 0.5 grams of maleic anhydride into powder and mix with 15 mg of tert-butyl peroxide evenly, vacuum at room temperature Vacuum fusion seal in 15 ml ampoules after drying for 48 hours. React at 50°C for 20 hours to obtain a colorless and transparent maleic anhydride-modified polylactic acid with a static water contact angle θ=66° (measured by a CQJ-93 contact angle meter, the same below). The product was dissolved in 15 ml of tetrahydrofuran solvent and dropped into excess distilled water to collect the precipitate. Repeat the dissolution-precipitation three times. The precipitate was vacuum-dried at room temperature for 72 hours to obtain 4.2 g of colorless and transparent refined maleic anhydride-modified polylactic acid. Static water contact angle θ=40°, glass transition peak temperature T ...

Embodiment 2

[0019] Example 2 Preparation of maleic anhydride-modified polylactic acid. 5.0 grams of poly (D, L-lactic acid) (molecular weight is 2.2 million, static water contact angle θ = 51 °) and 0.5 grams of maleic anhydride and 15 mg of phthaloyl peroxide were dissolved in 15 milliliters of tetrahydrofuran solvent In a 50 ml round bottom flask, stir well to make the mixture uniform, vacuum dry at room temperature for 48 hours and then vacuum seal. React at 100°C for 10 hours to obtain a colorless or light yellow transparent maleic anhydride-modified polylactic acid with a static water contact angle θ=65° (measured by a CQJ-93 contact angle meter, the same below). The product was dissolved in 15 ml of tetrahydrofuran solvent and dropped into excess distilled water to collect the precipitate. Repeat the dissolution-precipitation three times. The precipitate was vacuum-dried at room temperature for 72 hours to obtain 4.3 g of colorless and transparent refined maleic anhydride-modified...

Embodiment 3

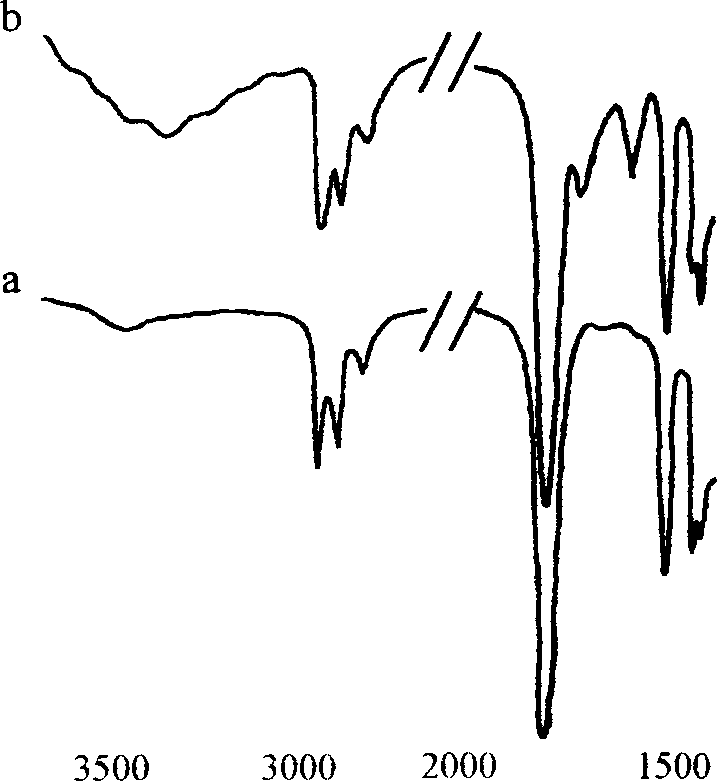

[0020]Example 3 Preparation of ethylenediamine-modified polylactic acid. Dissolve 5.0 grams of poly(D,L-lactic acid) (molecular weight: 2.2 million, static water contact angle θ=51°), 0.25 grams of maleic anhydride and 2.5 mg of tert-butyl peroxide in a 50-ml round-bottomed flask filled with 15 ml of tetrahydrofuran In, stir well to make the mixture even. Vacuum dried at room temperature for 72 hours, and the tetrahydrofuran solvent was sucked off. React at 120°C for 6 hours under the protection of nitrogen to obtain a colorless and transparent maleic anhydride-modified polylactic acid. Add 100 ml of tetrahydrofuran solvent to fully dissolve the maleic anhydride-modified polylactic acid. 0.25 g of ethylenediamine was dissolved in 5 ml of tetrahydrofuran and placed in a constant temperature water bath at 10°C. Add the tetrahydrofuran solution of maleic anhydride-modified polylactic acid dropwise into the tetrahydrofuran solution of ethylenediamine under stirring, and finish ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com